CYLINDER HEAD GASKET and Gaskets for High-Performance Diesel and Marine Engines

Gaskets are precision-engineered sealing elements that ensure every fluid and gas inside an engine stays in its designated circuit. In heavy-duty diesel and gas engines—whether in power generation, rail, or a marine engine—this category includes everything from exhaust and intake gaskets to oil pan and cooling system seals. At the top of the list sits the CYLINDER HEAD GASKET, the critical interface between engine block and cylinder head. Together, these gaskets uphold compression, maintain lubrication and cooling integrity, and prevent cross-contamination that could compromise performance and safety. For purchasers, shipowners, and technical decision-makers, selecting the right gaskets is a strategic decision that directly influences uptime, total cost of ownership, and compliance with performance and emission targets.

Technical function: How Gaskets and the CYLINDER HEAD GASKET keep a diesel engine sealed

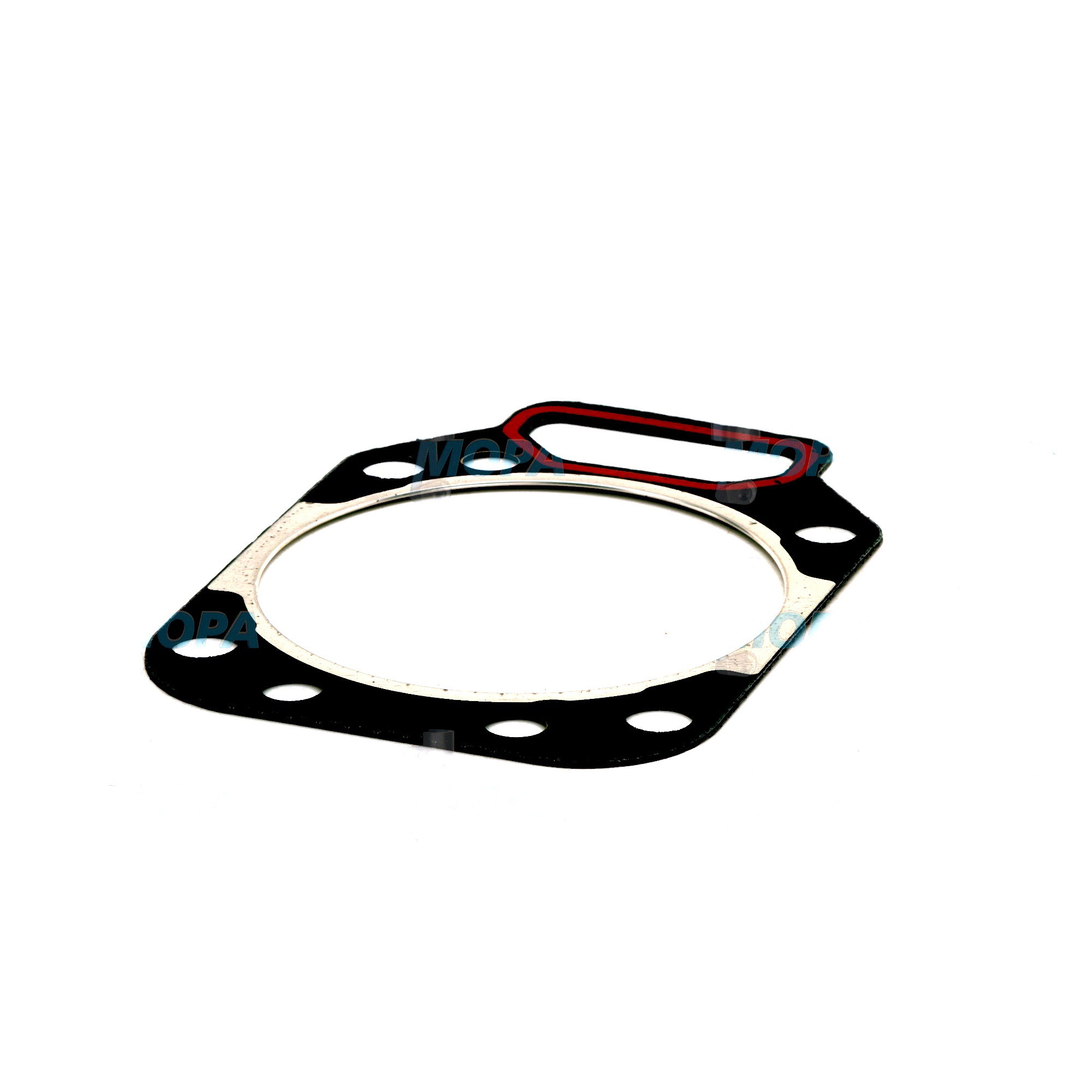

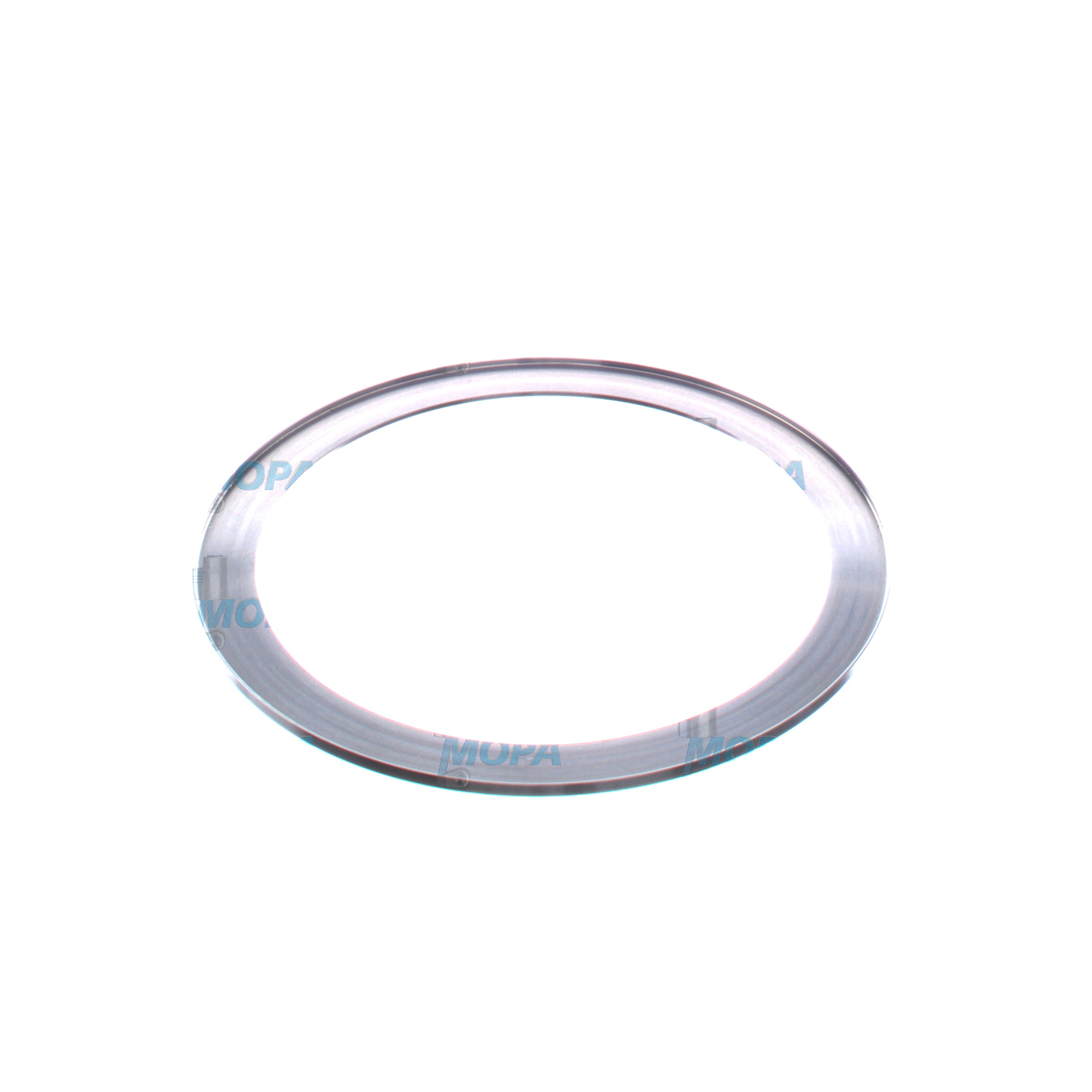

Every engine depends on stable sealing of combustion pressure, coolant, and lubricants under frequent thermal cycles and vibration. The CYLINDER HEAD GASKET in a diesel engine or marine engine must seal peak combustion pressures, isolate oil and coolant galleries, and handle micro-movements between the head and block. Typical designs use multi-layer steel (MLS) with elastomeric coatings, graphite or fiber-metal laminates, and specialized fire rings or embossments around the bores. These features create controlled contact pressures that adapt to surface roughness and thermal expansion, ensuring gas-tight integrity at firing loads while resisting creep and fatigue.

Correct function also depends on precise clamping. Bolt preload, torque-angle procedures, and even the pattern used during tightening are engineered so that the CYLINDER HEAD GASKET distributes load evenly. Surface finish and flatness of the head and block decks, liner protrusion on large-bore engines, and the chemical compatibility of the gasket materials with modern coolants and lubricants all play decisive roles. When sourced as CYLINDER HEAD GASKET OEM parts, the gasket’s bore geometry, bead heights, and coating thickness are aligned to the engine family, ensuring reliable sealing margins across its full temperature and load range.

Design and material factors of CYLINDER HEAD GASKET OEM parts

MLS constructions offer resilience against thermal cycling; graphite layers withstand high temperature gradients; stainless or coated steel provides strength and corrosion resistance; and targeted sealing beads concentrate pressure around combustion and fluid passages. For engines running high cylinder pressures, the fire ring design and embossment layout are matched to the block’s stiffness and bolt spacing. In marine engine environments, where long duty cycles and variable loading are common, the CYLINDER HEAD GASKET must resist fretting and micro-leakage while maintaining clamp force over extended service intervals.

- · Gas-tight combustion sealing under high pressure.

- · Reliable separation of oil and coolant circuits.

- · Materials engineered for heat, vibration, and corrosion.

- · Precision fit to engine bore spacing and fluid passages.

- · Stable clamp load via optimized beads and fire rings.

- · Compatibility with modern coolants, oils, and fuels.

- · Consistent performance across thermal cycles.

- · Reduced risk of blow-by, emulsification, and hot spots.

Importance for engine operation: Why Gaskets determine reliability and service life

When gaskets are not in correct condition, an engine’s reliability deteriorates rapidly. A fatigued CYLINDER HEAD GASKET can cause loss of compression, coolant ingress into cylinders, oil contamination, and localized overheating. Symptoms range from white exhaust and pressurized cooling systems to misfires and elevated crankcase pressures. Over time, corrosion accelerates inside water jackets, bearings are starved by diluted oil, and combustion stability declines—reducing efficiency and increasing emissions. On a marine engine, a leaking exhaust or turbo mounting gasket can elevate exhaust temperatures, stress the turbocharger, and raise the risk profile in the engine room. Conversely, a healthy gasket set preserves thermal balance, protects critical surfaces, and supports consistent power delivery.

Advantages of OEM spare parts suitable for Gaskets and the CYLINDER HEAD GASKET

OEM spare parts suitable for Gaskets are engineered to the exact geometry, materials, and surface treatments intended by the engine designer. For the CYLINDER HEAD GASKET, this precision translates into correct bore sealing, optimized bead height and hardness, and coatings that bond properly to head and block surfaces. The outcome is sustained compression, stable operating temperatures, and minimal fluid consumption.

For operators managing budget and uptime, consistent fit and performance reduce installation time, rework, and unplanned stoppages. Fleet standardization becomes practical: a known specification for a diesel engine family prevents variability that could alter clamp load or surface stress. In addition, OEM spare parts are validated to coexist with the engine’s thermal expansion behavior, liner protrusion targets, bolt stretch values, and coolant chemistry—factors that protect components and extend service life.

Best practices to maximize CYLINDER HEAD GASKET performance

Apply the specified torque-angle sequence, confirm fastener condition (especially torque-to-yield bolts where applicable), and verify deck flatness and surface roughness before installation. Check liner protrusion and shim selection on large-bore engines. Flush and refill with the recommended coolant and oil formulations to protect gasket coatings. After initial heat cycles, conduct scheduled inspections for pressure stability and fluid cleanliness. These practices, coupled with OEM spare parts suitable for gaskets, maintain sealing margins and promote durable, predictable operation.

MOPA as a partner for OEM spare parts Gaskets

MOPA is an experienced, reliable partner for sourcing OEM spare parts Gaskets, including the CYLINDER HEAD GASKET for diesel and gas engines. We prioritize speed in quotation and delivery, consistent product quality, and security in the trade of OEM parts—supporting documentation, batch traceability, and correct part-number matching. Whether you need a single CYLINDER HEAD GASKET for a genset overhaul or a coordinated gasket kit for a marine engine dry-dock, MOPA helps reduce lead times and procurement risk with knowledgeable support and a global supply network.

Conclusion: CYLINDER HEAD GASKET and Gaskets that protect performance

Gaskets—headed by the CYLINDER HEAD GASKET—are foundational to combustion sealing, fluid integrity, and the long-term reliability of diesel and marine engines. Selecting OEM spare parts suitable for gaskets safeguards performance, optimizes budget through fewer interventions, and supports the service life your operation depends on.