THRUST WASHER PAIR in Engine Drive Components

Engine drive components form the mechanical backbone that transfers the power of combustion into usable rotation and thrust. This article category covers the crucial elements that transmit torque, manage axial and radial loads, and stabilize motion inside diesel and gas engines—components such as crankshafts, main and thrust bearings, couplings, gear trains, and torsional vibration dampers. In heavy-duty applications like propulsion and power generation, the integrity of these parts directly determines output, efficiency, and operating safety.

Within this system, controlling axial movement is vital. Here, a THRUST WASHER PAIR defines and protects crankshaft endplay, especially in a marine engine where propeller thrust loads are continuous and variable. While engine drive components work together as a system, the THRUST WASHER PAIR is the axial safety stop that keeps the crankshaft centered under load, preserves lubrication films, and safeguards gear meshes, shaft seals, and couplings from misalignment.

Technical function of Engine Drive Components and the THRUST WASHER PAIR

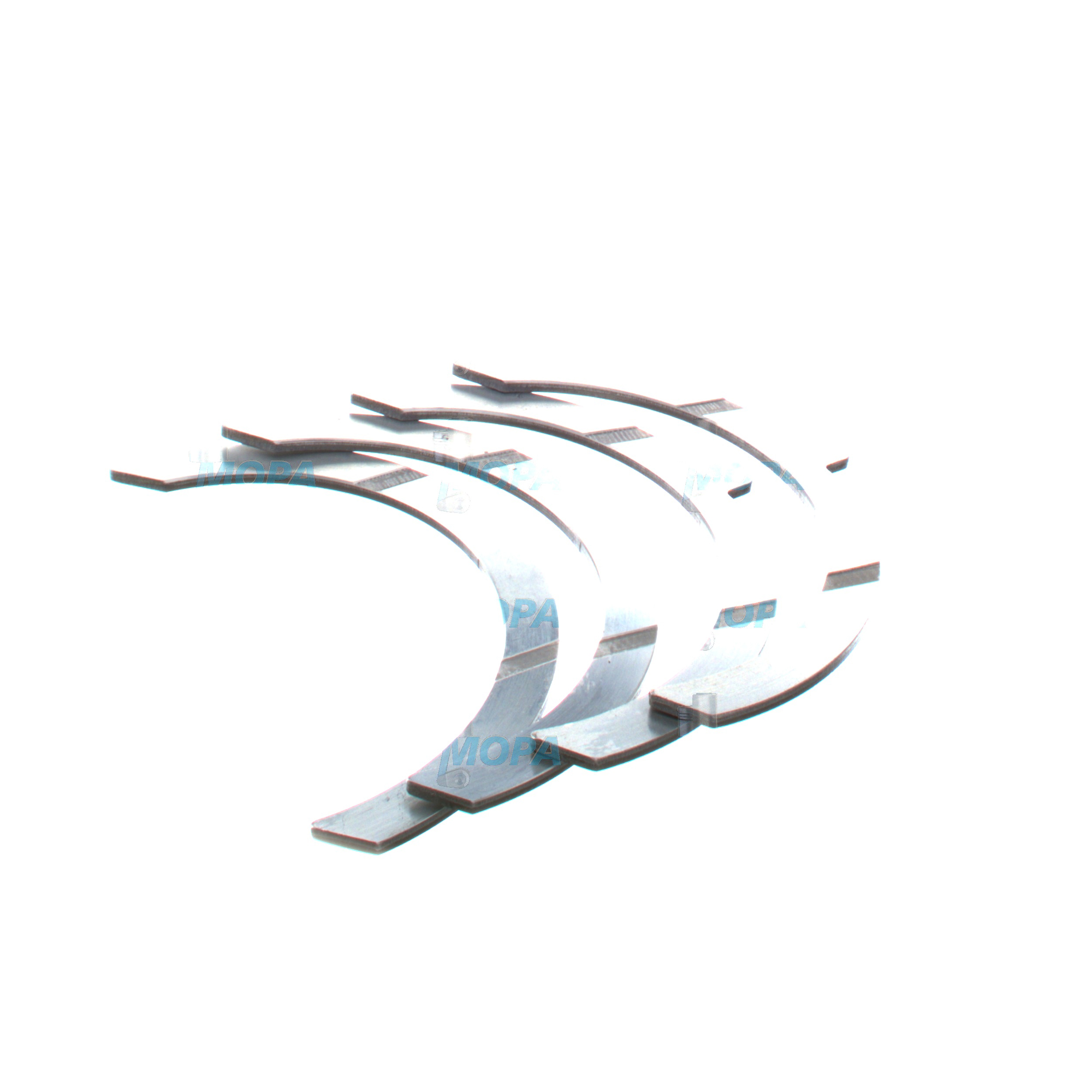

Engine drive components convert explosive or high-pressure energy into smooth, reliable rotation. Main bearings carry radial loads; the gear train and couplings transmit torque; the flywheel stabilizes speed; and the THRUST WASHER PAIR handles axial forces that push or pull the crankshaft. In a diesel engine, these axial forces arise from helical gear thrust, clutch actuation, PTO devices, or the propeller column in a marine engine. The paired thrust washers install on opposing sides of the crankshaft’s thrust cheeks, forming a lubricated bearing surface that limits end float to a narrow tolerance window while dissipating heat.

When correctly specified and maintained, a THRUST WASHER PAIR creates a hydrodynamic film that prevents metal-to-metal contact, even under transient load spikes. Typical constructions include steel- or bronze-backed washers with a soft bearing overlay (e.g., tin- or lead-based babbitt) and engineered oil grooves to stabilize the lubricant wedge. The component geometry, surface finish, and groove pattern are matched to journal diameter, oil viscosity, and expected thrust loads. In practice, end float might be controlled to a specification on the order of 0.05–0.25 mm for large engines, measured with a dial indicator while prying the crank fore and aft.

In procurement terms, selecting the right THRUST WASHER PAIR diesel engine configuration—or a THRUST WASHER PAIR marine engine setup—ensures the axial load path is robust and predictable. Sourcing a THRUST WASHER PAIR OEM parts package aligned with the engine builder’s geometry maintains the intended oil-film behavior, protects mating parts, and supports stable long-term performance.

Key characteristics and advantages of Engine Drive Components

· Engineered to transmit high torque with minimal losses.

· Precision tolerances sustain hydrodynamic lubrication.

· Materials tailored for load, temperature, and oil chemistry.

· Axial control via THRUST WASHER PAIR prevents crankshaft walk.

· Reduced vibration and noise for smoother operation.

· Lower wear rates extend overhaul intervals and service life.

· Consistent alignment protects seals, gears, and couplings.

· Measurable performance via clear fit and clearance specs.

· Optimized for fuel efficiency and emissions stability.

· Designed for safe, predictable operation under peak loads.

Importance for reliable engine operation and service life

Engine drive components are decisive for uptime and lifecycle costs. If thrust control deteriorates, the crankshaft can drift axially, altering gear contact patterns and overloading the front or rear main bearing. Symptoms include abnormal end float readings, oil temperature rises, metallic debris in filters, accelerated seal wear, and tonal gear noise. In severe cases, crank web flanges can scuff the bearing faces, leading to rapid surface distress and loss of oil film. Marine operators may see erratic shaft alignment at the coupling, higher vibration, or even trip events due to protective monitoring.

Maintaining a healthy THRUST WASHER PAIR protects the crankshaft thrust faces, stabilizes gear mesh, and prevents fretting at couplings and PTOs. It also helps keep the lube circuit clean by minimizing bearing material shedding. Left unchecked, thrust surface damage can cascade into collateral failures—damaged oil pumps, compromised seals, or gear tooth pitting—expanding repair scope and downtime. For purchasers and superintendents, the takeaway is clear: precise axial control is non-negotiable for dependable service in both diesel and gas engines.

Advantages of OEM spare parts suitable for Engine Drive Components

OEM spare parts suitable for engine drive components ensure dimensional fidelity, metallurgy, and surface finishes that match the design intent. For a THRUST WASHER PAIR OEM parts kit, that means correct backing materials, overlay composition, hardness profiles, and groove geometries—factors that govern hydrodynamic film stability under real-world loads. The result is predictable end float, consistent oil temperatures, and reduced wear rates across the entire drive train.

For budget control, the right OEM spare parts minimize rework, fit-up issues, and premature replacements. Shorter installation times and clean handover reduce dock time and rental costs for temporary power. Equally important, documented traceability and specifications streamline class compliance and maintenance records, adding operational security for shipowners and power plant operators. By preserving alignment and lubrication regimes, OEM spare parts extend overhaul intervals, sustain fuel efficiency, and protect high-value assets like crankshafts and gear sets.

· Fit-for-design geometries preserve end float and clearances.

· Proven materials and heat treatment resist scuffing and fatigue.

· Correct oil-groove patterns stabilize the lubricant wedge.

· Lower total cost of ownership through longer service intervals.

· Reliable lead times and documentation support planned outages.

MOPA — your partner for OEM spare parts Engine Drive Components

MOPA supports purchasers, shipowners, and plant operators with fast, reliable access to OEM spare parts for engine drive components, including the critical THRUST WASHER PAIR for diesel and gas engines. With deep product knowledge and a vetted supplier network, MOPA focuses on speed, quality, and security throughout the procurement process—from technical identification and cross-referencing to safe packing and express shipping.

Customers benefit from responsive sourcing, consistent specifications, and transparent documentation that reduces risk in critical-path maintenance. Whether you need a THRUST WASHER PAIR marine engine application or a THRUST WASHER PAIR diesel engine set aligned to a specific build standard, MOPA helps keep assets running efficiently and safely.

Conclusion — Engine Drive Components and the THRUST WASHER PAIR

Engine drive components determine how effectively an engine turns combustion into reliable power, and the THRUST WASHER PAIR is key to controlling axial loads that affect alignment, lubrication, and longevity. Choosing OEM spare parts suitable for engine drive components protects performance, budget, and service life—securing uptime and confidence in demanding marine and industrial operations.