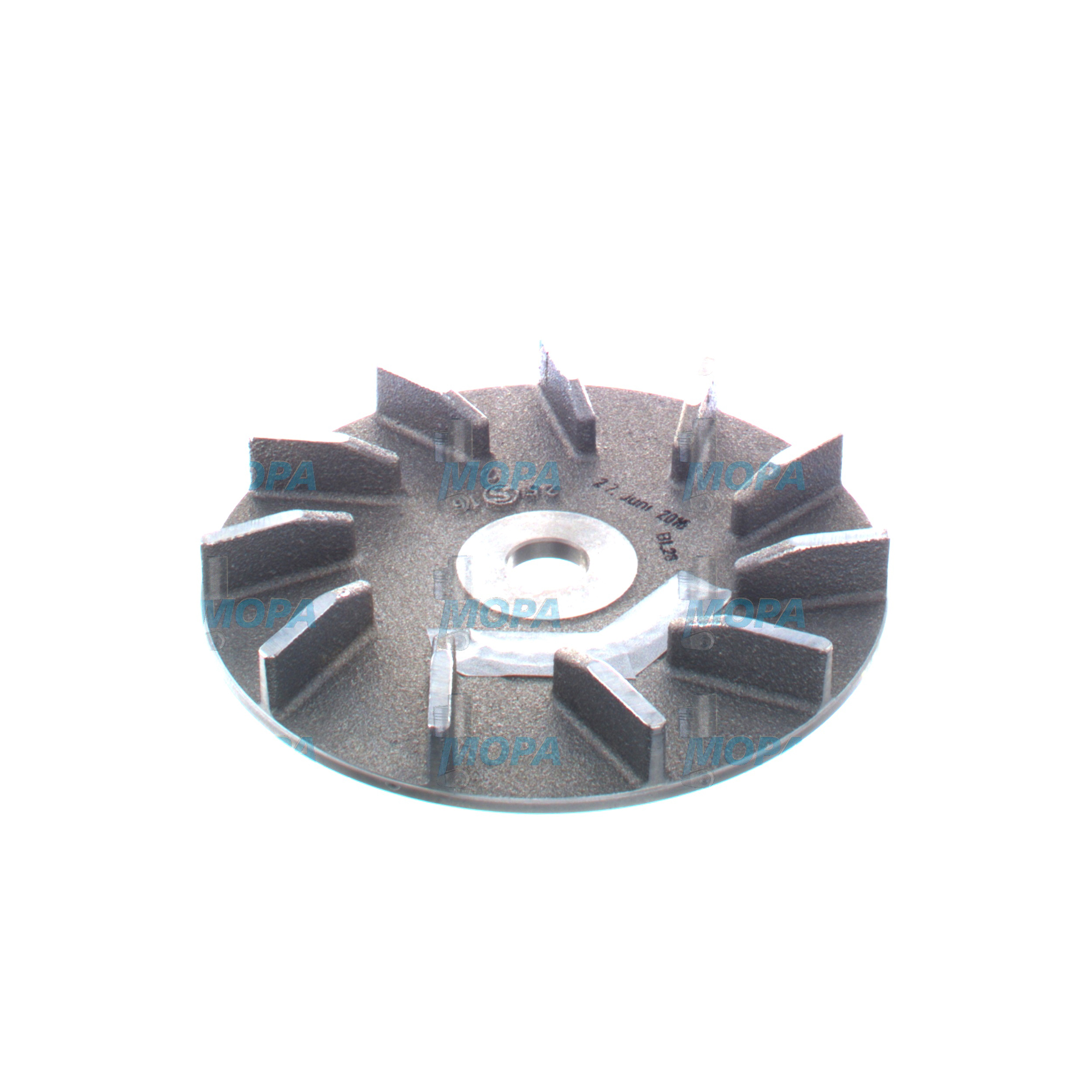

FAN PULLEY and Fan Components for Heavy-Duty Engines

The fan is a core component of the engine cooling system. Whether installed on a propulsion unit, a genset, or an auxiliary drive, the fan draws or pushes air through radiators, charge-air coolers, oil coolers, or remote heat exchangers to stabilize operating temperatures. In marine engine rooms and land-based power plants alike, a properly engineered fan ensures that coolant, lube oil, and intake air stay within design limits under high ambient temperatures and transient loads. As a rotating assembly tied to belt drive and hub geometry, the fan works hand in hand with the FAN PULLEY to deliver the airflow the engine map requires—quietly, efficiently, and reliably.

Fan fundamentals and the role of the FAN PULLEY

Technically, the fan converts shaft power into directed airflow. Blade count, chord length, pitch angle, and material stiffness define the pressure curve and volumetric flow. This aerodynamic performance must be synchronized with engine speed via the drive system. Here, the FAN PULLEY determines the speed ratio and therefore the fan’s actual working point. In a diesel engine, the combination of crankshaft pulley, tensioner, belt, and FAN PULLEY sets the rpm at which the fan delivers its rated airflow. In a marine engine with remote coolers, correct pulley sizing prevents thermal derating during maneuvering or hot-climate service.

The fan typically mounts to a hub, clutch, or directly to a shaft. Dynamic balancing keeps vibration below acceptable limits to protect bearings, brackets, and the belt drive. Material choices—such as reinforced polymers, aluminum, or coated steel—ensure dimensional stability at elevated temperatures and resistance to salt-laden air. When specified with the correct FAN PULLEY (diesel engine) and appropriate shroud/guarding, the fan achieves high static efficiency and maintains a stable cooling margin across the engine’s load profile.

- · High airflow at controlled noise levels

- · Precise balance to minimize vibration and bearing load

- · Blade geometry matched to radiator and shroud

- · Material options for heat and corrosion resistance

- · Speed optimized via the FAN PULLEY ratio

- · Stable performance in marine engine and land-based duty

- · Drop-in fit to existing hubs and guards

- · Compliance with engine-maker specifications

FAN PULLEY ratios in diesel engine cooling

Fan effectiveness depends on achieving the correct operating point on the fan curve. The fan speed is a direct function of the FAN PULLEY diameter relative to the drive pulley. Underspeed leads to insufficient airflow and creeping coolant temperatures at high load; overspeed raises noise, power draw, and premature wear while offering little extra cooling. Matching the fan’s aerodynamic design to the diesel engine’s duty cycle and the FAN PULLEY ratio ensures efficient heat rejection without wasting fuel on parasitic losses. In practice, properly sized OEM parts for the FAN PULLEY and fan assembly help maintain thermal headroom during start-up, load steps, and idling in confined spaces.

Why the fan is critical for engine reliability and service life

Cooling stability underpins the entire engine. If the fan is damaged, unbalanced, or operating at the wrong speed, coolant temperatures rise, oil film strength degrades, and component clearances shift. Overheating accelerates liner polishing, head gasket failures, turbocharger coking, and oxidation of lubricants. Prolonged thermal stress can force derating, emergency shutdowns, or even costly rebuilds. In a marine engine, insufficient ventilation or reduced cooler airflow further threatens crew safety and vessel availability. Conversely, a correctly specified fan—working with the right FAN PULLEY and belt tension—keeps EGT, coolant, and oil temperatures on target, preserves elastomer life, and protects bearings and seals across long maintenance intervals.

OEM spare parts suitable for Fan: performance, reliability, and lifecycle cost

Selecting OEM spare parts suitable for the fan brings measurable benefits. Precision manufacturing ensures consistent blade pitch, mass distribution, and hub fit, which translates into low vibration and stable airflow. When combined with an OEM-spec FAN PULLEY for OEM parts-driven diesel and gas engines, the assembly delivers the intended speed ratio and torque transmission without belt slippage or misalignment. This accuracy safeguards performance and reduces cumulative stress on brackets, water pumps, and alternator bearings.

Beyond fit and finish, OEM spare parts are validated against thermal, corrosion, and fatigue loads representative of real service, including salt-fog and high-temperature testing for marine applications. The result is predictable service life and fewer unplanned stoppages. Because the fan is a continuous parasitic load, optimized aerodynamics reduce the power required for a given airflow, supporting lower fuel consumption and lower acoustic emissions over thousands of operating hours. That efficiency, combined with extended component life, directly benefits budgets and total cost of ownership.

MOPA: fast, secure supply of OEM parts for Fan and FAN PULLEY systems

MOPA is an experienced and reliable partner for OEM spare parts suitable for the fan and related FAN PULLEY components. We move quickly—sourcing and delivering the right configuration for your diesel engine or marine engine application with minimal downtime. Our processes prioritize quality and traceability, providing secure handling and documentation throughout the trade of OEM parts for diesel and gas engines. From single fans to complete belt-drive kits with matched pulleys and tensioners, MOPA helps you maintain cooling performance and operational safety across fleets and power plants.

Conclusion: FAN PULLEY synergy with high-performance fans

The fan is fundamental to engine temperature control, and its performance is directly influenced by the FAN PULLEY ratio and drive integrity. Choosing OEM spare parts suitable for the fan ensures precise fit, durable materials, and proven performance that protect reliability, efficiency, and budgets. With MOPA as your partner, you secure swift access to OEM-grade solutions for diesel and gas engines, keeping assets cool, efficient, and ready for duty.