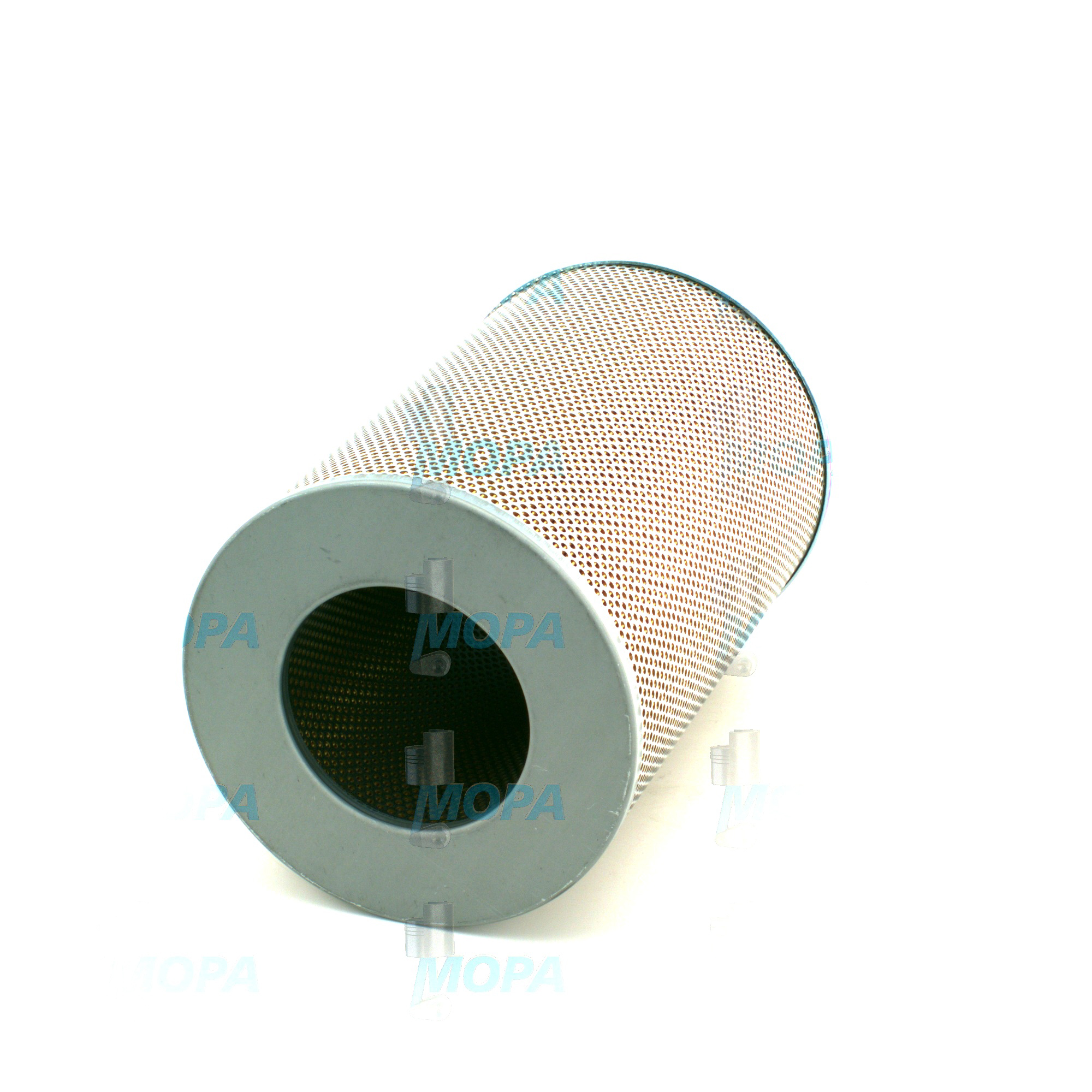

OIL FILTER ELEMENT Filters for Marine and Diesel Engines

Filters are fundamental components that keep engines clean, protected, and efficient. In heavy-duty applications—from oceangoing vessels and power plants to industrial gensets—filters separate harmful contaminants from operating fluids and air. Within this category, the OIL FILTER ELEMENT is a cornerstone of engine reliability: it removes soot, metal particles, varnish, and dirt from the lubricating circuit so that bearings, camshafts, turbochargers, and hydraulic actuators receive clean oil at the correct pressure. Without effective filtration, even high-spec lubricants cannot prevent accelerated wear and costly downtime.

OIL FILTER ELEMENT function in diesel engine and marine engine lubrication systems

In every diesel engine and marine engine, the OIL FILTER ELEMENT sits in the lube-oil circuit downstream of the pump and upstream of critical components. Its job is to trap particles across a defined micron range—often 5–25 µm(c)—while maintaining sufficient flow and minimal pressure drop. High-quality elements use multi-layer cellulose or synthetic microglass media, supported by a stable core and end caps that prevent bypassing. A correctly calibrated bypass valve ensures that, in the event of a severe blockage or cold start with high oil viscosity, the engine still receives oil flow to avert catastrophic starvation.

Performance hinges on three parameters: filtration efficiency (often described by Beta ratios), dirt-holding capacity, and differential pressure. A well-engineered OIL FILTER ELEMENT in OEM parts quality balances these factors to keep oil clean over the intended service interval, even under high soot loading typical of modern combustion and slow-speed operation. For marine engine duty cycles, the element must withstand thermal cycling, pulsating flow, and potential fuel dilution of the oil, all while protecting tight-clearance components such as main bearings and turbocharger journals.

OIL FILTER ELEMENT OEM parts: media design, flow stability, and protection

Advanced pleat geometry prevents channeling and maintains effective area under high flow, while resin and binder formulations resist collapse at elevated temperatures. Anti-drainback features can help maintain prime in certain layouts, and robust gaskets/elastomers (e.g., NBR or FKM) preserve sealing integrity against various oil chemistries. Specified collapse strength and burst pressure ratings ensure the element remains intact during transients such as cold starts or rapid load changes common in propulsion and auxiliary engines.

- · High filtration efficiency with defined Beta ratios

- · Large dirt-holding capacity for long service intervals

- · Low, stable differential pressure at rated flow

- · Robust core, end caps, and adhesives for thermal stability

- · Precisely calibrated bypass valve settings

- · Compatible sealing materials (NBR/FKM) for modern oils

- · Reliable performance in diesel engine and marine engine duty

- · Traceable specifications that match OEM parts requirements

Why the Filter category—especially the OIL FILTER ELEMENT—is critical for engine reliability

Clean oil is the lifeblood of any engine. When an OIL FILTER ELEMENT deteriorates or becomes overloaded, contaminants circulate and act like abrasives, leading to bearing scoring, increased blow-by, cam and lifter wear, and turbocharger damage. Excessive differential pressure can force the system into bypass mode, sending unfiltered oil to precision components. The upshot is higher fuel consumption due to friction losses, shorter overhaul intervals, and a greater risk of unplanned stoppages—high-impact events for shipowners and power producers.

Regular trending of pressure drop across the filter, adherence to service intervals, and correct sizing are essential. Engines operating on heavy loads or with extended oil drain strategies need elements with proven dirt-holding capacity and thermal resilience. In multi-filter racks (duplex systems), matching elements and correct changeover procedures ensure uninterrupted filtration during operation—vital in marine engine applications where uptime is non-negotiable.

Advantages of OEM spare parts suitable for Filter and OIL FILTER ELEMENT

Choosing OEM spare parts suitable for filters—particularly for the OIL FILTER ELEMENT—directly impacts performance, lifecycle cost, and risk management. These parts are engineered to the engine maker’s specifications for efficiency, collapse strength, and bypass calibration. Dimensional accuracy ensures the element seats correctly, seals properly, and delivers the intended flow profile without channeling or media fatigue.

For purchasers and technical decision-makers, the benefits are concrete:

- · Consistent filtration efficiency aligned with engine design

- · Stable differential pressure that protects pumps and galleries

- · Materials verified for thermal, chemical, and mechanical loads

- · Drop-in fit that preserves housing integrity and sealing

- · Extended component life and optimized service intervals

- · Lower total cost of ownership through fewer failures and less downtime

- · Support for emissions compliance and oil cleanliness targets

- · Clear traceability and documentation throughout the supply chain

In short, OEM spare parts suitable for the OIL FILTER ELEMENT safeguard engine performance, protect the budget by reducing unplanned maintenance, and extend the service life of high-value assets.

MOPA as a partner for OEM OIL FILTER ELEMENT and Filter solutions

MOPA is a seasoned partner for OEM spare parts across the Filter category, with a dedicated focus on the OIL FILTER ELEMENT for diesel and gas engines. Customers value fast response times, dependable availability, and rigorous quality control. From marine engine propulsion sets to auxiliary gensets and land-based power units, MOPA streamlines the sourcing process with precise cross-referencing, technical clarification, and secure logistics.

Speed, quality, and security define MOPA’s approach: quick quotations, short lead times, and verified sourcing provide confidence in each transaction. Packaging integrity, documentation, and batch traceability support compliance and smooth audits. Whether you need a single critical element or a consolidated spare parts package, MOPA helps keep fleets and plants running with minimum downtime.

Conclusion: OIL FILTER ELEMENT Filters protect performance and uptime

The OIL FILTER ELEMENT is a vital member of the Filter category, ensuring clean lubrication, stable pressures, and long component life in diesel engine and marine engine applications. Selecting OEM spare parts suitable for this element preserves performance, reliability, and service life—while protecting budgets through reduced risk and fewer interruptions.