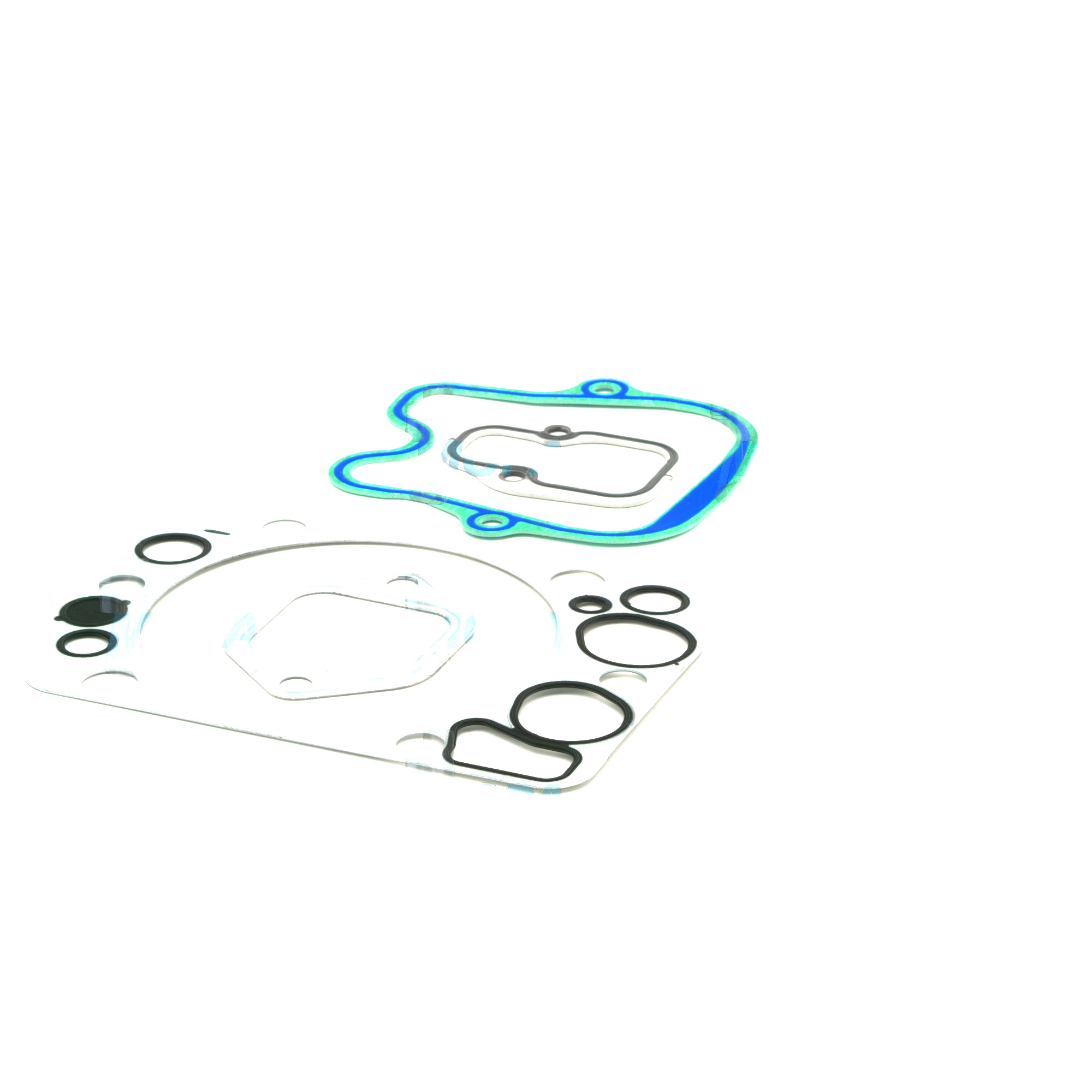

DECARBONIZER SET Gaskets for Marine and Diesel Engines

Gaskets are precision sealing elements used throughout engines to prevent the escape or cross-contamination of gases and fluids. In heavy-duty diesel and marine engines, they sit between mating surfaces—such as cylinder head and block, exhaust manifold and turbocharger, or pump housings and pipe flanges—to create a reliable, pressure-tight barrier. By maintaining compression, oil pressure, coolant circulation, and gas-tight exhaust paths, gaskets protect performance and keep vital systems stable. Whether you are preparing a major overhaul with a DECARBONIZER SET for a marine engine or planning routine service on a diesel power plant, selecting the correct gaskets is foundational to engine efficiency and uptime.

Within the article category Gaskets, you will find head gaskets (often multi-layer steel/MLS), metal-jacketed and graphite gaskets for high-temperature joints, spiral wound gaskets for flanged connections, elastomeric profile gaskets for covers and doors, and sealing washers for injectors and banjo bolts. Each design is engineered to accommodate surface roughness, thermal expansion, and bolt preload, ensuring stable sealing over thousands of operating hours.

Technical function of Gaskets in a diesel engine and marine engine

Gaskets work by conforming to micro-irregularities on mating surfaces and maintaining a controlled “crush” under bolt load. This creates a continuous barrier that resists pressure, temperature, vibration, and chemical attack. Head gaskets preserve combustion pressure and prevent oil-coolant cross-leakage; exhaust gaskets keep hot gases contained to protect turbocharger efficiency; charge-air cooler and intake gaskets prevent unmetered air leaks that would reduce power density; pump and cover gaskets maintain hydraulic integrity for lubrication and cooling circuits.

During decarbonizing work—such as cleaning exhaust ports, valves, and piston crowns with a DECARBONIZER SET diesel engine kit—disturbed joints must be reassembled with new, specification-matched gaskets. This ensures restored compression, correct emissions, and stable thermal behavior after carbon removal. Likewise, procurement of DECARBONIZER SET OEM parts often goes hand-in-hand with a complete gasket replacement package to secure every service interface touched during the overhaul.

Materials and designs aligned with DECARBONIZER SET OEM parts

Material selection is critical: MLS designs with elastomer beads maintain clamping force under cyclical firing loads; graphite and metal-reinforced gaskets withstand exhaust temperatures and flange movement; PTFE and aramid fiber composites resist oils and coolants; copper sealing rings for injectors provide crush and thermal conductivity. Correct thickness restores factory clearances and ensures that cam timing, compression ratio, and bearing crush are unaffected during rebuilds that include DECARBONIZER SET marine engine maintenance.

- · Gas- and liquid-tight sealing across varied temperature and pressure ranges.

- · Compensates for surface roughness and flange distortion.

- · Maintains bolt preload and resists relaxation and creep.

- · Materials tailored to media: fuel, lube oil, coolant, combustion gases.

- · Designs for high-temperature joints (exhaust/turbo) and dynamic covers.

- · Helps stabilize compression, emissions, and fuel efficiency.

- · Reduces risk of unplanned downtime from leaks and hot spots.

- · Matches DECARBONIZER SET service scopes for efficient overhauls.

Why Gaskets are critical for reliability and service life

In large-bore diesel and gas engines, gasket integrity directly influences availability and total cost of ownership. A compromised head gasket causes loss of compression, overheating, and potential coolant-oil contamination. Leaking exhaust gaskets lead to turbocharger performance loss, soot accumulation, and safety risks from hot gas egress. Failed charge-air gaskets reduce boost pressure and fuel economy. Oil-pan or cover leaks escalate into lubrication shortfalls and bearing distress.

Typical failure modes include thermal cycling fatigue, chemical degradation, creep relaxation, bolt preload loss, and fretting from vibration. Preventive measures are straightforward: observe specified surface finish (often 1.6–3.2 μm Ra for MLS contact faces), follow the maker’s torque/angle sequence with clean, lightly oiled threads where prescribed, and replace gaskets and sealing washers whenever joints are opened—especially during DECARBONIZER SET diesel engine service steps. Using the correct gasket thickness and material ensures clearances and thermal paths remain within design limits, extending service intervals and protecting core components.

Advantages of OEM spare parts suitable for Gaskets

For high-value assets, OEM spare parts suitable for gaskets deliver consistent sealing performance and predictable overhaul results. Dimensional accuracy, controlled compressibility, and validated compounds protect against premature relaxation and media attack. This alignment with the engine maker’s specifications safeguards performance, emissions stability, and fuel efficiency while controlling lifecycle costs.

With OEM-specification gaskets, procurement teams can expect traceable materials, stable lead times, and consistent fit. The result is fewer reworks, tighter emissions compliance, and reduced risk of undetected microleaks that undermine reliability. When paired with a DECARBONIZER SET OEM parts package during a scheduled outage, correctly matched gaskets shorten turnaround and help teams bring the unit back online with confidence.

MOPA: fast and secure supply of OEM parts for Gaskets and DECARBONIZER SET

MOPA is an experienced, reliable partner for OEM spare parts Gaskets, supporting operators of diesel and gas engines across marine, power, and industrial applications. We combine speed, quality, and security in the trade of OEM parts, delivering gasket kits aligned to DECARBONIZER SET diesel engine work scopes as well as single references for targeted repairs. Our team ensures technical clarity, correct materials, and precise dimensions, backed by robust logistics and documentation for smooth customs handling and class compliance where required.

Whether you need a complete cylinder head sealing package, exhaust manifold gaskets for a turbo retrofit, or tailored sets synchronized with a DECARBONIZER SET marine engine service, MOPA helps minimize downtime and safeguard engine integrity.

Conclusion: Gaskets and DECARBONIZER SET OEM parts for dependable engines

Gaskets are essential for maintaining compression, fluid integrity, and emissions performance in marine and diesel engines. Aligning gasket selection with DECARBONIZER SET OEM parts during overhauls restores sealing reliability, shortens outage times, and protects long-term engine service life.

MOPA supplies the right OEM spare parts suitable for Gaskets with speed and technical precision—so your assets return to service efficiently and operate with dependable performance.