OIL FILTER and Filter Solutions for Diesel and Marine Engines

Filters are precision-engineered components that protect every critical circuit in an engine. Within the category “Filter,” you will find the full spectrum of elements that keep oil, fuel, air, and coolant free from harmful contaminants. In heavy-duty diesel engine and marine engine environments, correct filtration is a decisive factor for stable lubrication, efficient combustion, low emissions, and long service intervals. An OIL FILTER is the centerpiece of the lubrication loop, but high-performance fuel filters, air intake filters, and coolant filters work together to preserve engine health under continuous load and variable operating conditions.

From coastal vessels and power generation sets to industrial compressors, engines rely on filters to trap wear particles, soot, water droplets, and silica dust before they cause abrasion, clog injector nozzles, score cylinder liners, or starve bearings. Selecting the right filter type, media, and capacity is therefore a procurement decision with immediate impact on uptime, total cost of ownership, and safety.

Technical Function: OIL FILTER Performance in Diesel and Marine Engines

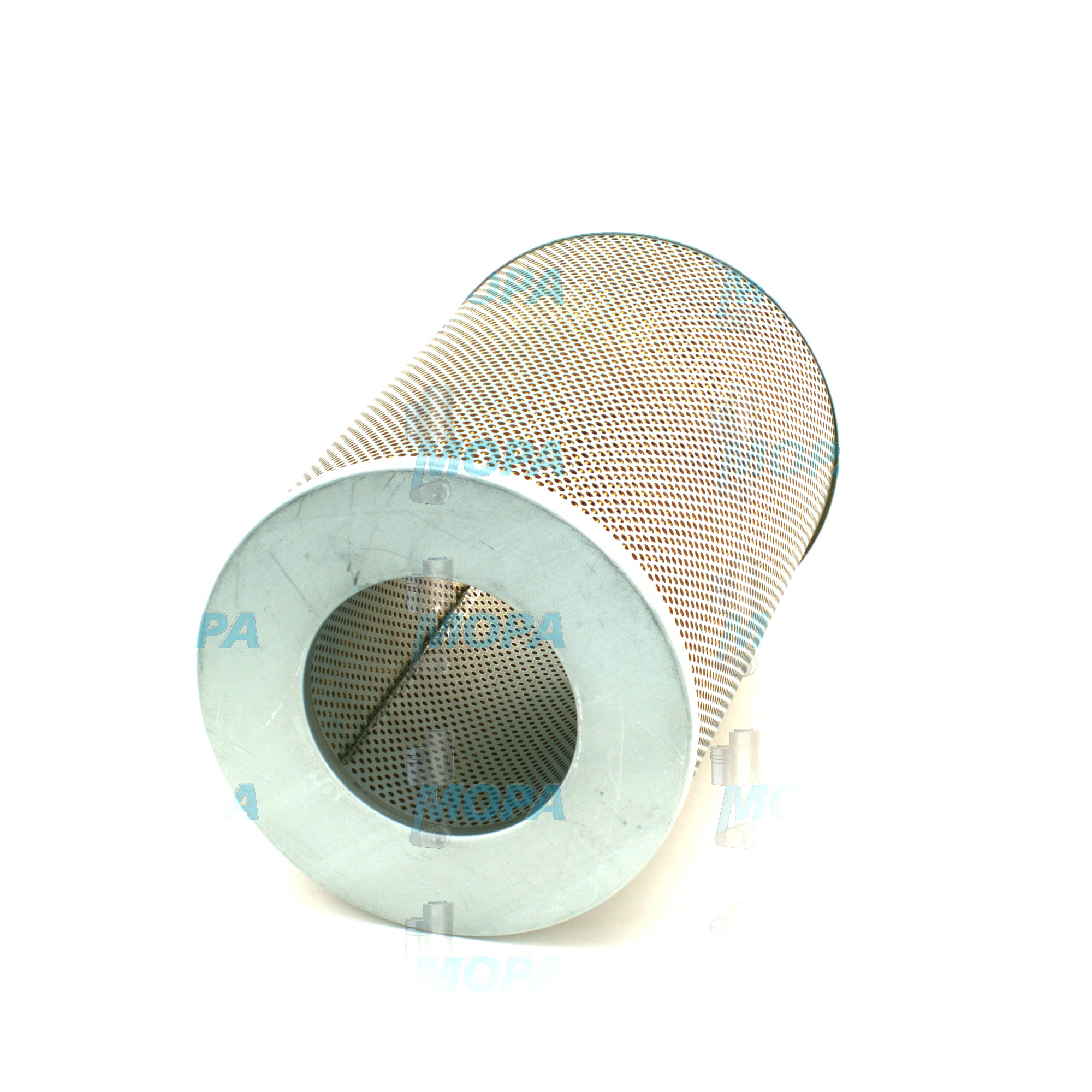

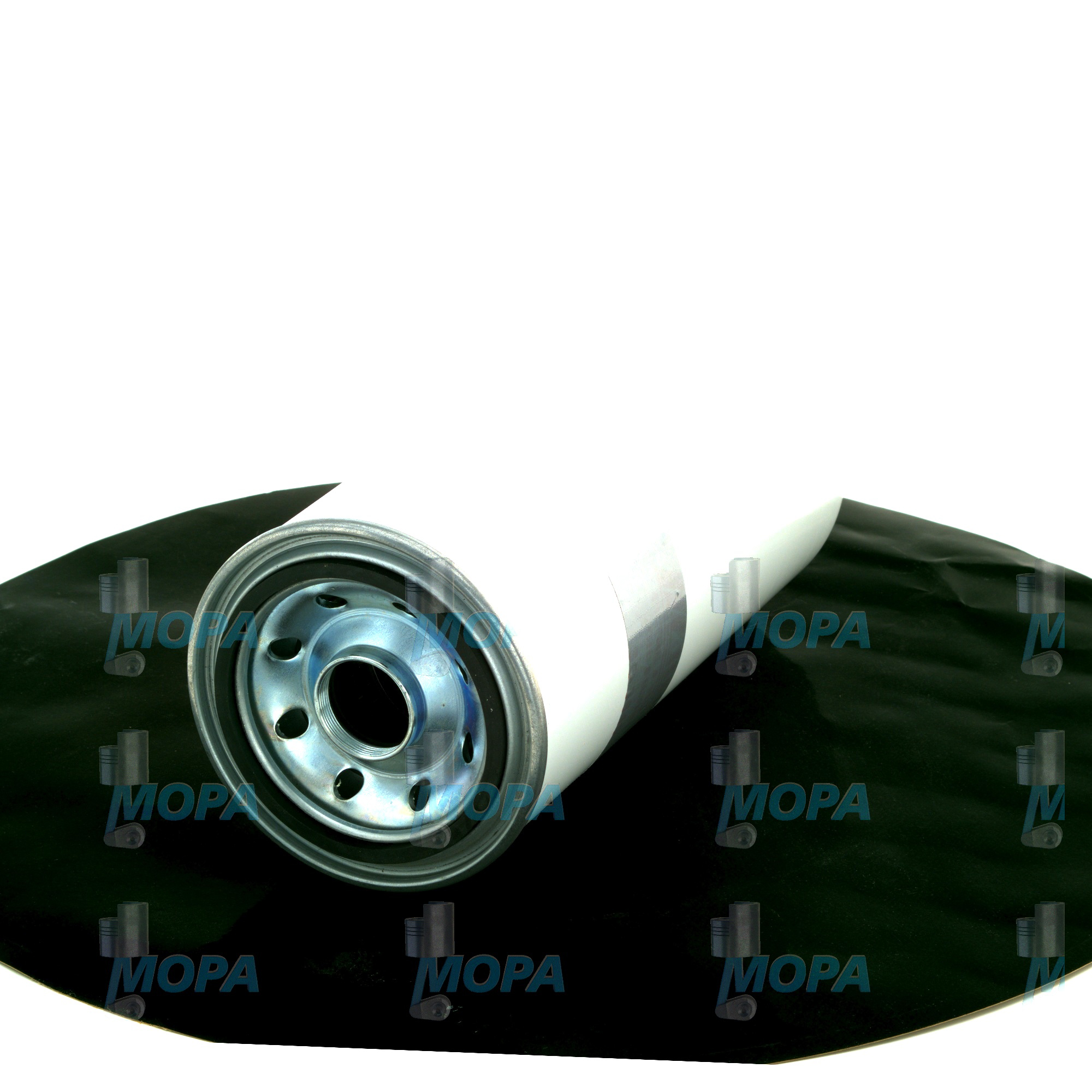

The OIL FILTER in a diesel engine or marine engine sits on the pressure side of the lubrication circuit, downstream of the oil pump. Its primary task is to capture particles generated by normal wear (iron, copper, aluminum), combustion byproducts (soot, oxidation residues), and ingested contaminants (silica, dust). Modern full-flow filters often combine multi-layer media—cellulose, synthetic, or glass fiber—with graded porosity to maximize dirt-holding capacity while maintaining low differential pressure. Many systems pair a full-flow OIL FILTER with a bypass or duplex arrangement for fine polishing filtration during continuous operation.

Critical design features include an anti-drainback valve to prevent dry starts, a stable bypass valve to protect oil flow during cold starts or high load, and robust end caps and center tubes that resist collapse at peak flow. Key performance metrics are micron rating and Beta ratio (multi-pass efficiency), dirt-holding capacity (grams), collapse pressure, and thermal/chemical compatibility with the oil type and additive package.

In marine engine duty, the OIL FILTER must perform reliably despite long running hours, fuel quality variability, and elevated soot loads. For high-output diesel engine platforms with turbochargers, clean oil ensures rotor balance and bearing protection. In addition, complementary filters across the engine—fuel/water separators, final fuel filters, air filters with high dust-load tolerance, and coolant filters with inhibitor charge—work as a system to sustain stable performance, clean combustion, and corrosion control.

- · High dirt-holding capacity for long service intervals.

- · Low and stable differential pressure across the media.

- · Correct micron rating and high Beta efficiency (multi-pass).

- · Durable media and end caps for high-flow, high-vibration duty.

- · Reliable anti-drainback and calibrated bypass valves.

- · Corrosion-resistant housings and seal compatibility.

- · Fit and performance aligned with OEM parts specifications.

Importance for Engine Operation: Why Filters Are Mission-Critical

Healthy filtration is fundamental to engine reliability and service life. A degraded or overloaded OIL FILTER allows abrasive particles to circulate, accelerating bearing wear, cam/follower scuffing, and piston ring groove erosion. Excessive restriction across a clogged element can force bypass events, delivering unfiltered oil to sensitive components and risking turbocharger damage. Poorly filtered fuel promotes injector tip erosion, uneven spray patterns, higher specific fuel consumption, and increased smoke. In the air path, compromised intake filters raise dust ingestion, leading to compressor wheel erosion and liner scoring. On the cooling side, ineffective coolant filtration contributes to solder bloom, water pump seal wear, and silicate gel formation, ultimately causing hotspots and head gasket stress.

Typical warning signs include rising differential pressure, shortened oil life, frequent injector maintenance, and elevated iron/silicon counts in oil analysis. Keeping filters in top condition stabilizes viscosity, protects additive performance, reduces varnish formation, and supports consistent emissions compliance—especially important in regulated marine zones and stationary power applications.

Advantages of OEM Spare Parts Suitable for Filter and OIL FILTER

Using OEM spare parts suitable for your Filter portfolio—especially the OIL FILTER—directly supports performance, reliability, budget control, and service life. These parts are engineered to the same dimensional envelopes and flow characteristics as the equipment design intent, ensuring proper sealing, correct bypass valve calibration, and predictable multi-pass efficiency. That means fewer unplanned shutdowns, lower risk of oil starvation at cold start, and consistent protection across full load ranges.

From a cost perspective, stable filtration efficiency extends oil change intervals, reduces component wear, and minimizes fuel system and turbocharger repairs—key levers in total cost of ownership. For fleet operators standardizing across diesel engine platforms, OEM spare parts suitable for OIL FILTER elements help maintain consistent maintenance practices, simplify inventory, and reduce procurement complexity. Technical documentation and traceability further support condition-based maintenance and align with compliance expectations in marine and industrial sectors.

For mission-critical operations, matching the right OIL FILTER OEM parts to ambient conditions, duty cycle, and fuel type ensures the filtration system can handle soot loading, thermal cycling, and pressure pulsations without media fatigue or seal failures. The result is predictable performance, longer service intervals, and a clear path to engine longevity.

MOPA: Experienced, Fast, and Secure Partner for OEM Parts

MOPA is a reliable partner for OEM spare parts in the Filter category, including OIL FILTER elements for diesel and gas engines. With deep product knowledge and a focused supplier network, MOPA delivers speed in sourcing, consistent quality, and trading security—covering traceability, documentation, and correct cross-references to your engine type and serial range. Our team supports purchasers, shipowners, and technical decision-makers with accurate identification, short lead times, and logistics solutions suitable for dockside deliveries and remote sites alike.

Conclusion: OIL FILTER and Filter Category at a Glance

Effective filters—led by a precisely matched OIL FILTER—are essential to protect lubrication, maintain efficiency, and extend the service life of diesel and marine engines. Choosing OEM spare parts suitable for Filter components secures consistent fit, calibrated performance, and dependable protection across demanding duty cycles.

MOPA combines technical expertise with rapid, secure supply of OEM parts so your engines operate with clean oil, clean fuel, and clean air—shift after shift, voyage after voyage.