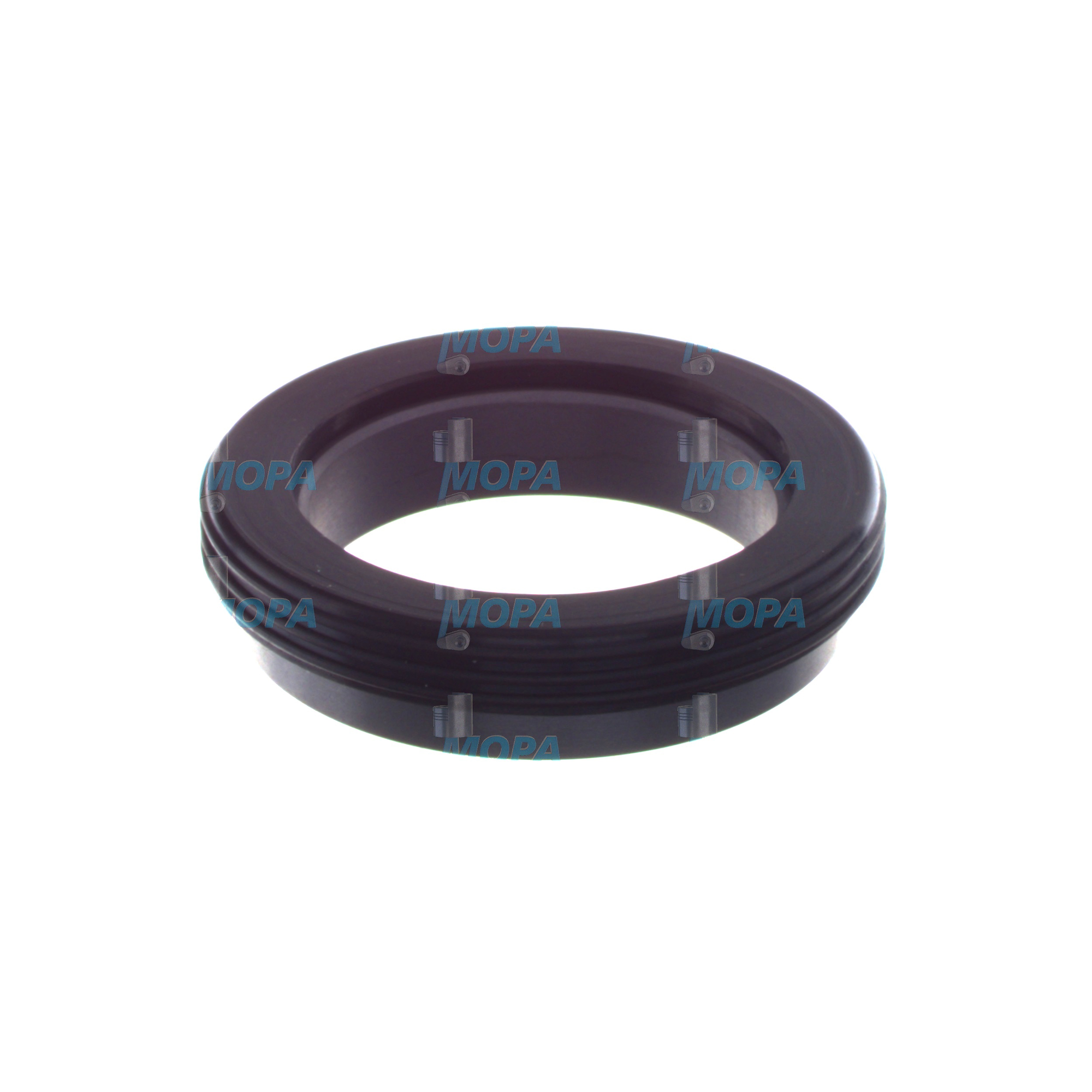

COUNTER RING and Gaskets for Marine and Diesel Engines

Gaskets are precision-engineered sealing elements that create reliable, pressure-tight joints between static components in engines and auxiliary systems. In marine and diesel engines, they sit between cylinder heads and blocks, exhaust manifolds and turbos, pumps and casings, fuel system flanges, and countless covers and housings. Their job is to prevent the escape or mixing of combustion gases, lubricants, fuel, and coolant, while accommodating thermal expansion and micro-movements. In many assemblies, gaskets interface with other sealing hardware—such as a stationary COUNTER RING in a marine engine’s mechanical seal—forming a complete leakage barrier that protects performance, safety, and operating budgets.

Technical function of gaskets in engines and the link to the COUNTER RING

Engine gaskets create static seals by conforming to surface irregularities under bolt load. The sealing material (e.g., multi-layer steel, graphite, aramid fiber, PTFE, nitrile elastomers) compresses and recovers to maintain contact despite pressure pulsations, temperature cycles, and vibration. Cylinder head gaskets maintain combustion pressure, isolate oil and coolant galleries, and resist hot gas attack at fire rings. Exhaust and turbo gaskets handle high temperatures and prevent gas leakage that would otherwise erode turbine efficiency. Oil pan and front cover gaskets stop lubricant loss, preserving oil pressure and bearing life.

In rotating equipment attached to the engine—circulation pumps, gearboxes, and shaft seals—gaskets and O-rings provide the static boundary, while a COUNTER RING diesel engine assembly delivers the dynamic face for the rotating seal. The COUNTER RING provides a flat, hard-wearing surface against which the rotating seal face runs. When paired correctly with the surrounding gasket arrangement, this stack-up delivers low leakage, low friction, and long service intervals. Specifying COUNTER RING OEM parts alongside the correct gasket materials ensures the whole sealing system works as designed.

- · High-temperature stability in exhaust and turbo interfaces.

- · Chemical resistance to fuel, coolant, and lubricant.

- · Controlled compressibility and elastic recovery.

- · Tight thickness tolerances for accurate clamping loads.

- · MLS, graphite, and fiber options for diverse duty cycles.

- · Reduced blow-by, oil loss, and coolant ingress.

- · Compatible with COUNTER RING marine engine seal assemblies.

- · Designed for easy handling and repeatable installation.

Importance of gaskets for engine reliability and service life

Reliable sealing is fundamental to the health and efficiency of any engine. If a head gasket loses clamp load or suffers creep relaxation, combustion gases can blow by into the cooling jacket, causing overheating, detonation, power loss, and elevated emissions. Micro-leaks at fuel system or intake joints disrupt air–fuel ratios and lower turbocharger effectiveness. Oil leaks reduce system pressure, accelerate bearing wear, contaminate bilges, and increase consumption. Coolant ingress into the oil circuit strips lubricant film strength and risks catastrophic failure.

Even small deviations—like incorrect gasket thickness or bead geometry—shift joint compression, leading to uneven stress distribution and early leaks. Surface finish and flatness of mating parts, torque sequence, and retightening intervals are equally decisive. In assemblies with a COUNTER RING (e.g., pump mechanical seals), a compromised gasket can misalign the seal faces, generate heat, and score the COUNTER RING marine engine surface, shortening service life and increasing unplanned downtime. Robust gasket selection and proper installation directly translate into better availability, predictable maintenance windows, and safer operation at sea.

Advantages of OEM spare parts suitable for gaskets

Choosing OEM spare parts suitable for gaskets ensures the sealing system matches the engine maker’s material specifications, bead profiles, and thickness tolerances. That precision preserves clamp load, controls micro-movements, and maintains the designed compression on sealing beads and fire rings. Correct materials resist thermal oxidation and chemical attack, which protects joint integrity across long duty cycles in diesel and gas engines.

From a budget and lifecycle perspective, the right OEM spare parts minimize leakage-related losses (fuel, lube oil, charge air), reduce cleanup and environmental exposure, and prevent secondary damage to turbos, bearings, and liners. When gaskets are paired with matching COUNTER RING OEM parts in shaft seal assemblies, face flatness, hardness, and surface finish are harmonized, reducing friction and wear. The result is stable efficiency, fewer deviations during class inspections, and shorter time in dock.

OEM gaskets and COUNTER RING synergy for performance

Sealing performance is system performance. An accurately manufactured gasket maintains bolt preload and isolates media; a correctly specified COUNTER RING diesel engine component keeps dynamic sealing faces stable. Together, these parts uphold pressure boundaries, preserve combustion quality, and protect auxiliaries—key drivers of fuel efficiency, emissions compliance, and long component life.

MOPA as your partner for OEM spare parts gaskets

MOPA supplies OEM spare parts suitable for gaskets and associated sealing components for diesel and gas engines with speed and technical certainty. Our team understands the interface between static gaskets, O-rings, and COUNTER RING assemblies, helping you source precisely matched components from trusted manufacturers. We focus on rapid availability, consistent quality, and traceable documentation, so purchasers and shipowners can plan maintenance with confidence and keep vessels on schedule.

Whether you operate main propulsion, auxiliary gensets, or critical pumps, MOPA streamlines procurement, mitigates risk in the supply chain, and supports you with knowledgeable application advice—from material selection to installation best practices.

Conclusion

Gaskets are essential to sealing integrity in marine and diesel engines, safeguarding performance, efficiency, and safety across every operating hour. Specify OEM spare parts suitable for gaskets—and align them with the correct COUNTER RING components—to achieve durable, leak-free joints, longer service intervals, and predictable maintenance costs.