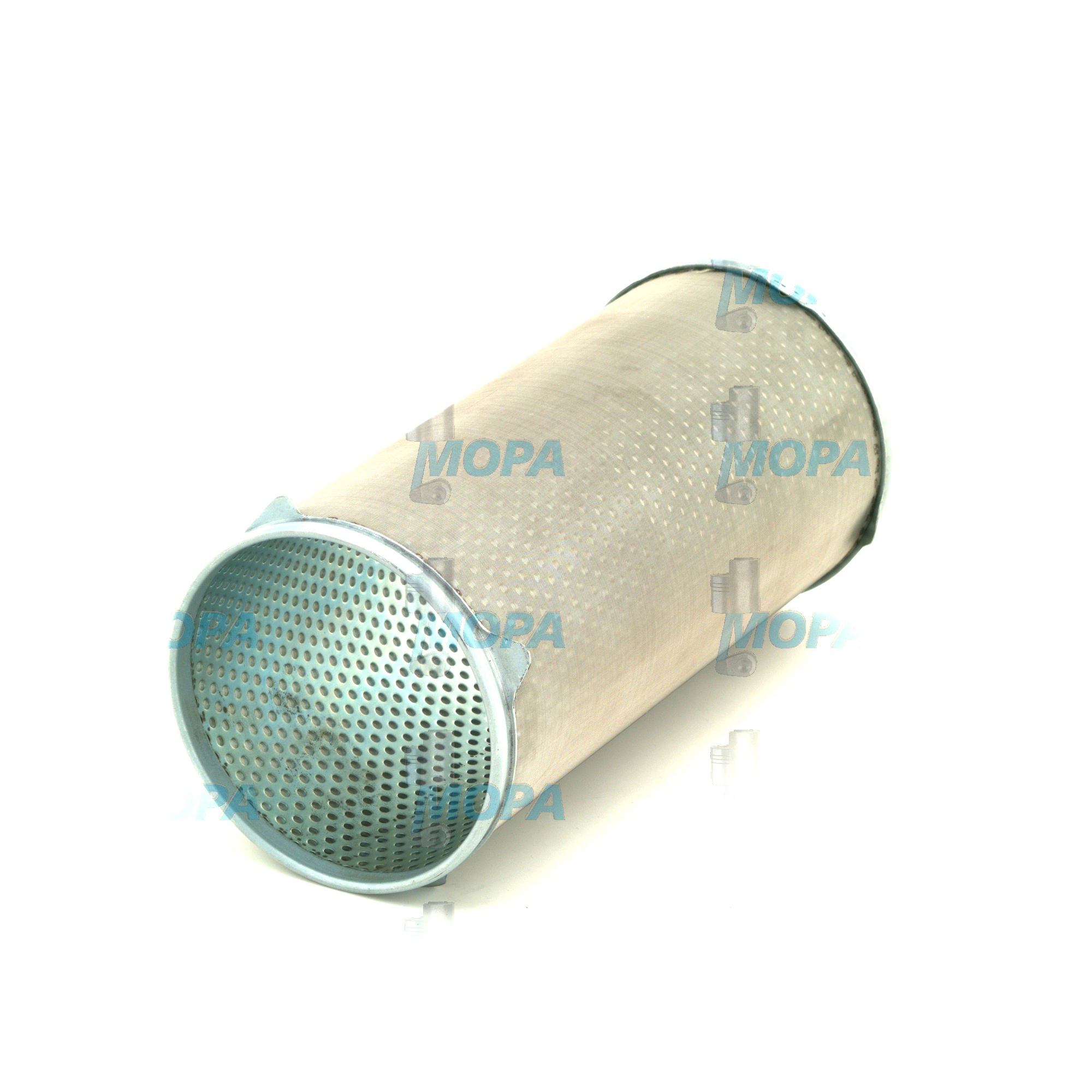

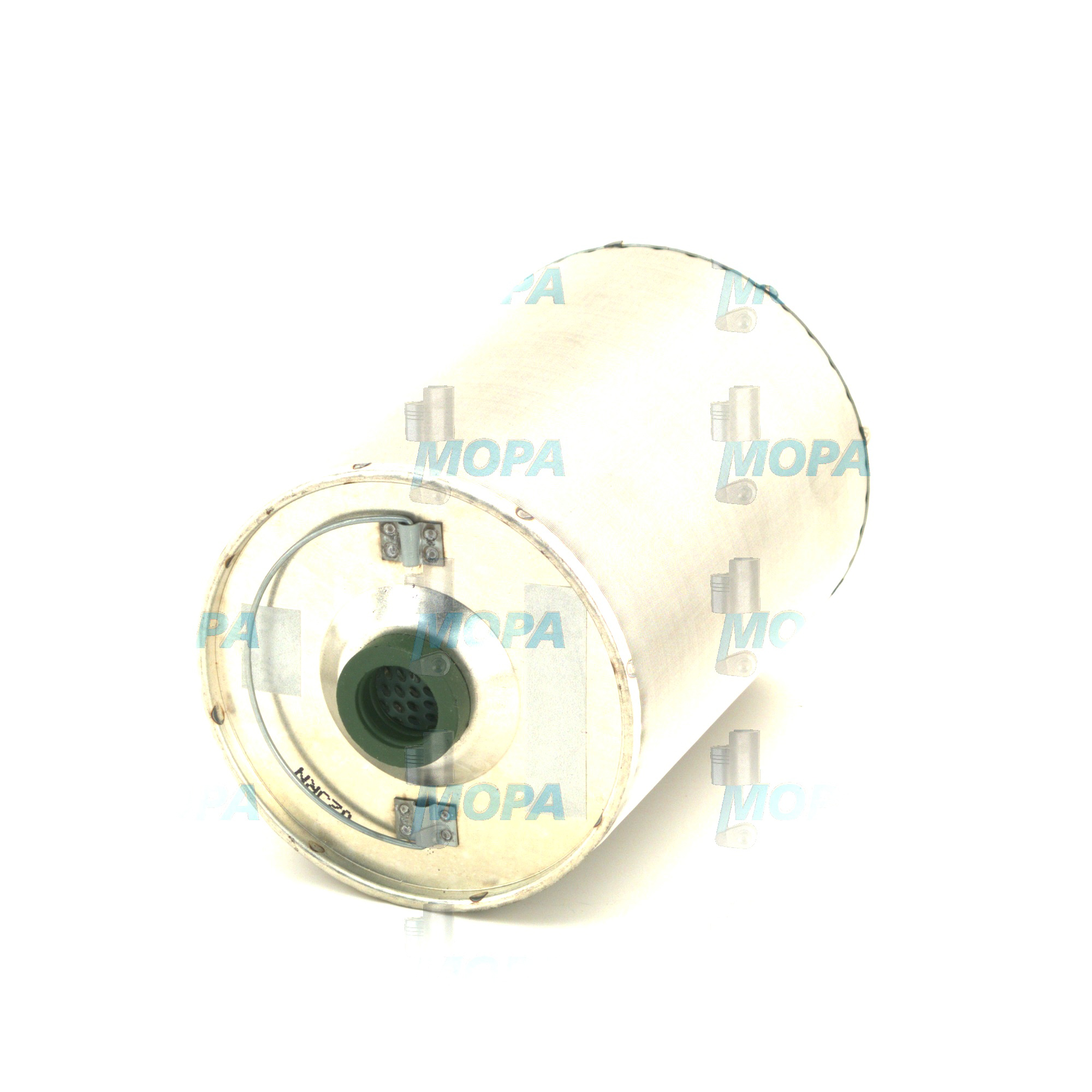

STRAINER ELEMENT Filter for Marine and Diesel Engines

Filters are critical components in every combustion engine, keeping fluids and intake air free from harmful contaminants. Within this category, the STRAINER ELEMENT serves as the first line of defense. It captures larger particles at high flow rates before finer filtration stages take over. In marine engine rooms and power plant installations alike, well-designed filters protect pumps, injectors, bearings, heat exchangers, and sensors—directly influencing availability, fuel efficiency, and lifecycle cost. Selecting the right Filter configuration, including a properly sized STRAINER ELEMENT, is therefore central to safe and economical operation.

In practice, filters span several media types and placements: suction strainers in lube oil sumps, basket or Y-strainers in seawater intakes, duplex fuel filters on transfer lines, and high-efficiency elements on the pressure side. A STRAINER ELEMENT focuses on coarse retention in the low micron to millimeter range, providing stable flow with minimal pressure drop and preventing catastrophic ingress of debris.

Technical Function of Filter and STRAINER ELEMENT in Engine Systems

A Filter removes contaminants from process media—oil, fuel, coolant, or air—by forcing the medium through a defined porous structure. The STRAINER ELEMENT is a specific type of filter element engineered for high-throughput, coarse filtration. Installed upstream of precision components, it blocks rust flakes, gasket remnants, scale, paint chips, or marine growth that could otherwise jam pumps and regulators.

STRAINER ELEMENT in a diesel engine lubrication circuit

On the suction side of a diesel engine lube oil pump, a STRAINER ELEMENT prevents large particles from entering the pump gears or rotors. This protects against scoring and loss of volumetric efficiency. Typical mesh sizes range from roughly 80 μm to 1,000 μm, with an open-area ratio optimized to minimize Δp at cold-start viscosities. By stabilizing inlet conditions, the strainer reduces cavitation risk and helps the downstream fine Filter maintain its Beta-ratio performance over longer intervals.

STRAINER ELEMENT in a marine engine seawater system

Marine engine cooling circuits rely on seawater strainers—often basket designs—for continuous protection of heat exchangers. A STRAINER ELEMENT in this application captures shells, algae, and corrosion products. Duplex housings enable online changeover for cleaning, avoiding downtime. Proper sizing considers flow (m³/h), debris load, and allowable pressure drop to preserve pump NPSH margins.

Fuel handling and transfer lines

Fuel transfer and day-tank lines frequently include a STRAINER ELEMENT ahead of duplex fine filters. This combination shields sensitive components like high-pressure pumps and injectors from fiber slough, tank scale, or sludge agglomerates. In consistent service, the strainer cuts the dirt burden on the fine Filter and extends service intervals.

When specified as STRAINER ELEMENT OEM parts, the geometry, mesh accuracy, and collapse strength align with the housing and service conditions defined by the engine maker. This precision ensures predictable pressure losses, reliable sealing, and straightforward maintenance in both diesel engine and marine engine environments.

- · High flow capacity with low pressure drop.

- · Robust mesh or perforated media for coarse retention.

- · Protects pumps, injectors, heat exchangers, and fine Filter stages.

- · Suction- and line-side installation options.

- · Duplex configurations for uninterrupted service.

- · Mesh sizes tailored to medium and operating conditions.

- · Easy inspection and cleaning, reduced maintenance time.

Why Filters and STRAINER ELEMENT Components Are Critical for Reliability

The health of an engine depends on clean fluids and intake air. If the Filter system is underspecified or the STRAINER ELEMENT is damaged or clogged, several issues can arise:

Abrasive wear accelerates on bearings and cylinder components when particles bypass filtration. Pumps experience cavitation and scoring if debris reaches the suction side. Clogged seawater strainers elevate cooling-water differential pressure, causing heat-exchanger fouling, rising jacket temperatures, and potential derating. In fuel systems, contaminants lead to injector nozzle erosion, poor atomization, increased soot, and higher specific fuel consumption. Even fine filters can fail prematurely if a missing or ineffective STRAINER ELEMENT overloads them with coarse debris.

Maintaining the specified Filter and STRAINER ELEMENT condition—correct mesh integrity, sealing, and seating—preserves stable flow, consistent pressure, and accurate system control. This translates to improved uptime, cleaner combustion, and longer service life for critical engine assemblies.

Advantages of OEM Spare Parts Suitable for Filter and STRAINER ELEMENT

Using OEM spare parts suitable for your Filter and STRAINER ELEMENT brings measurable benefits across performance, reliability, budget, and longevity:

Precisely manufactured meshes and endcaps ensure proper fit and sealing within the original housing, eliminating bypass pathways that would compromise filtration efficiency. Media and support structures are validated for collapse strength, thermal stability, and chemical compatibility with lube oils, fuels, coolants, or seawater. Consistent performance data helps maintenance teams plan service intervals with confidence, preventing unplanned stoppages.

From a cost perspective, correctly matched OEM spare parts stabilize differential pressure and reduce energy losses over the element’s life. They also minimize downstream wear and the frequency of fine Filter replacements. For fleet operators, the repeatability of OEM parts simplifies inventory, documentation, and crew procedures, improving maintenance consistency across vessels and sites.

MOPA: Your Partner for OEM Spare Parts Filter and STRAINER ELEMENT

MOPA supports purchasers, shipowners, and technical decision-makers with fast, dependable access to OEM spare parts for Filter systems and every STRAINER ELEMENT variant used on diesel and gas engines. Our team understands the fluid dynamics, materials, and approvals required in marine and power applications and sources to those specifications with speed and accuracy.

We emphasize short lead times, consistent quality, and secure handling from inquiry to delivery. Whether you need a suction STRAINER ELEMENT for a diesel engine sump, a duplex seawater strainer basket for a marine engine, or a complete Filter assembly with OEM parts, MOPA provides clear documentation, traceability, and technical support to keep your equipment running.

Conclusion: Filter and STRAINER ELEMENT for Dependable Engines

Filters—together with a correctly specified STRAINER ELEMENT—are essential to protect pumps, fuel systems, and heat exchangers, directly influencing engine performance and service life. Choosing OEM spare parts suitable for your Filter setup secures stable flow, predictable efficiency, and reduced lifecycle cost. With MOPA, you gain a responsive partner focused on speed, quality, and security in the trade of OEM parts for diesel and gas engines.