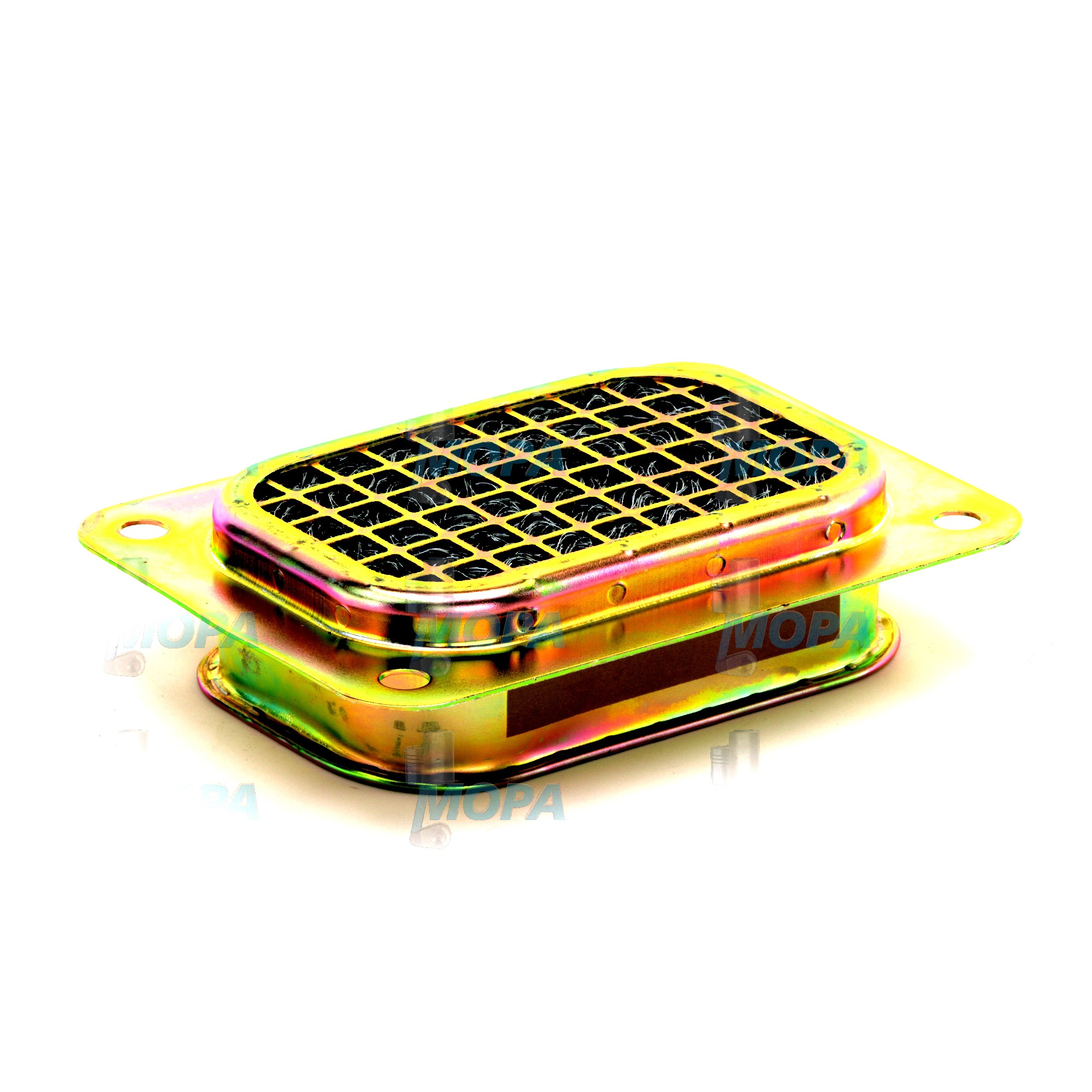

OIL SEPARATOR Filters for Marine, Diesel and Gas Engines

Filters are precision-engineered components that safeguard engines by removing contaminants from air, fuel, oil and crankcase gases. In heavy-duty service—whether on a vessel at sea or a power plant on land—filters stabilize operating conditions, protect sensitive components and help sustain efficiency across long service intervals. Within this category, the OIL SEPARATOR stands out as a specialized filter that extracts oil mist from blow‑by gases, returning clean air to the intake or ventilation path and clean oil back to the sump. Together, filters and OIL SEPARATOR units protect turbochargers, injectors, bearings and exhaust aftertreatment systems, keeping marine engine, diesel engine and gas engine platforms reliable and compliant.

Filter fundamentals and OIL SEPARATOR function in marine and diesel engines

In a combustion engine, every medium that enters or circulates through the system must be conditioned. Air filters prevent particles from eroding compressor wheels and cylinder surfaces. Fuel filters and water separators remove fine solids and free/emulsified water that would otherwise damage high-pressure pumps and nozzles. Lube oil filters capture soot, metal wear particles and sludge before they reach bearings and cam surfaces. Complementing these, the OIL SEPARATOR handles crankcase ventilation: it strips oil droplets from blow‑by gases using coalescing media or centrifugal force, then drains the recovered oil back to the crankcase, minimizing consumption and keeping the intake tract clean.

In a marine engine with high continuous loads, an OIL SEPARATOR reduces engine room contamination and protects downstream components such as charge‑air coolers from oil fouling. On a diesel engine in variable-duty cycles, it stabilizes crankcase pressure and mitigates seal leakage. Specified correctly as OIL SEPARATOR OEM parts, the unit delivers predictable separation efficiency at the rated blow‑by flow while maintaining a low pressure drop to avoid stressing seals and breather valves.

Performance-relevant parameters include micron rating and efficiency (coalescing stages often target sub‑micron aerosols), dirt-holding capacity, allowable differential pressure, media compatibility with oil additives, and temperature resistance. High-quality filters and OIL SEPARATOR assemblies integrate robust housings, precise bypass or check valves, and reliable seals that maintain integrity under vibration, thermal cycling and high sulfur or low‑BN oil conditions typical of marine duty.

- · High separation efficiency for sub‑micron oil aerosols.

- · Low and stable differential pressure across the service interval.

- · Large dirt-holding capacity for extended uptime.

- · Chemical- and temperature-resistant filter media.

- · Robust sealing and vibration-resistant construction.

- · Precise fit and performance when specified as OIL SEPARATOR OEM parts.

- · Efficient oil drain-back to reduce consumption and waste.

- · Support for emissions control and cleaner engine compartments.

Why the Filter category is critical for engine reliability and service life

Clean media flow is fundamental to engine longevity. Airborne silica or salt crystals that bypass an air filter can score cylinders and heat exchangers. Fuel contamination accelerates injector wear, disrupts spray patterns and elevates BSFC. Degraded lube oil accelerates bearing fatigue and varnish formation. When an OIL SEPARATOR is saturated or damaged, crankcase pressure can rise, forcing oil past seals and gaskets, causing leaks, oil carryover and elevated intake deposits. This leads to turbo fouling, reduced charge‑air efficiency and higher exhaust temperatures. In extreme cases, mist accumulation may raise a fire risk in engine rooms.

Operational symptoms of compromised filters include unstable idle, reduced power, higher fuel consumption, rising exhaust opacity, increasing differential pressure readings and unexpected make‑up oil demand. To prevent these issues, monitoring Δp indicators, observing blow‑by trends, verifying OIL SEPARATOR drain functionality and following condition-based or hour-based change intervals are best practices—especially for vessels operating long between-port runs or power plants on continuous base load.

Advantages of OEM spare parts suitable for Filter applications

Specifying OEM spare parts for filters—including the OIL SEPARATOR diesel engine breather—ensures the media, housing and seals match the engine maker’s flow, efficiency and durability targets. Consistent micron ratings and validated coalescing performance provide the same separation efficiency batch after batch, sustaining turbocharger cleanliness, injector protection and bearing life. Precision fitment reduces installation time and eliminates the risk of leaks or bypass caused by dimensional variance.

From a budget perspective, correct filtration preserves engine efficiency, extends component service life and reduces unplanned downtime—far outweighing the purchase price difference. Tested OIL SEPARATOR OEM parts also support compliance with class or fleet standards by offering documented performance, traceable production and predictable change intervals that simplify maintenance planning across multiple vessels or sites.

How OEM filter choices underpin performance and uptime

Reliable filters stabilize differential pressure, maintain clean combustion and protect aftertreatment systems. For crankcase systems, a properly matched OIL SEPARATOR marine engine unit keeps recirculated gases clean, reduces oil consumption and maintains breather flow under heavy seas or high tilt angles. This leads to lower emissions, fewer cleaning interventions and longer intervals between turbocharger and cooler maintenance.

MOPA: fast, secure supply of OEM Filters and OIL SEPARATOR parts

MOPA is an experienced partner for OEM spare parts in the Filter category, including OIL SEPARATOR assemblies and service elements for diesel and gas engines. We focus on speed, quality and security in every transaction—supporting urgent AOG-style dispatches for vessels, consolidated kits for scheduled dockings, and batch-traceable deliveries for power plants. Our team helps you select the right OIL SEPARATOR OEM parts based on blow‑by flow, target efficiency and allowable Δp, and aligns filters across air, fuel and lube circuits to your maintenance strategy.

Whether you operate a single marine engine or a diversified fleet, MOPA streamlines sourcing, documentation and logistics so your engines keep running at specification with minimal downtime and clear cost control.

Conclusion

Filters—and especially the OIL SEPARATOR—are essential to clean media management, stable crankcase ventilation and overall engine health. Selecting OEM spare parts suitable for the Filter category protects performance, extends service life and optimizes total operating cost. With MOPA, you gain a swift, reliable supply chain for OIL SEPARATOR OEM parts and a technical partner focused on keeping your diesel and gas engines operating at their best.