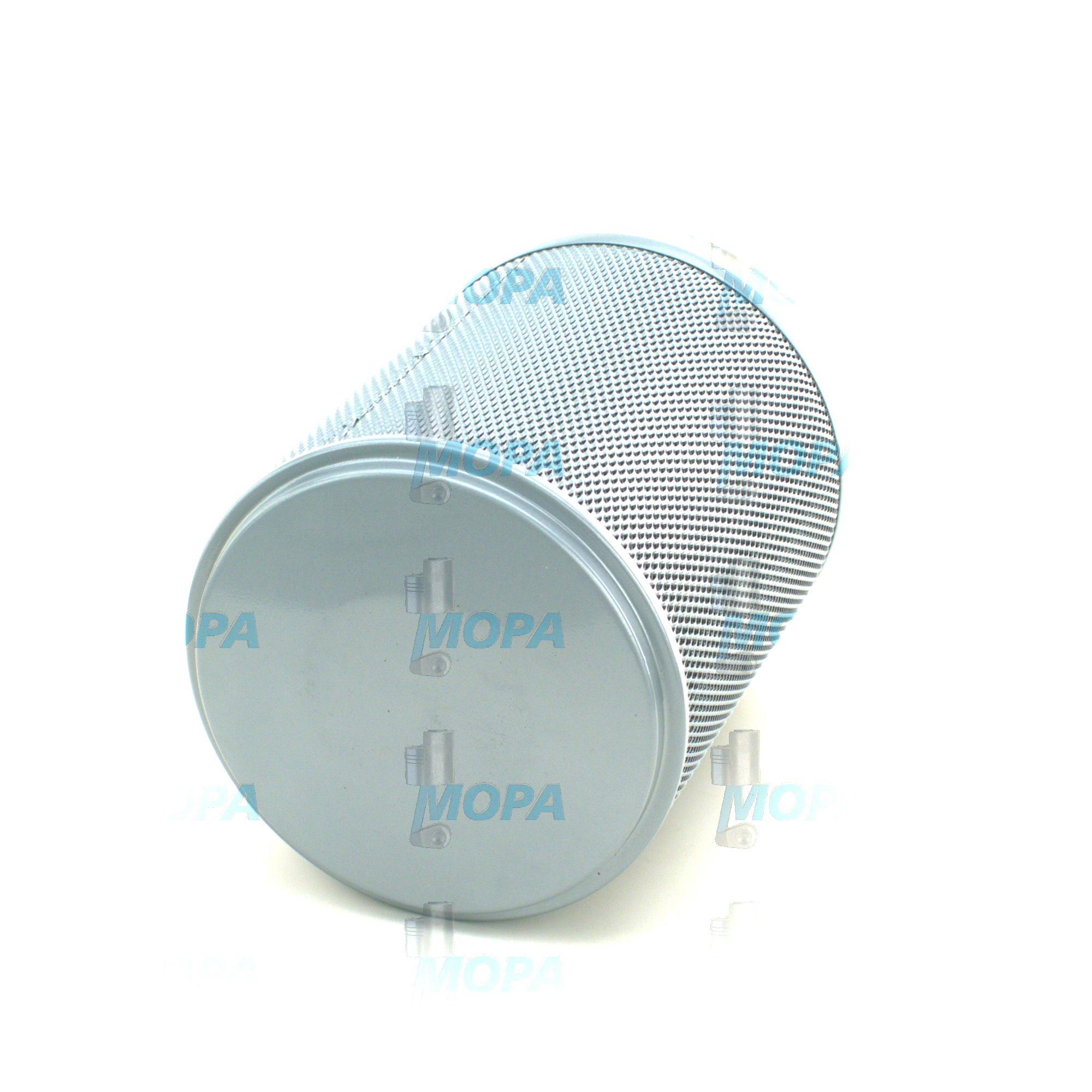

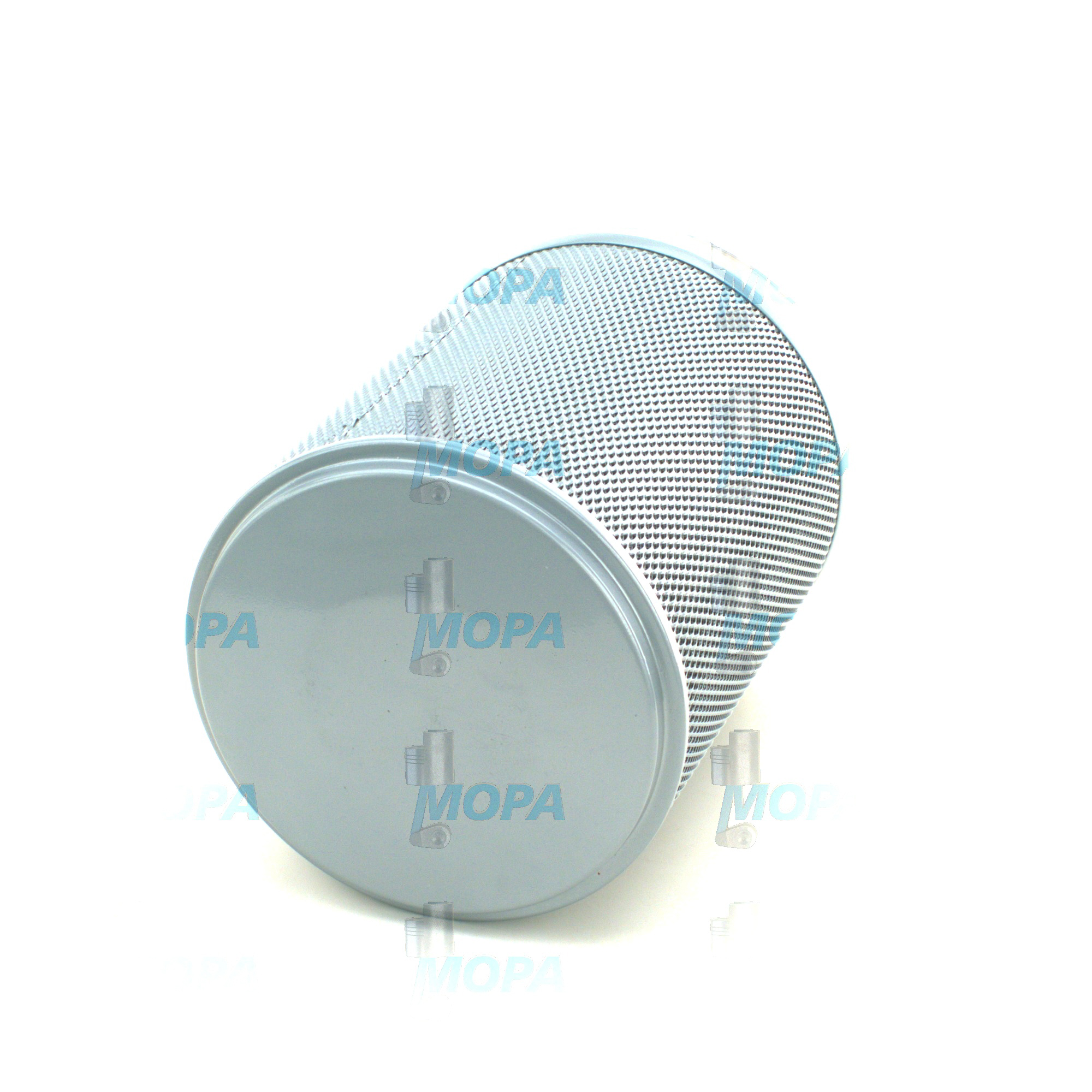

WET AIR CLEANER Filter – Intake Protection for Marine and Diesel Engines

A Filter is a fundamental engine component that separates contaminants from media such as air, fuel, lubricants, or coolant. Within the combustion air path, the WET AIR CLEANER filter protects cylinders, turbochargers, and valves from abrasive dust and salt-laden particles. By keeping intake air clean and consistent, it safeguards performance and extends the service life of marine engine and diesel engine platforms operating in ports, offshore conditions, and power generation environments.

Unlike dry elements, a WET AIR CLEANER relies on an oil-wetted medium or oil bath to trap particulates. This design is valued in harsh environments where high dust loads, moisture, and variable airflows challenge filtration stability. For shipowners and technical decision-makers, a properly selected and maintained WET AIR CLEANER filter reduces unplanned downtime, stabilizes fuel consumption, and lowers the risk of accelerated wear in critical engine internals.

Technical function of the WET AIR CLEANER Filter in a marine or diesel engine

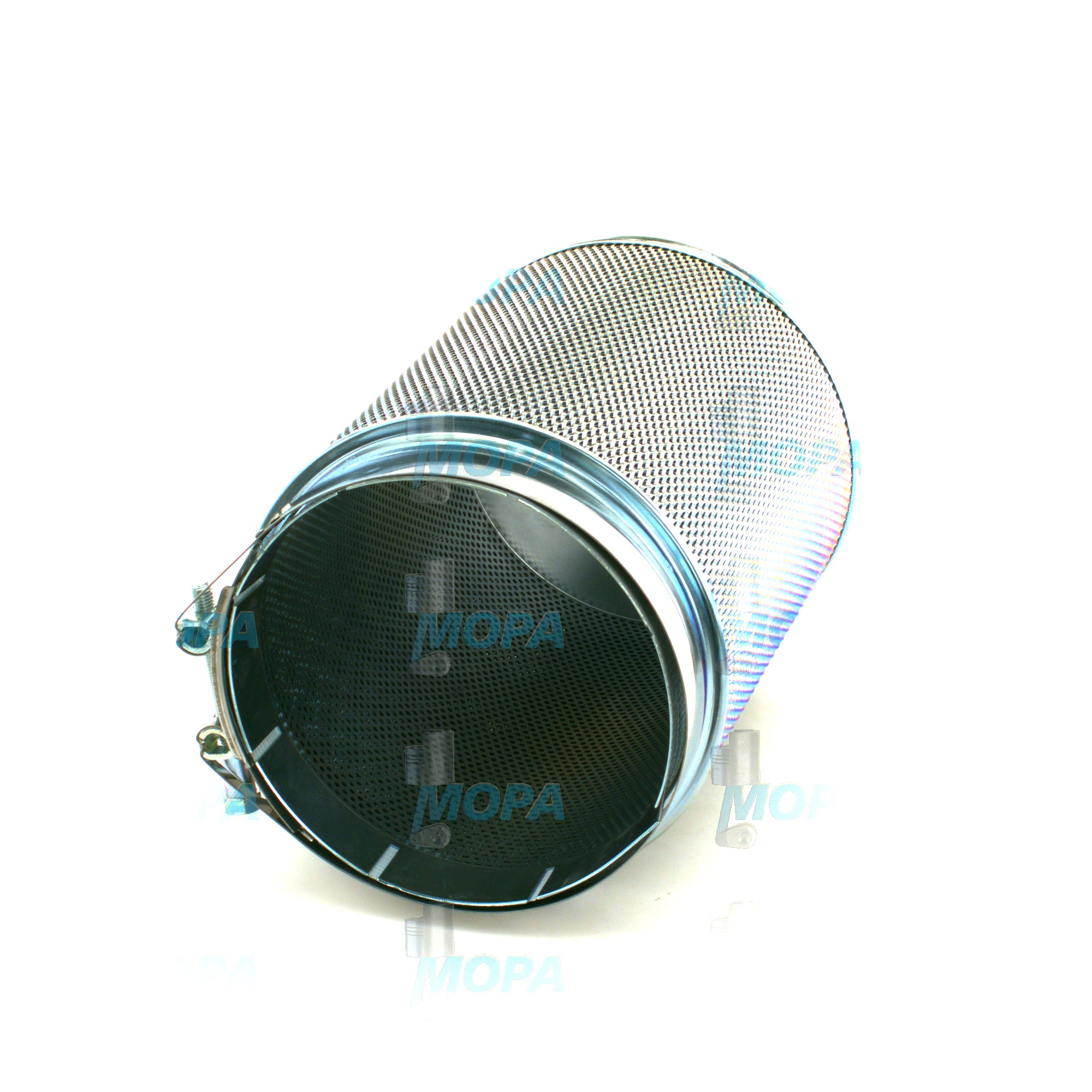

Air enters the WET AIR CLEANER housing and is directed over a wetted mesh or through an oil bath. Heavier particles lose momentum, impact the wetted surfaces, and become encapsulated in the oil film; gravity drives them into the sump where contaminants settle. Finer dust adheres to the oily fibers of the mesh pack. The result is highly efficient separation at low to moderate face velocity with stable pressure drop over long service intervals.

In a diesel engine, low restriction at the intake is essential for proper scavenging, turbocharger efficiency, and controlled combustion. The WET AIR CLEANER minimizes intake pressure losses when serviced correctly, maintaining airflow needed for rated power without overloading the turbocharger. In a marine engine exposed to spray and salt, the oil film also helps capture hygroscopic particles and mitigates corrosion risk downstream. When configured with flame-arresting elements for gas engines, the same assembly can offer an additional safety layer in the intake path.

To support predictable operation, many WET AIR CLEANER OEM parts include drain plugs for sludge removal, sight gauges for oil level checks, and provisions for differential pressure indicators. Routine service—cleaning the mesh pack, renewing the oil to the marked level, inspecting gaskets, and validating the restriction indicator—keeps the system within the designed pressure drop window and preserves filtration efficiency.

Key characteristics and advantages of Filter:

· High dust holding capacity for harsh marine and industrial environments.

· Stable pressure drop when serviced at proper intervals.

· Effective capture of fine and coarse particulates via oil-wetted media.

· Robust housings and seals suited to vibration and temperature cycles.

· Helps protect turbochargers, liners, rings, and valves from abrasive wear.

· Serviceable design with reusable mesh and replenishable oil bath.

· Configurable with indicators and drain points to simplify maintenance.

· Compatible with WET AIR CLEANER OEM parts across diesel and gas applications.

Why the WET AIR CLEANER Filter is critical for engine reliability and service life

Clean intake air is the first line of defense against mechanical wear. Abrasive dust bypassing or leaking past a compromised filter accelerates cylinder liner polishing, ring and groove wear, and compressor wheel erosion. Over time this raises blow-by, oil consumption, and vibration, ultimately reducing compression and reliability. Conversely, an over-restricted intake from a clogged filter raises exhaust temperatures, increases smoke, and pushes the turbocharger operating point into less efficient regions—conditions that can drive fuel consumption and thermal stress.

On vessels and power plants where engines run for long periods at steady load, small deviations in air quality and restriction compound quickly. Maintaining the WET AIR CLEANER filter in correct condition protects power density, preserves emissions margins, and reduces the likelihood of unplanned overhauls or premature turbocharger servicing.

Advantages of OEM spare parts suitable for Filter and WET AIR CLEANER assemblies

Using OEM spare parts suitable for the Filter ensures that the geometry, media characteristics, and sealing interfaces match the engineered specification. The oil-wetted mesh composition, baffle spacing, and housing tolerances determine capture efficiency and permissible restriction—areas where small deviations can materially affect performance. With WET AIR CLEANER OEM parts, purchasers can count on documented materials, consistent fit, and validated performance under vibration, temperature, and salt-mist exposure typical of marine duty.

From a budget perspective, the correct mesh density and oil bath layout deliver longer service intervals and predictable maintenance windows. That translates into less downtime, fewer unscheduled stops for cleaning, and lower total cost per operating hour. For safety and compliance, traceable OEM parts support documentation needs and align with class and fleet maintenance procedures, improving audit readiness without compromising engine throughput.

MOPA – experienced partner for WET AIR CLEANER OEM parts

MOPA supplies OEM spare parts suitable for Filter and WET AIR CLEANER systems with the speed, quality, and security required in global engine operations. Our team understands the intake-side sensitivities of diesel and gas engines and delivers parts with verified fit and performance, backed by precise logistics and documentation. Whether you operate a coastal fleet or a land-based power unit, MOPA streamlines procurement, shortens lead times, and reduces risk through reliable sourcing, careful packaging, and transparent order tracking.

Conclusion

The WET AIR CLEANER filter is a vital intake component that safeguards engine internals, stabilizes turbocharger operation, and preserves fuel efficiency in marine and diesel service. Selecting OEM spare parts suitable for Filter and WET AIR CLEANER assemblies ensures consistent performance, dependable reliability, and a cost-effective maintenance strategy across the engine’s service life.