FLOATING SEAL Gaskets for Marine and Diesel Engines

Gaskets are precision-engineered sealing elements that create tight, reliable barriers between static mating surfaces across an engine. In high-output marine engines and heavy-duty diesel engines, they prevent the mixing of fluids and gases, maintain compression, and protect sensitive components from thermal and mechanical stress. As an article category, Gaskets encompass head gaskets, exhaust and intake gaskets, turbocharger and aftercooler seals, oil pan and timing cover gaskets, and numerous specialized seals used in auxiliary systems. Their role is fundamental to uptime, safety, and overall engine efficiency.

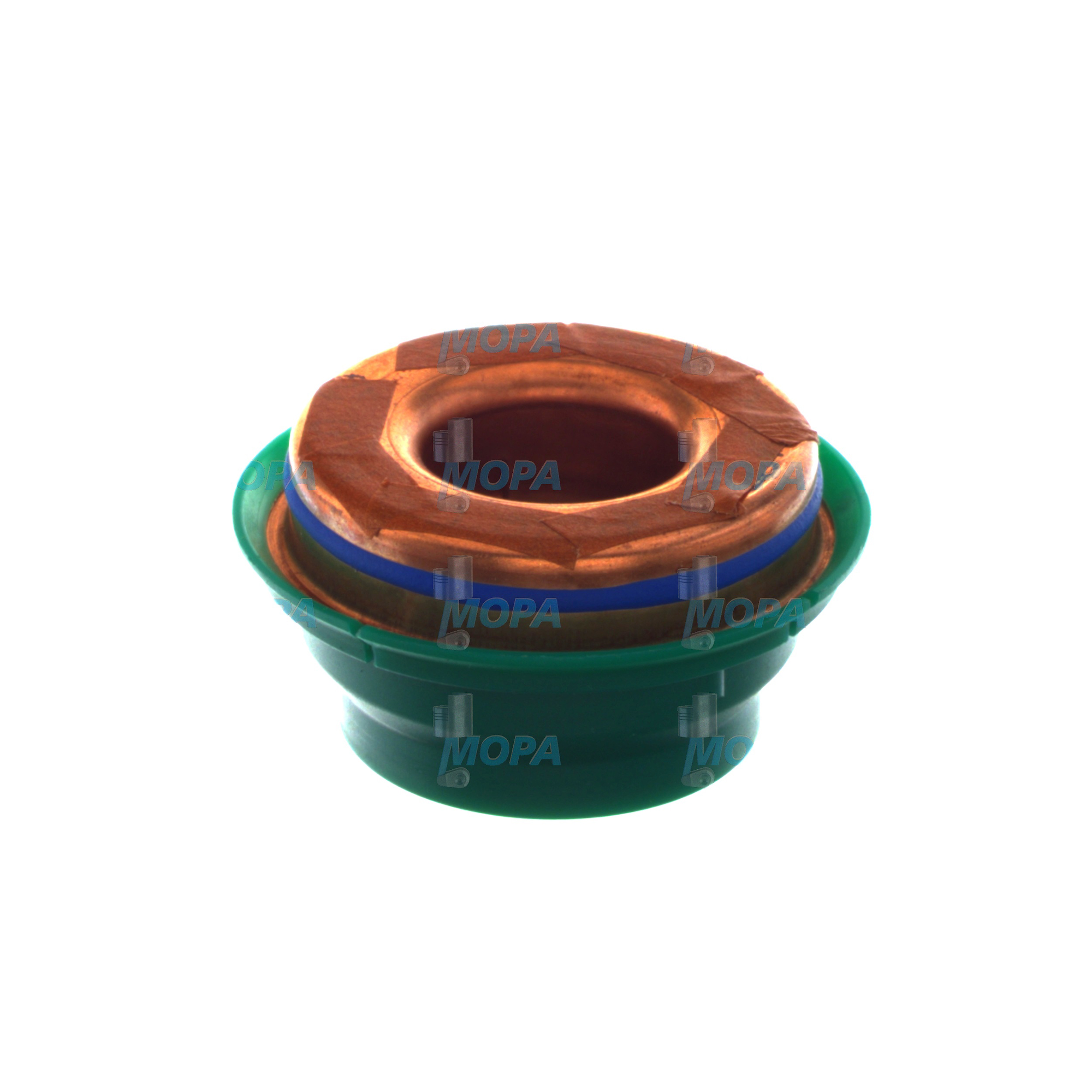

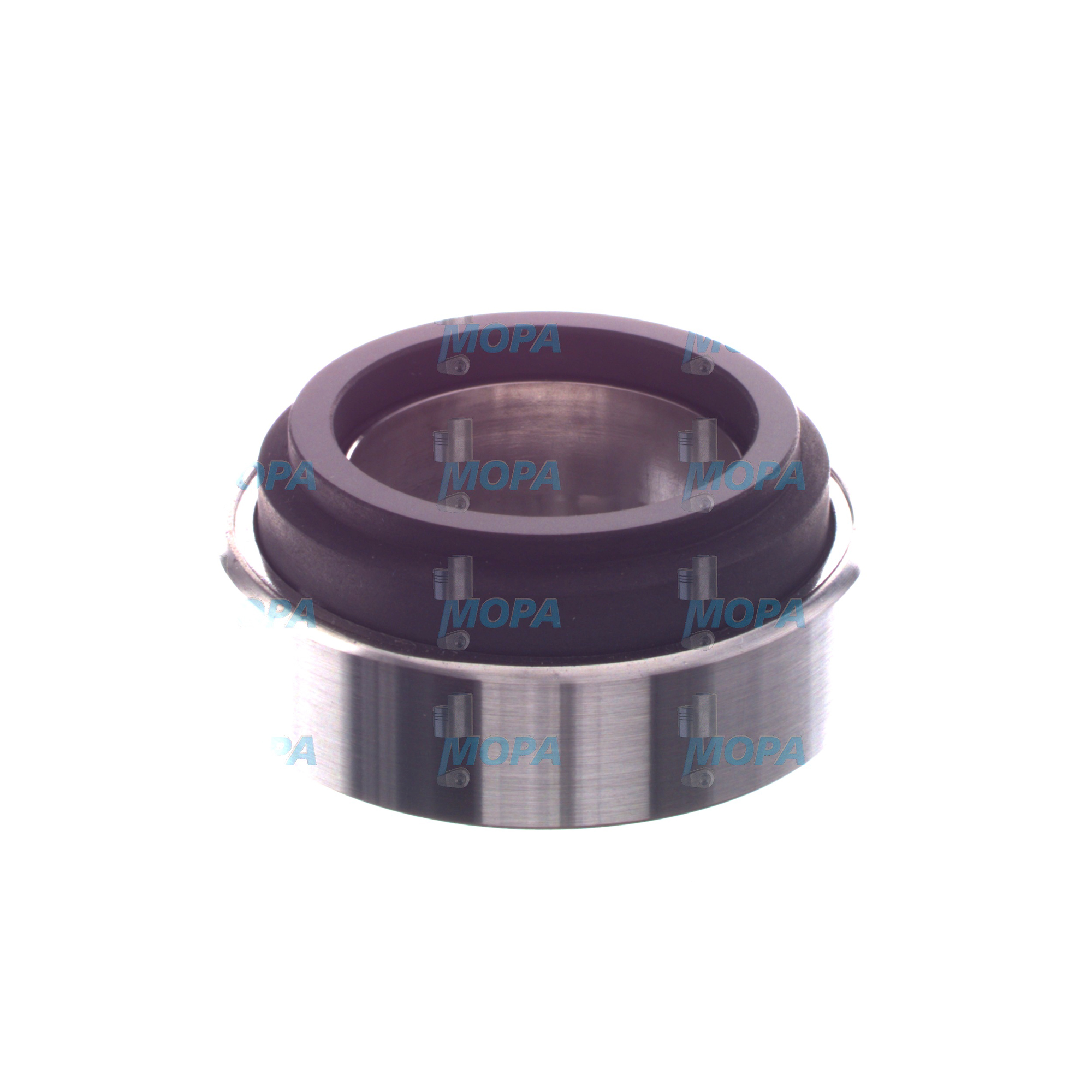

While the term FLOATING SEAL typically describes a mechanical face seal used in rotating assemblies, it often appears alongside gasket requirements in marine engine and diesel engine procurement. Both sealing technologies must work in harmony: where a FLOATING SEAL isolates a rotating interface, surrounding housings and covers rely on gaskets to keep fluids contained and pressures stable. For purchasers and technical decision-makers, understanding the wider sealing system ensures the right combination of gaskets and complementary components for durable performance.

Technical function of Gaskets and the role of FLOATING SEAL in marine and diesel engine assemblies

Gaskets deliver leak-free joints by conforming to micro-roughness on mating surfaces when clamped at the correct torque. In a diesel engine, the head gasket maintains combustion pressure while simultaneously sealing coolant and oil galleries. Exhaust and intake gaskets preserve gas flow and prevent ingress or escape that would reduce volumetric efficiency. On turbochargers and charge-air coolers, correctly specified gaskets sustain boost pressure and temperature cycling without creep or blowout.

Material selection is crucial: multi-layer steel (MLS) head gaskets handle high cylinder pressures and thermal expansion; graphite and spiral-wound gaskets resist extreme exhaust temperatures; elastomer-bonded and PTFE-based gaskets deliver chemical compatibility for fuels, oils, and coolants. Surface finish, flange flatness, bolt pattern, and torque sequence directly influence gasket compression set and long-term stability. In assemblies that also incorporate a FLOATING SEAL marine engine arrangement—for example, gear-driven auxiliaries—the adjacent static joints must be sealed by gaskets that tolerate vibration and thermal gradients without relaxation.

Using OEM parts for these joints ensures that material specifications, bead designs, fire rings, and coating chemistries match the engine platform’s validation data. In FLOATING SEAL diesel engine housings, correctly matched OEM parts gaskets maintain alignment and prevent cross-leaks that could undermine the face seal’s performance.

Key characteristics and advantages of Gaskets:

· High-temperature stability for sustained load and thermal cycling.

· Chemical resistance to fuel, oil, coolant, and exhaust condensates.

· Precise thickness and compressibility for accurate joint preload.

· Blowout resistance under pulsating pressure and vibration.

· Controlled creep/relaxation for long service intervals.

· Low-emission sealing at manifold and EGR interfaces.

· Corrosion control via coatings and carrier materials.

· Compatibility with OEM parts torque specs and surface finishes.

Why Gaskets are critical for engine reliability and service life

Engine reliability depends on stable sealing over thousands of operating hours. A compromised head gasket causes compression loss, combustion gas “blow-by,” coolant ingress into oil, or oil contamination of coolant—each scenario accelerates wear, drives up friction losses, and can lead to catastrophic failure. Exhaust gasket leaks elevate backpressure, impair turbocharger efficiency, and increase EGTs, risking turbine damage. Intake or charge-air leaks reduce boost, degrade fuel economy, and disturb emissions control strategies. Coolant gasket failures introduce aeration and cavitation, eroding pump components and liners.

In a marine engine, leakage can contaminate bilges, trigger safety incidents, or cause unplanned stops—particularly damaging for vessels working tight schedules. On diesel generator sets, gasket failures translate directly into downtime, emergency repairs, and elevated lifecycle costs. Maintaining the sealing integrity of every static joint preserves performance, keeps fluids where they belong, and safeguards the service life of critical rotating components, including assemblies where a FLOATING SEAL OEM parts interface is present.

Advantages of OEM spare parts suitable for Gaskets and FLOATING SEAL interfaces

Opting for OEM spare parts suitable for gaskets provides repeatable fit, consistent clamping behavior, and validated materials. Dimensional accuracy ensures correct fire ring seating, uniform bead compression, and proper alignment of fluid passages. Coatings and carrier metals are formulated to handle the thermal envelope of specific engine families, from high-output diesel engine platforms to gas engine applications.

The result is predictable assembly torque, reduced rework during overhauls, and stable sealing performance that protects adjacent components such as turbochargers, pumps, and FLOATING SEAL housings. By maintaining designed clearances and pressures, OEM spare parts help sustain power density, fuel efficiency, and emissions conformity—critical metrics for fleet operators and shipowners focused on total cost of ownership.

From a budgeting perspective, the right OEM specification avoids premature gasket relaxation, blowout, or chemical degradation that would lead to repeat interventions. In short, suitable OEM spare parts for gaskets are a direct investment in uptime, reliability, and the overall lifecycle of marine and industrial engines.

MOPA – experienced partner for OEM Gaskets and FLOATING SEAL related components

MOPA is a reliable partner for OEM spare parts Gaskets, supporting diesel and gas engines across marine and industrial sectors. Customers value MOPA for speed in sourcing, consistent quality, and security in the trade of OEM parts. With application know-how spanning cylinder heads, manifolds, turbocharger interfaces, and auxiliary housings that may include a FLOATING SEAL marine engine arrangement, MOPA helps you specify the exact gasket set needed for a precise, leak-free overhaul.

Traceable sourcing, robust logistics, and careful packaging protect sensitive sealing surfaces. Technical support covers torque procedures, surface finish guidance, and installation best practices, helping your teams complete maintenance on schedule and return assets to service with confidence.

Conclusion: Gaskets that support performance alongside FLOATING SEAL applications

Gaskets are foundational to engine performance, efficiency, and safety, ensuring stable sealing across combustion, lubrication, cooling, and gas-exchange systems. Specifying OEM spare parts suitable for Gaskets—and aligning them with FLOATING SEAL diesel engine or marine engine assemblies—delivers reliable uptime, consistent power, and long service life.

Partnering with MOPA streamlines procurement for OEM parts, protects your budget through dependable service intervals, and keeps fleets operating at their best.