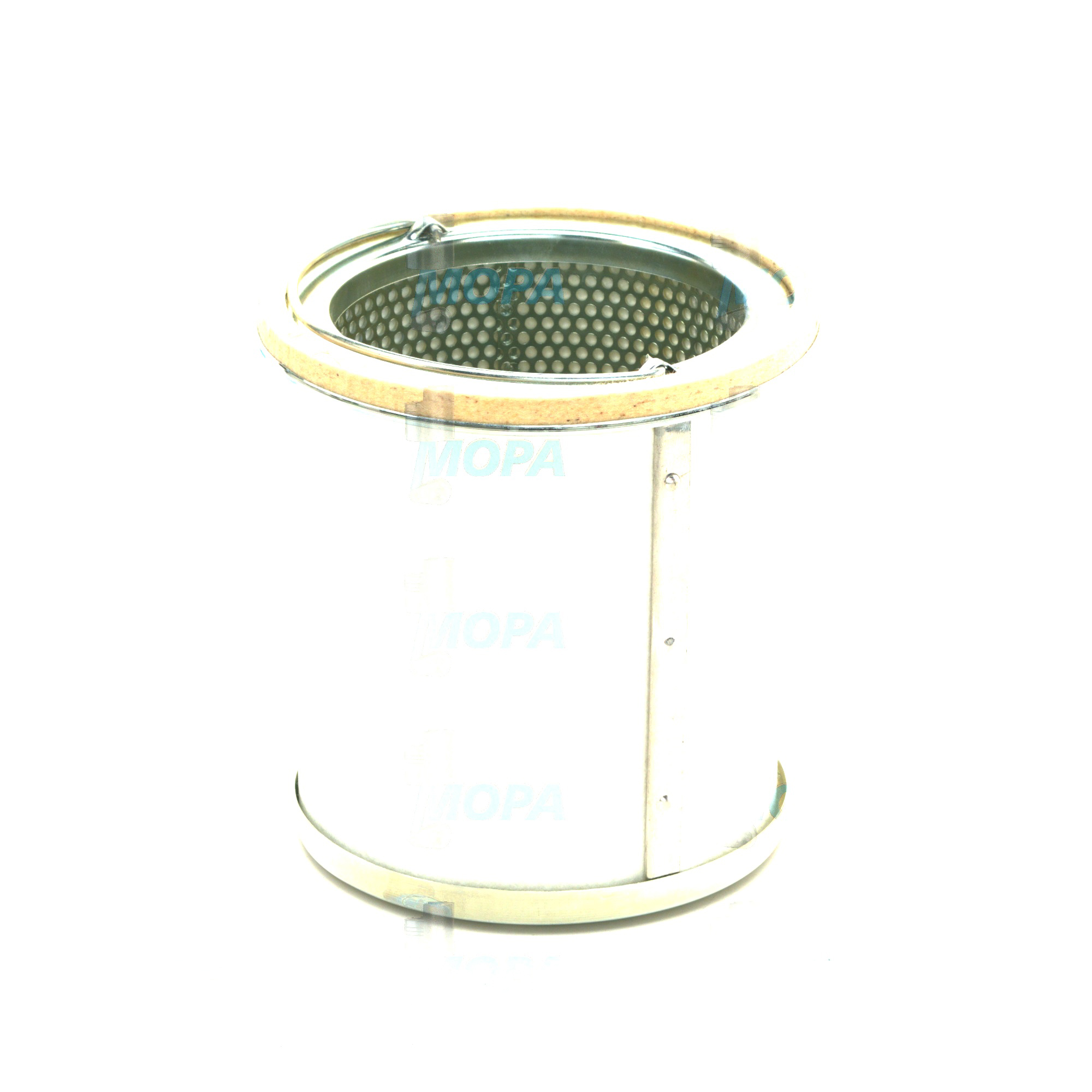

FILTER ELEMENT Filters for Engines and Power Generation

Filters are safety-critical consumables that protect every fluid and air circuit in an engine. In lube oil, fuel, intake air, and coolant systems, the FILTER ELEMENT is the replaceable core that traps abrasive particles, water, soot, and chemical by‑products before they reach precision components. Whether you operate a high-speed genset, a medium-speed propulsion unit, or a two-stroke low-speed main engine, the right FILTER ELEMENT preserves clearances, stabilizes pressures, and keeps combustion clean—directly impacting uptime, fuel economy, and compliance.

Within the article category Filter, you will find elements engineered for marine, diesel, and gas engines across a wide range of operating conditions—from heavy fuel and distillate service to LNG and dual-fuel plants. Selection is not only about size; it is about filtration efficiency, dirt‑holding capacity, pressure drop behavior, media compatibility, and the correct bypass setting for the application.

Technical Function of a FILTER ELEMENT in Marine and Diesel Engines

A FILTER ELEMENT is a precision-built cartridge that forces process media through a calibrated matrix—typically cellulose, micro‑glass, or multilayer synthetic fibers—to separate contaminants at defined micron ratings. In a lube oil circuit, the element maintains ISO 4406 cleanliness targets to protect bearings, cam lobes, and turbocharger journals. In a fuel system, the FILTER ELEMENT diesel engine configuration removes fine particulates (including catalytic fines Al+Si) and coalesces water to safeguard high‑pressure pumps and injectors. For intake systems, high‑capacity air elements capture salt crystals and dust before they erode compressors and cylinders, while coolant elements can stabilize additive dosing and trap corrosion products.

Performance is quantified by Beta ratio (per ISO 16889), differential pressure, and collapse strength. High Beta efficiency (e.g., ß10 ≥ 200) means the element consistently removes particles at the target size with minimal re‑release. Properly matched pleat geometry and media surface area deliver high dirt‑holding capacity without starving the circuit; this keeps differential pressure within the safe operating window and avoids premature bypass. In a FILTER ELEMENT marine engine fuel module, dual‑stage designs combine a fine particle stage with a hydrophobic or coalescing layer to reduce free water content and prevent injector cavitation. Seal materials (NBR, FKM) must be compatible with ULSD, biodiesel blends, HFO, or gas condensates. When sourced as FILTER ELEMENT OEM parts, valve calibrations and collapse ratings are aligned with the engine maker’s flow and pressure profile.

- · Calibrated micron ratings for oil, fuel, air, and coolant.

- · High Beta efficiency for stable cleanliness over service life.

- · Low pressure drop with large dirt‑holding capacity.

- · Media options: cellulose, micro‑glass, synthetic, water‑separating.

- · Robust end caps and cores with high collapse resistance.

- · Correct bypass valve settings for each engine circuit.

- · Seal materials matched to diesel, HFO, gas, and biofuel exposure.

- · Tested per ISO 16889; supports ISO 4406 cleanliness targets.

Why Filters Matter: Reliability, Efficiency, and Safety

Cleanliness is a leading indicator of engine health. Abrasive wear accelerates exponentially once contamination thresholds are exceeded. If a FILTER ELEMENT is overloaded, damaged, or mismatched, several risks emerge: unfiltered bypass flow can score journals and rings; injector needle and seat wear raises return flow and distorts spray patterns; turbo compressors erode from salt and dust ingestion; and oxidation by‑products in lube oil thicken, forcing higher pump loads and fuel consumption. Water breakthrough in fuel can trigger corrosion, micro‑pitting, and loss of injection pressure. In coolant loops, particulate circulation undermines heat transfer and can cause localized hot spots and liner cavitation.

Conversely, maintaining the correct FILTER ELEMENT for diesel engine and gas engine service stabilizes operating pressures, protects aftertreatment, and keeps combustion consistent. The result is predictable maintenance intervals, lower total cost per running hour, and reduced risk of unplanned off‑hire.

Advantages of OEM Spare Parts Suitable for Filter

Choosing OEM spare parts suitable for Filter ensures that media efficiency, pleat stability, adhesive systems, and valve settings match the engine’s flow dynamics. This alignment is critical in high-load regimes where pressure pulses and viscosity shifts can deform inferior constructions. With OEM spare parts, the FILTER ELEMENT OEM parts specification is validated for collapse pressure, thermal resistance, and fuel/oil compatibility, supporting emissions compliance and long component life.

Value for performance, reliability, budget, and service life

Procurement decisions affect more than purchase price. Correctly specified OEM spare parts minimize wear on high-value components—pumps, injectors, bearings, turbochargers—reducing overhaul scope and downtime. Consistent filtration avoids gradual efficiency losses that raise specific fuel oil consumption. Extended, predictable service life and clean change‑outs reduce labor time and environmental exposure onboard. Documentation and traceability streamline audits and class requirements.

MOPA: Your Partner for FILTER ELEMENT OEM Parts

MOPA supplies OEM spare parts for Filter across leading diesel and gas engine platforms. As a trading partner to shipowners, yards, and power producers, we focus on speed, quality, and security: rapid identification by engine model and part number, fast global dispatch, and dependable sourcing with full traceability. Our team understands the technical nuances of a FILTER ELEMENT marine engine setup—fuel cleanliness targets, bypass calibration, seal material compatibility—and helps you select the right element for each circuit and operating profile.

From emergency deliveries to framework agreements, MOPA secures the FILTER ELEMENT OEM parts you need to keep fleets running efficiently and safely, with consistent performance across all units in your portfolio.

Conclusion

Filters are mission‑critical consumables, and the FILTER ELEMENT is the heart of each filtration stage that protects your engine’s oil, fuel, air, and coolant circuits. Selecting OEM spare parts suitable for Filter preserves performance, reduces risk, and extends service life—delivering reliable operation and predictable costs for marine and diesel applications.