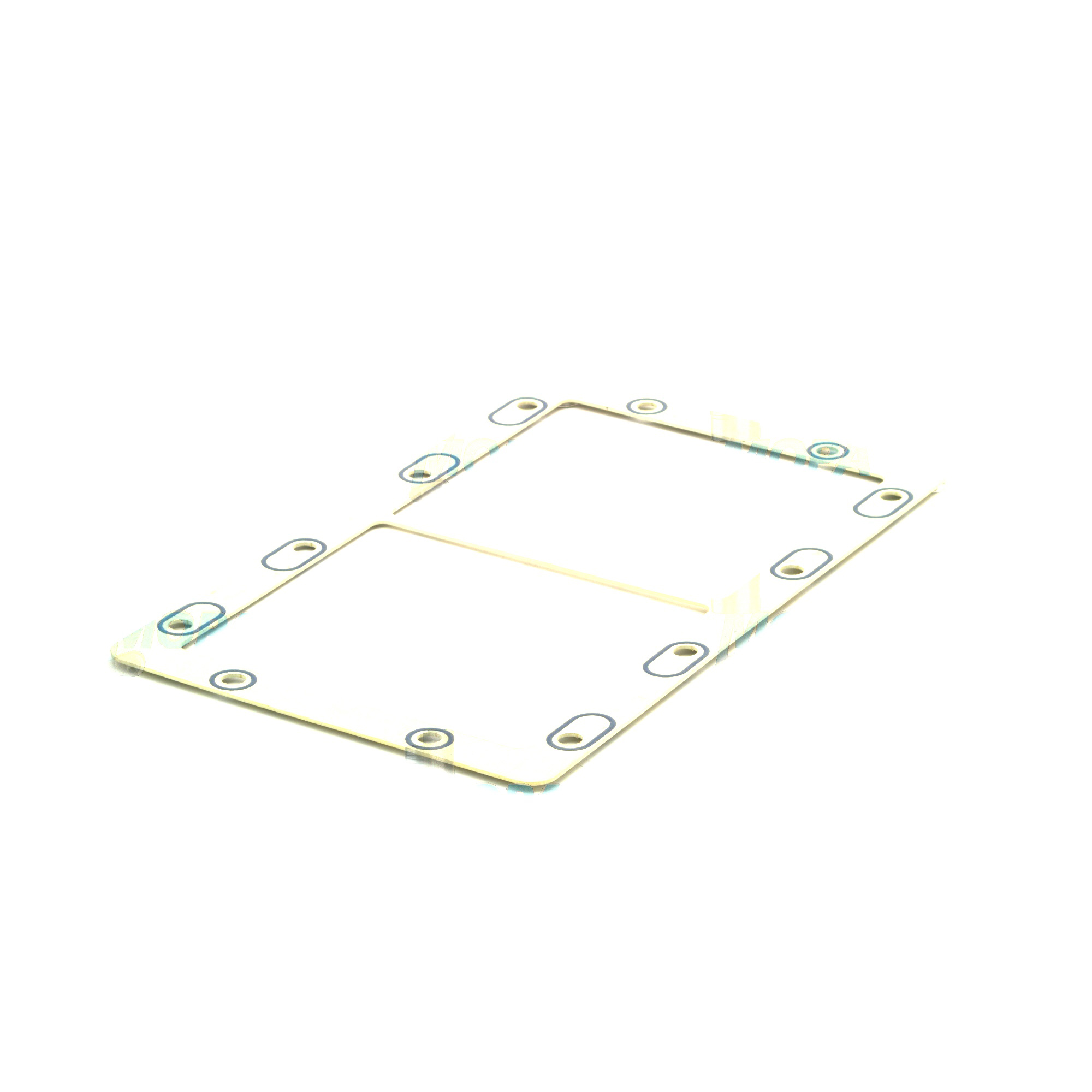

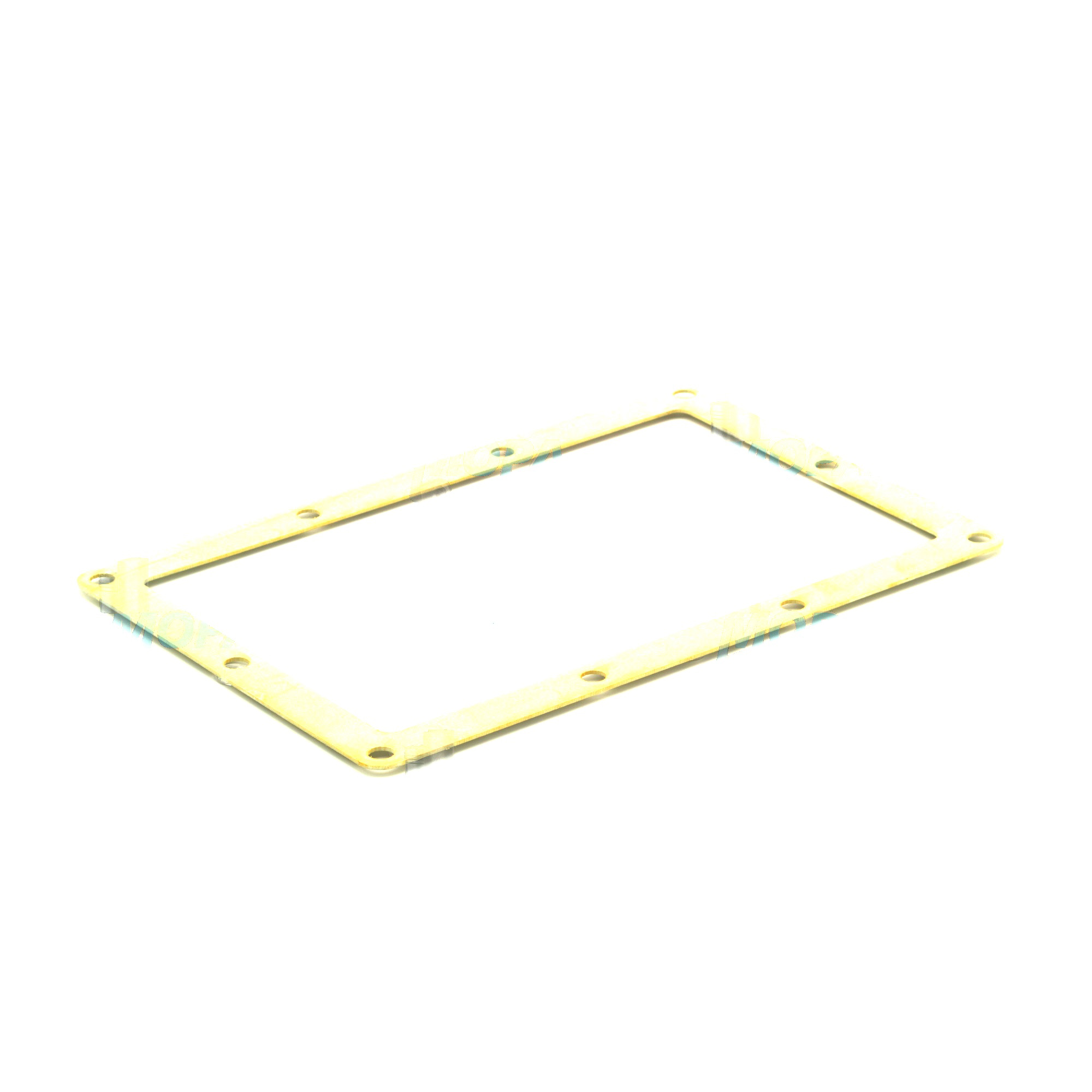

INTERCOOLER SEAL Gaskets for dependable engine performance

Gaskets are precision sealing elements that create reliable barriers between mating surfaces in engines and auxiliaries. They prevent the unintended flow of gases, air, oil, coolant, and exhaust, enabling stable operating conditions from start-up to full load. Within this category, the INTERCOOLER SEAL is a specialized gasket that ensures tightness in charge-air paths between turbocharger, intercooler, and intake manifold—vital for maintaining boost pressure, clean combustion, and safe operation.

From cylinder head and exhaust manifold to oil pan and pump flanges, gaskets are small components with outsized impact. They compensate for surface irregularities, absorb vibration, and maintain sealing force across thermal and pressure cycles. In high-output diesel and gas engines—especially in marine engine environments exposed to salt, humidity, and long duty cycles—the quality and condition of gaskets directly influence power, fuel economy, and emissions.

Technical function of Gaskets and the INTERCOOLER SEAL in diesel engine and marine engine applications

Gaskets work by providing a compressible interface between rigid components. When correctly torqued, they conform to micro-roughness in the flange faces, distributing load to achieve a uniform, gas- and fluid-tight seal. Materials range from elastomers (NBR, FKM, silicone) and fiber-reinforced composites to graphite and multi-layer steel, each selected for the medium, temperature, and pressure. Design factors include thickness, hardness, compression set, creep relaxation, and chemical compatibility with oils, coolants, fuel, and combustion byproducts.

The INTERCOOLER SEAL has a focused task: preserve boost pressure and airflow integrity across charge-air cooler connections. In a diesel engine, even minor leakage between the compressor outlet, intercooler end tanks, and intake runners reduces air density, upsetting the air–fuel ratio and increasing specific fuel consumption. In a marine engine running at constant load, a leaking INTERCOOLER SEAL can elevate exhaust temperatures, trigger turbocharger overspeed, and accelerate fouling. Correct geometry, durometer, and lip design ensure the seal resists extrusion under pulsating pressure, while material selection guards against oil mist, ozone, temperature cycling, and salt-laden atmospheres.

Gaskets also safeguard safety-critical boundaries: preventing coolant–oil cross-contamination, containing exhaust gases before turbo machinery, and maintaining vacuum or pressure in auxiliary systems. In all cases, the seal must retain elasticity over time, recover after thermal expansion, and resist micro-movement that otherwise leads to fretting and leakage. INTERCOOLER SEAL OEM parts are engineered to deliver consistent compression and mating tolerances across housings, pipes, and clamps—key to predictable torque-to-seal performance.

- · Reliable sealing under pulsating pressure and thermal cycling.

- · Chemical resistance to oils, coolants, fuel, and salt-laden air.

- · Precise dimensions for stable torque retention and easy assembly.

- · Low compression set to preserve long-term elasticity.

- · Protection of boost pressure and air density for efficient combustion.

- · Reduced risk of hotspots, turbo overspeed, and component wear.

- · Support for emissions compliance and stable engine mapping.

Why Gaskets and the INTERCOOLER SEAL are critical for engine reliability

When gaskets degrade, performance and reliability suffer quickly. A compromised INTERCOOLER SEAL in a marine engine or diesel engine can cause boost loss, delayed turbo spool, and smoke due to richer fueling. The engine management system may compensate by increasing fueling rates, driving up exhaust gas temperatures and thermal stress on valves and turbochargers. Over time, this leads to higher maintenance costs and unplanned downtime.

Elsewhere, coolant gasket failures risk cross-leaks that dilute lubricants and strip bearing films. Exhaust gasket leaks ahead of the turbo reduce available energy for the turbine, cutting power and increasing fuel burn. Oil gasket leaks raise fire risk and contaminate engine rooms. Across all scenarios, the health of gaskets dictates the stability of critical boundaries—and therefore the service life of major components.

Advantages of OEM spare parts suitable for Gaskets and the INTERCOOLER SEAL

Choosing OEM spare parts suitable for your gaskets and INTERCOOLER SEAL protects engine performance and budgets alike. These parts are manufactured to the precise drawings, tolerances, and material specifications required by the engine design. That precision translates to faster installation, consistent torque values, and predictable sealing behavior under real load cases.

Material fidelity matters: the correct polymer blend or graphite grade ensures low compression set, proper hardness, and resistance to hydrocarbons and high temperature. Dimensional consistency across batches supports planned maintenance, while validated compounds extend service intervals and reduce leakage-related fuel penalties. For operators, this means fewer interventions, better asset utilization, and stable lifecycle cost.

Key benefits of using OEM parts for Gaskets and INTERCOOLER SEAL OEM parts

- · Exact fit for flanges, housings, and charge-air connections.

- · Tested materials for heat, pressure, and chemical exposure.

- · Stable sealing force and reduced retorque requirements.

- · Lower risk of boost leaks and cross-contamination.

- · Proven durability that supports longer overhaul intervals.

- · Traceability and documentation that ease compliance.

MOPA: fast, quality-assured supply of INTERCOOLER SEAL and Gaskets OEM parts

MOPA is an experienced partner for OEM spare parts suitable for Gaskets across diesel and gas engines. We source and deliver INTERCOOLER SEAL components and comprehensive gasket sets with a focus on speed, quality, and transaction security. Our team supports purchasers and technical decision-makers with accurate cross-references, material insights, and application guidance for marine engine, power generation, and industrial duty cycles.

With streamlined logistics and controlled sourcing, MOPA helps minimize downtime and ensures parts arrive ready for installation. From single INTERCOOLER SEAL items to full overhaul gasket kits, we provide consistent quality, documentation, and dependable lead times—so your engines return to service quickly and operate at their designed efficiency.

Conclusion: the value of quality Gaskets and the INTERCOOLER SEAL

Gaskets—especially the INTERCOOLER SEAL in charge-air systems—are foundational to engine efficiency, safety, and longevity. Correct materials, precise dimensions, and verified performance keep boost pressure, fluids, and exhaust exactly where they belong.

OEM spare parts suitable for Gaskets and the INTERCOOLER SEAL secure consistent sealing behavior, protect budgets through fewer interventions, and support reliable operation. With MOPA as your partner, you gain fast, secure access to the right parts for diesel and gas engines, every time.