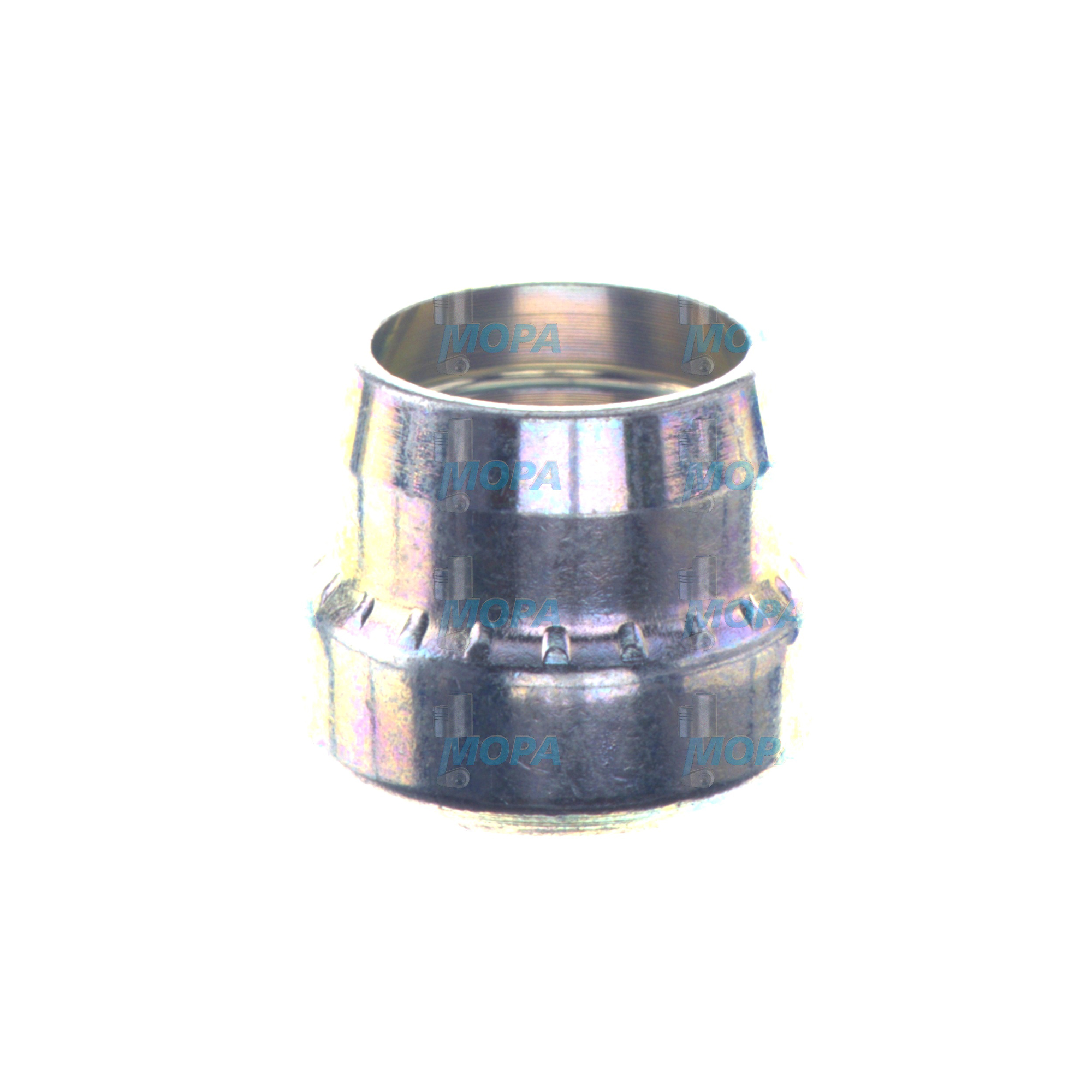

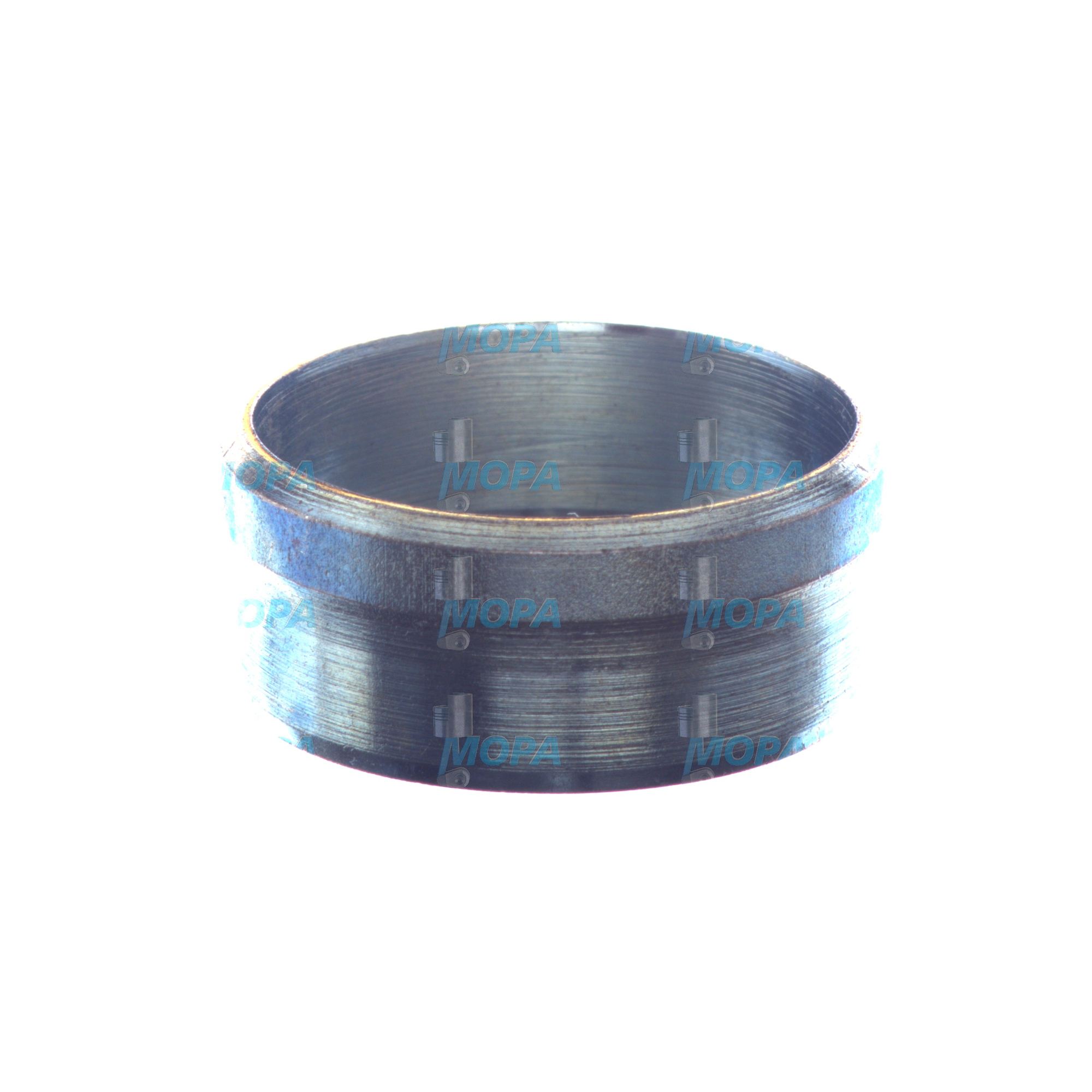

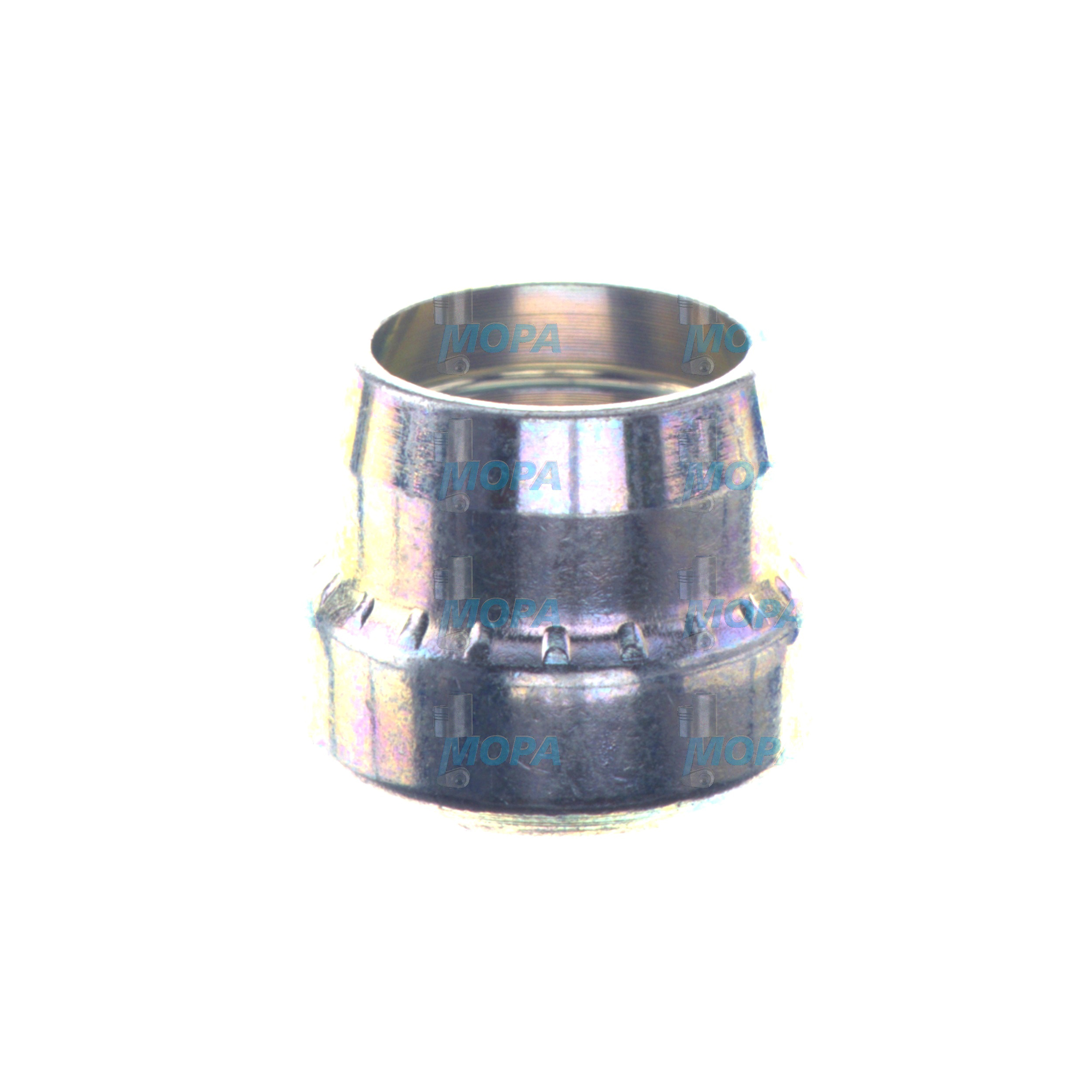

CUTTING RING Fittings and Armatures for High‑Performance Engines

Fittings and armatures are the precision components that connect, control, and secure every fluid path on a marine engine or diesel engine. This article category covers tube and hose fittings, compression connectors, valves, manifolds, and associated hardware that create leak-tight joints for fuel, lube oil, coolant, hydraulics, and compressed air. Within these assemblies, the CUTTING RING is a central sealing element widely used in industrial and maritime applications to achieve safe, repeatable, and serviceable connections under high pressure and vibration. Correctly selected and assembled fittings and armatures are critical to engine uptime, safety, and lifecycle cost.

Technical Function: How Fittings and Armatures with CUTTING RING Work in Marine and Diesel Engines

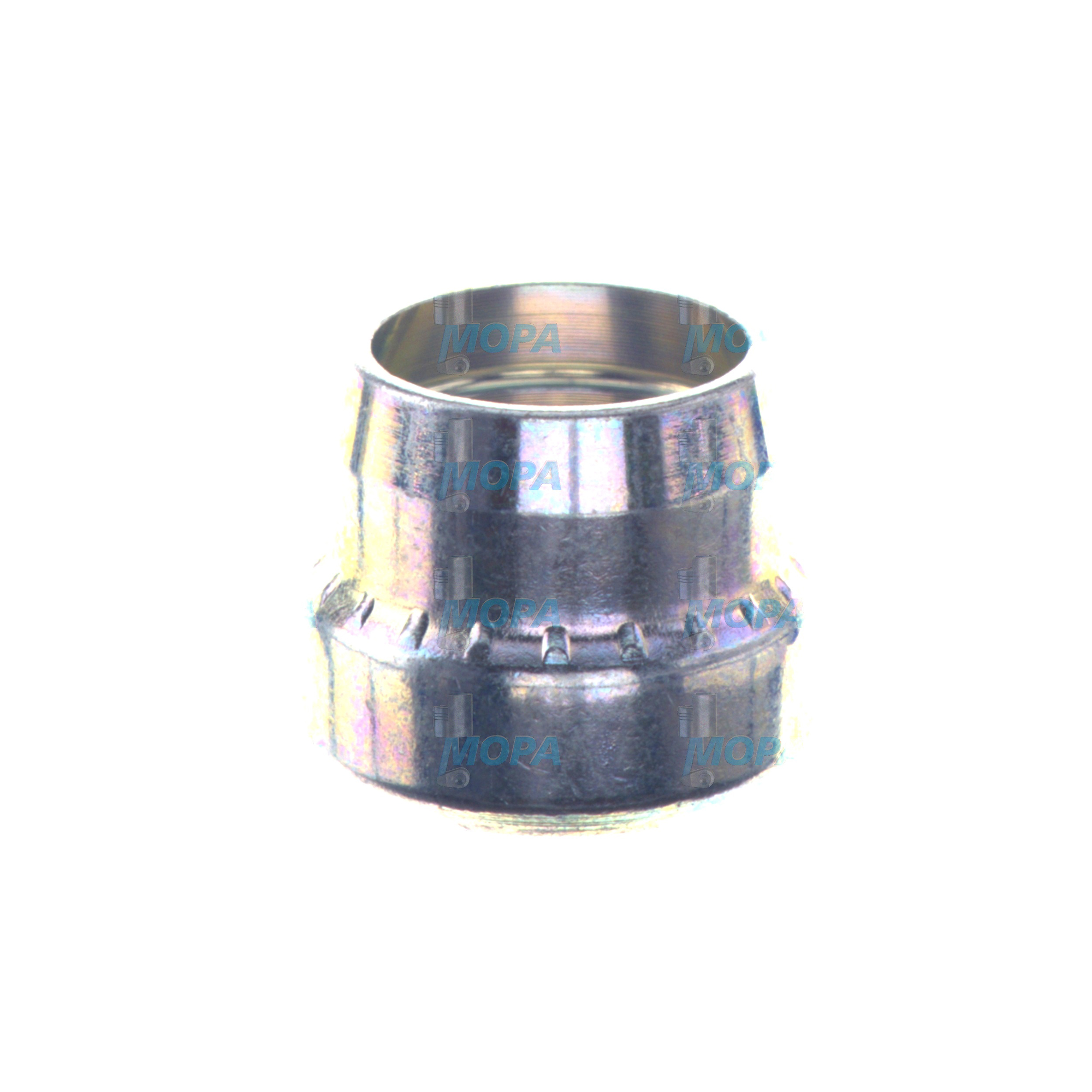

In engine rooms, fluid systems depend on reliable joints that withstand pressure cycling, pulsation, temperature shifts, and vibration. CUTTING RING technology—commonly specified in DIN/ISO compression fittings—uses a metallic ring that plastically deforms into the outer diameter of the tube during tightening. The ring “bites” into the tube and forms a robust, metal‑to‑metal seal while the fitting body and nut provide mechanical retention. This method delivers excellent resistance to loosening, making it ideal for fuel injection returns, hydraulic governor lines, oil mist separators, and coolant bypass circuits on a marine engine or diesel engine.

Modern fittings and armatures include straight, elbow, and tee bodies; nuts; tubes; and the CUTTING RING itself. Materials typically include carbon steel with zinc‑nickel coating for corrosion resistance, 316/316L stainless steel for aggressive environments, and selected copper alloys in low‑spark contexts. Thread forms span metric, BSPP/BSPT, and NPT, with sealing achieved via metal‑to‑metal contact or via elastomeric support seals when specified. Proper tube preparation (correct OD tolerance, roundness, deburring, and chamfering), controlled tightening torque, and verification of ring bite are essential to a reliable connection. The result is a joint that can be disassembled for service and reassembled with predictable sealing integrity—vital in confined engine-room maintenance windows.

When specified as CUTTING RING OEM parts, assemblies benefit from exact material grades, surface finishes, and dimensional tolerances aligned to the mating equipment. This ensures that flow coefficients, pressure ratings, and vibration resistance meet the designed envelope of the diesel engine and auxiliary systems.

- · Secure, leak‑tight sealing under pulsation and vibration

- · Repeatable assembly and serviceability in tight engine rooms

- · Broad material and size range for marine engine environments

- · Compatibility with metric, BSP, and NPT threads

- · High pressure capability for hydraulics and fuel systems

- · Corrosion‑resistant coatings and stainless steel options

- · Compliance with DIN 2353 / ISO 8434‑1 for CUTTING RING systems

Importance for Engine Operation: Reliability, Efficiency, and Safety

Fittings and armatures are small components with outsized impact. A single compromised connection can lead to fuel or oil leakage, air ingress, pressure loss, or contamination—all of which degrade engine performance and create safety risks. On a diesel engine, air entering a suction line can cause cavitation, injector misfiring, or pump damage. On a marine engine, leaking fuel presents fire risks and potential environmental incidents. In hydraulic control circuits, micro‑leaks increase energy losses, raise operating temperatures, and accelerate seal wear.

Using the correct CUTTING RING and mating components maintains the designed clamp load and seal geometry, resisting loosening from vibration and thermal cycling. Conversely, mis‑matched materials, off‑spec dimensions, or improper assembly torque can cause tube scoring, cold flow, thread galling, or stress cracking. Over time, these issues manifest as hard‑to-trace intermittent faults, unplanned stoppages, and higher maintenance costs. Properly engineered fittings and armatures preserve flow stability, maintain set pressures, and keep systems clean—directly supporting fuel efficiency and extending engine service life.

Advantages of OEM Spare Parts Suitable for Fittings and Armatures

For procurement and technical teams, selecting OEM spare parts suitable for this category delivers measurable benefits from commissioning through overhaul. CUTTING RING components and companion bodies built to the exact geometry of the equipment provide consistent bite depth, reliable reassembly, and stable torque‑tension relationships. This translates into predictable sealing performance across fuel, oil, cooling, and hydraulic circuits.

Key reasons to choose OEM spare parts suitable for Fittings and armatures:

- · Performance: Verified pressure/temperature ratings and flow characteristics.

- · Reliability: Tight tolerances ensure consistent CUTTING RING engagement.

- · Budget: Lower lifecycle cost through reduced leakage, rework, and downtime.

- · Service life: Superior materials and coatings resist corrosion and wear.

- · Compliance: Alignment with DIN/ISO standards and marine classification requirements.

- · Safety: Reduced risk of fuel and oil leaks in hot engine spaces.

By securing CUTTING RING OEM parts matched to the engine maker’s specifications, operators protect asset uptime while avoiding the hidden costs of reassembly failures, weeping joints, or premature corrosion.

CUTTING RING Details for Marine Engine and Diesel Engine Applications

In practice, technicians should confirm tube hardness and wall thickness compatibility per ISO 8434‑1, verify ring bite with inspection gauges, and observe retightening procedures after initial pressure cycling. Materials such as 1.4571/316Ti stainless steel offer superior pitting resistance in seawater-adjacent zones, while zinc‑nickel coated steel provides robust protection in standard engine rooms. Thread sealants, if specified, must be compatible with fuel and oil media and applied only to tapered threads, not to sealing faces on CUTTING RING compression joints. These details keep connections stable across long maintenance intervals and heavy operating profiles.

MOPA: Your Partner for OEM Parts in Fittings and Armatures

MOPA is an experienced, reliable partner for OEM spare parts in Fittings and armatures—including CUTTING RING components for diesel and gas engines. Customers value rapid sourcing, consistent quality, and transactional security across international supply routes. MOPA supports purchasers, shipowners, and technical decision‑makers with expert cross‑referencing, documentation, and on‑time delivery to minimize laytime and accelerate turnarounds. Whether the requirement is a single CUTTING RING for a critical leak fix or a complete bill of materials for a dry‑dock overhaul, MOPA ensures the right parts, at the right time, for marine engine and power‑plant applications.

Conclusion: CUTTING RING and Fittings and Armatures Matter

Fittings and armatures—anchored by proven CUTTING RING technology—are fundamental to safe, efficient, and reliable engine operation. Selecting OEM spare parts suitable for this category safeguards sealing integrity, reduces downtime, and extends service life.

With MOPA as a trusted partner for OEM parts, operators gain speed, quality, and security in procurement—keeping diesel and gas engines performing to specification in demanding marine environments.