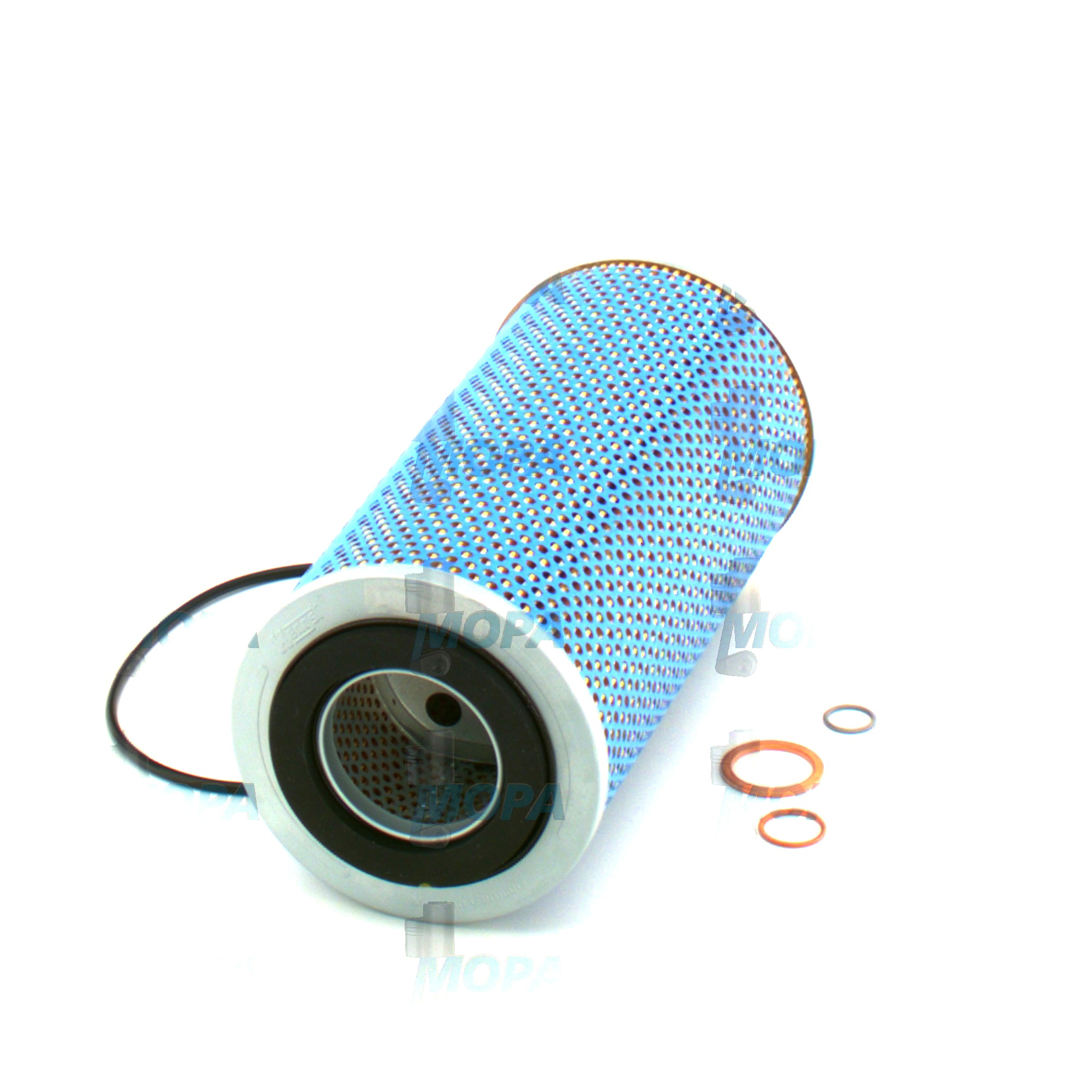

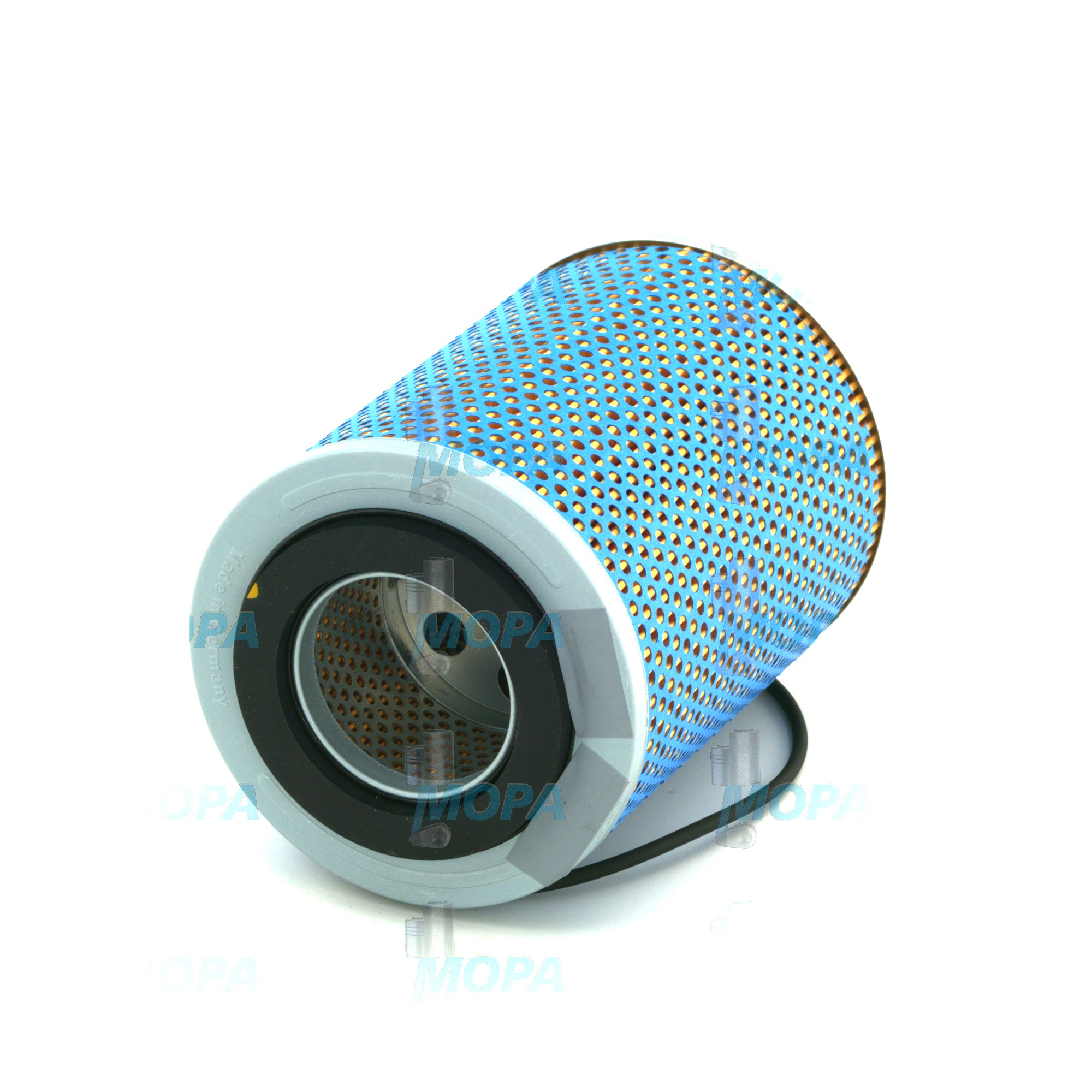

ENGINE OIL FILTER ELEMENT for the Filter category in diesel and marine engines

Filters are precision components that protect engines by removing harmful contaminants from vital media such as lubricating oil, fuel, intake air, and coolant. Within this Filter category, the ENGINE OIL FILTER ELEMENT plays a central role: it traps particles, soot, metal wear debris, and sludge from the oil circuit so that bearings, pistons, and turbochargers receive clean lubrication. For purchasers, shipowners, and technical decision-makers, selecting the right filter specification directly influences uptime, total cost of ownership, and compliance with engine-builder recommendations.

In heavy-duty diesel engine and marine engine applications, oil filtration must perform under high flow, variable viscosity, and elevated temperatures. A properly matched ENGINE OIL FILTER ELEMENT stabilizes the lubrication regime, supports energy efficiency by reducing friction losses, and helps extend oil life. As part of a broader Filter portfolio, it is the first line of defense against accelerated wear and unplanned maintenance.

Technical function of Filter components and the ENGINE OIL FILTER ELEMENT

Inside the lubrication circuit, the oil pump draws oil from the sump and pushes it through a full-flow housing that contains the ENGINE OIL FILTER ELEMENT. Modern designs use pleated cellulose, synthetic, or microglass media with graded porosity to capture a wide particle size distribution. Efficiency is often characterized by a beta ratio (per ISO 16889 multi-pass testing), while pressure drop is managed by media permeability, pleat geometry, and core support. In many diesel engine systems, a bypass (relief) valve integrated in the housing opens under high differential pressure—such as during cold starts or when the element is severely loaded—to maintain minimum oil supply to critical components.

The ENGINE OIL FILTER ELEMENT for a marine engine must combine high dirt-holding capacity with stable filtration efficiency across long service intervals. Robust end caps, metal or polymer cores with adequate collapse strength, and oil-resistant gaskets prevent channeling and bypassing. In addition, optimized flow paths reduce pressure losses, improving pump efficiency and helping maintain stable oil film thickness on bearings and cam lobes. When specified as OEM parts, the element’s dimensions, sealing profiles, and media selection are aligned with the engine maker’s flow, viscosity, and temperature envelope.

Key characteristics of a high-performance ENGINE OIL FILTER ELEMENT include filtration ratings in the 5–40 μm range for full-flow elements, thermal resistance to sustained high oil temperatures, and compatibility with modern additive packages. In larger diesel engine installations, the Filter setup may combine full-flow and bypass elements: the full-flow element removes larger particles at the pump outlet, while an auxiliary bypass filter captures fine soot to keep total contamination under control.

Key characteristics and advantages at a glance

· Stable efficiency across the service interval.

· High dirt-holding capacity for long runtime.

· Low differential pressure to protect cold-start lubrication.

· Robust collapse strength and reliable sealing.

· Media compatible with diesel engine oil chemistry.

· Precise fit for housing, cores, and end-cap interfaces.

· Supports lower wear rates and extended oil life.

Importance of Filter integrity for engine operation

Reliable filtration is essential for engine durability. If the ENGINE OIL FILTER ELEMENT is worn, overloaded, or not correctly matched, contamination levels rise quickly. Abrasive particles accelerate bearing and liner wear, increase ring groove polishing, and can damage turbocharger journals. Excessive differential pressure may trigger bypass valve opening, sending unfiltered oil to sensitive components. Over time, sludge formation thickens the oil, elevates operating temperatures, and undermines efficiency and emissions performance. For marine engine fleets with long duty cycles, the consequences are costly: higher fuel consumption due to friction, reduced component life, and avoidable downtime during port calls.

Routine condition monitoring—oil analysis (particle counts, insolubles), pressure drop tracking, and adherence to service intervals—must be paired with the correct Filter specification. Choosing the right ENGINE OIL FILTER ELEMENT reduces the risk of varnish, extends the interval between overhauls, and stabilizes lubricant performance under heavy load and variable fuel quality conditions.

Advantages of OEM spare parts suitable for Filter and ENGINE OIL FILTER ELEMENT

Using OEM spare parts suitable for the Filter category ensures that every ENGINE OIL FILTER ELEMENT meets the dimensional tolerances, media grades, and sealing requirements defined by the engine platform. This alignment matters for performance, reliability, budget, and service life:

· Consistent filtration performance validated to engine-maker standards.

· Correct bypass valve settings and flow characteristics to protect components.

· Materials engineered for thermal, chemical, and mechanical loads in service.

· Lower risk of oil leaks or channeling due to precise fit and gasket design.

· Predictable service intervals that simplify maintenance planning and cost control.

· Reduced downtime risk through proven compatibility with diesel engine and marine engine lubrication systems.

By selecting an ENGINE OIL FILTER ELEMENT as OEM parts, operators protect bearings, cams, and turbochargers from premature wear, keep oil cleanliness within target ISO codes, and support stable fuel efficiency over the engine’s lifecycle.

MOPA as your OEM partner for Filter and ENGINE OIL FILTER ELEMENT

MOPA supplies OEM spare parts for the Filter category with a strong focus on the ENGINE OIL FILTER ELEMENT used in diesel and gas engines. Customers rely on our speed of delivery, consistent quality, and secure sourcing—critical factors when schedules are tight and vessels or power plants cannot afford delays. Our portfolio covers a wide range of engine families, and our technical team supports cross-referencing, specification checks, and documentation to ensure the correct element for each lubrication system. With MOPA, purchasers and shipowners gain a dependable partner for OEM parts that protect performance and uptime.

Conclusion: Filter essentials with the ENGINE OIL FILTER ELEMENT

The Filter category is fundamental to engine health, with the ENGINE OIL FILTER ELEMENT at the core of clean, reliable lubrication. By choosing OEM spare parts suitable for this component, operators secure consistent filtration, safeguard critical hardware, and optimize lifetime operating costs.