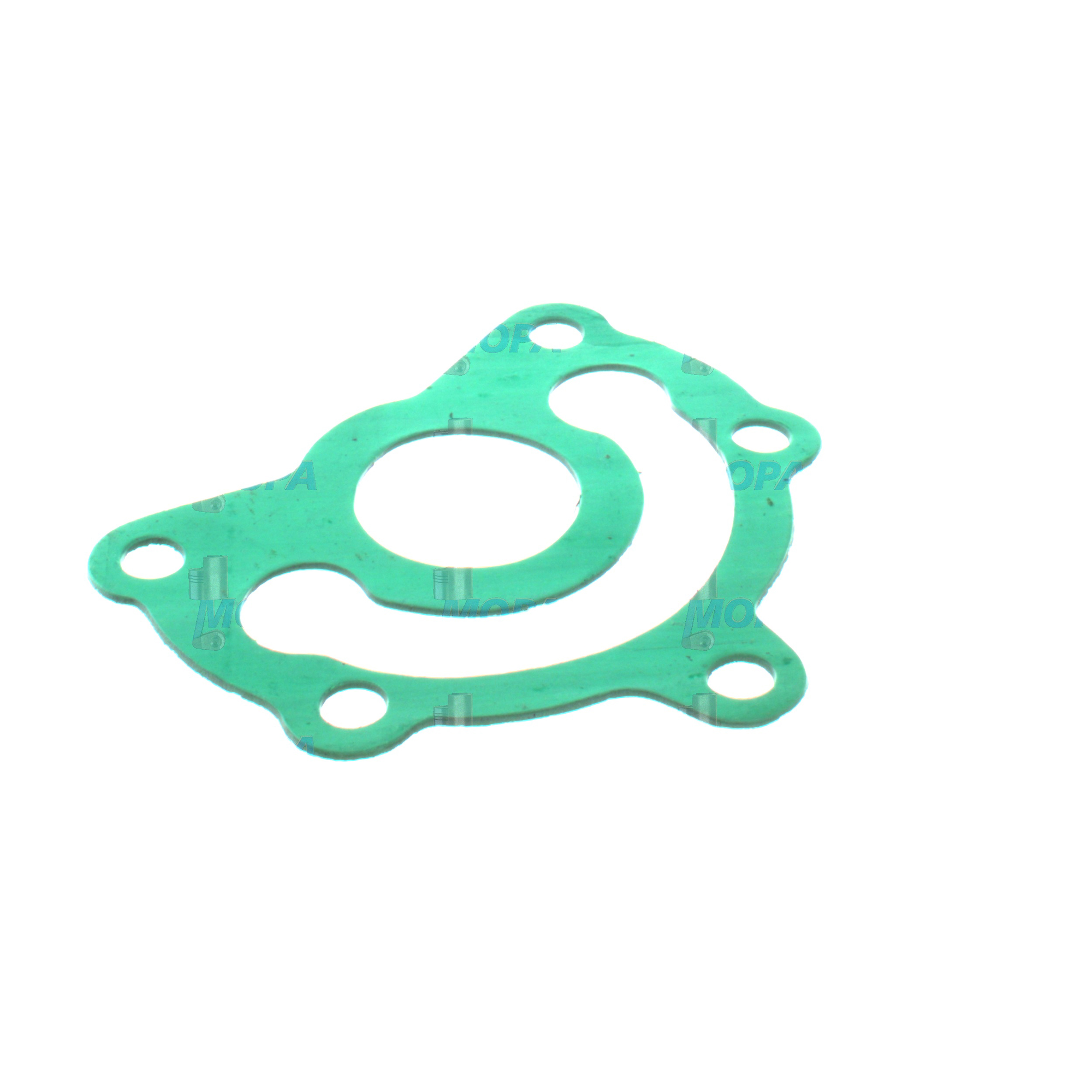

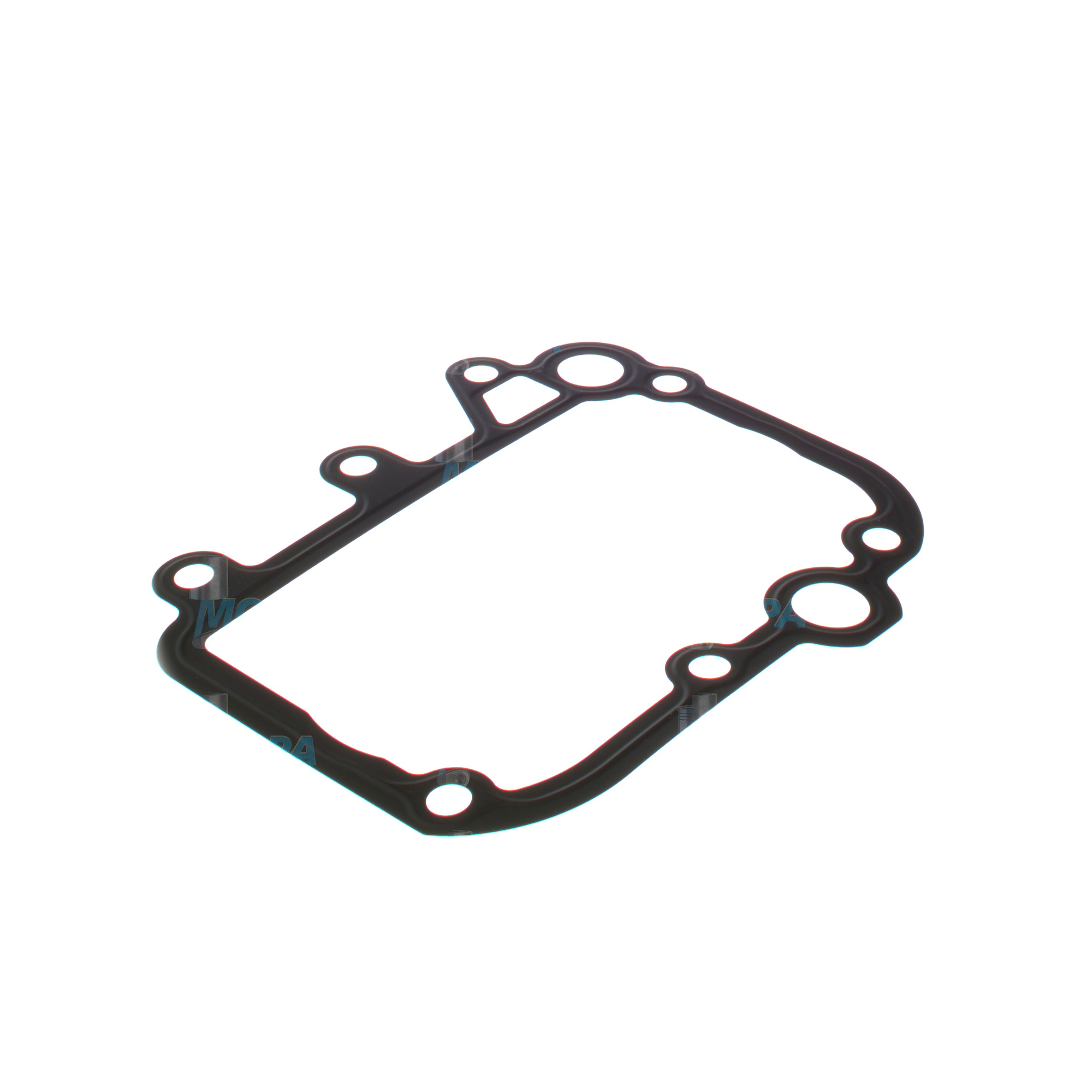

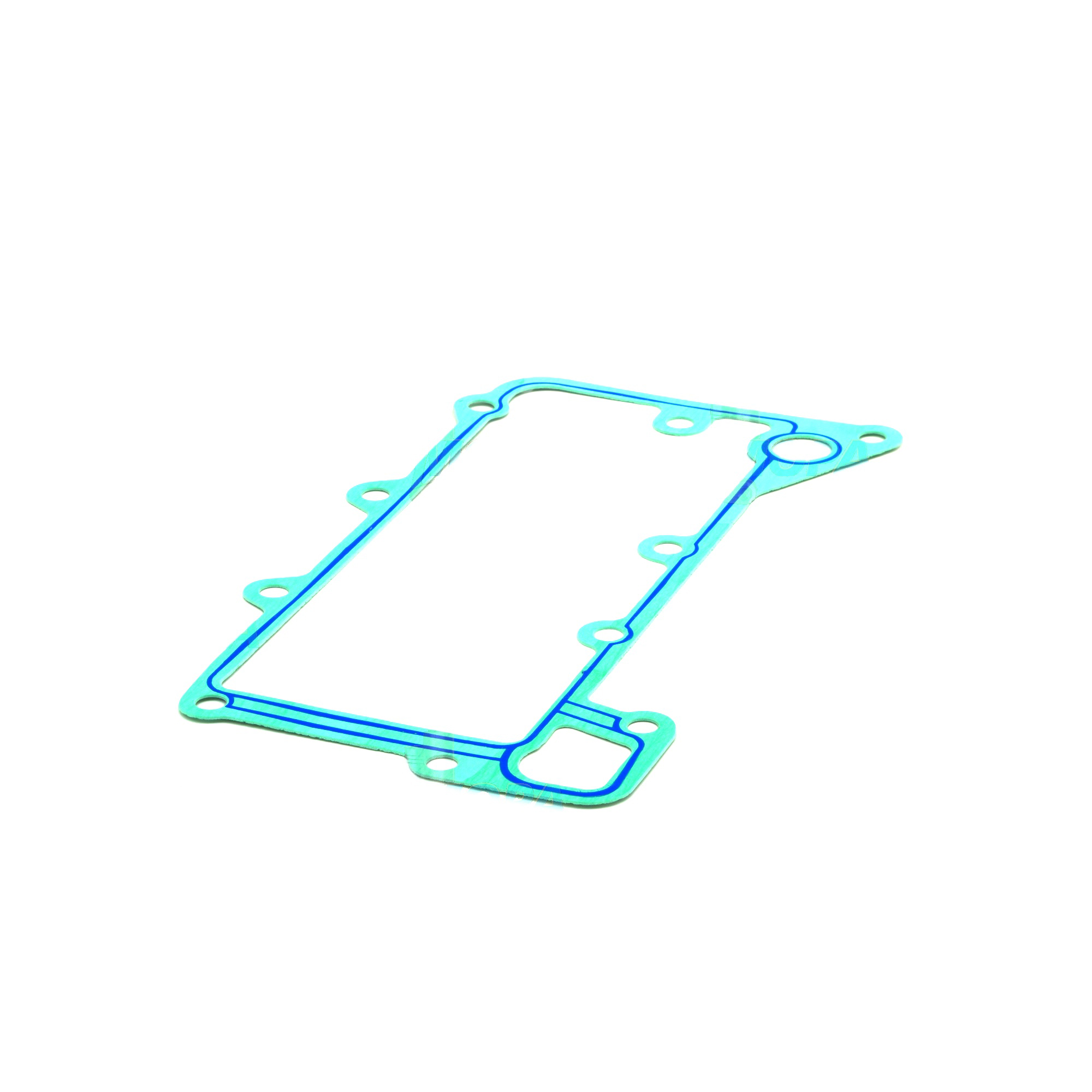

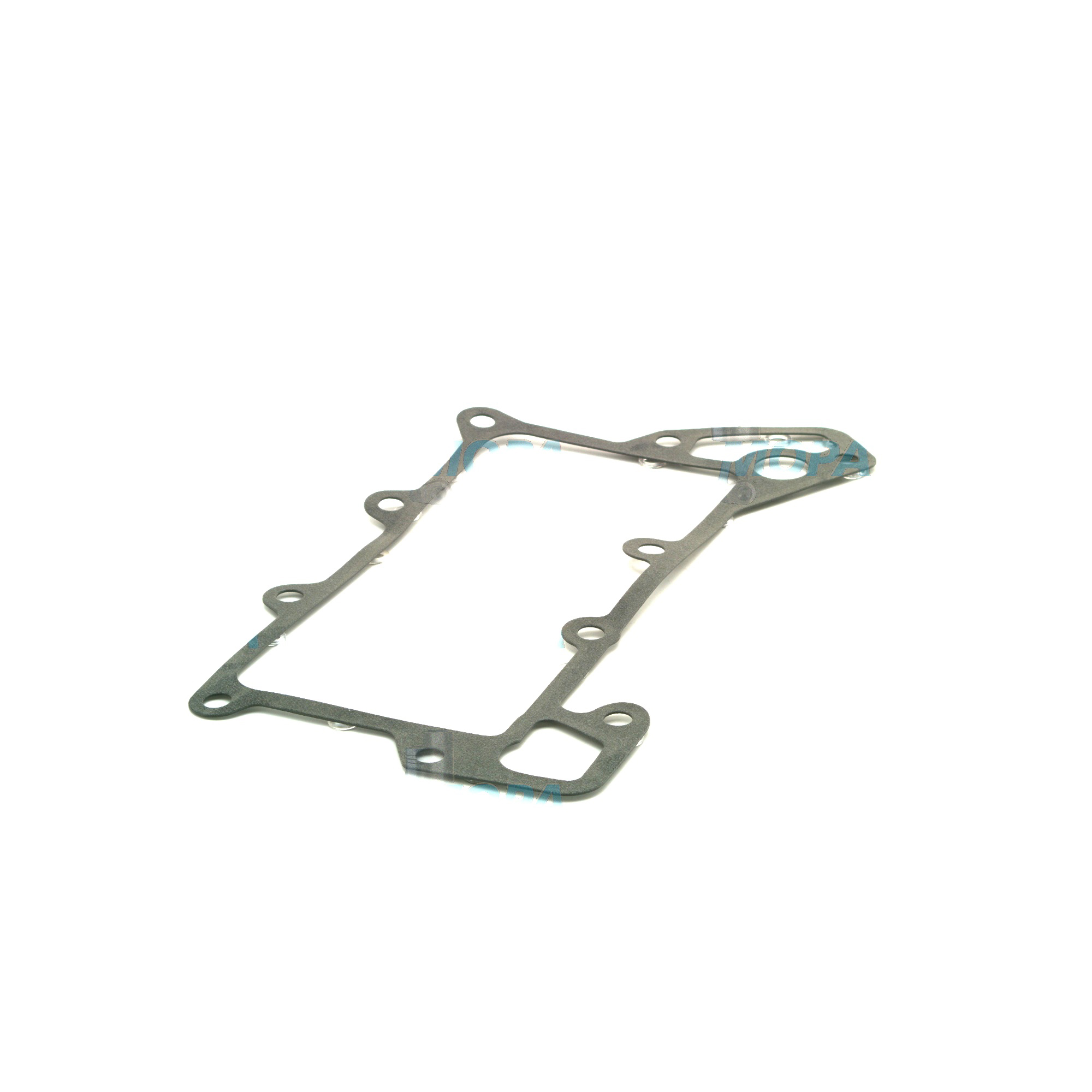

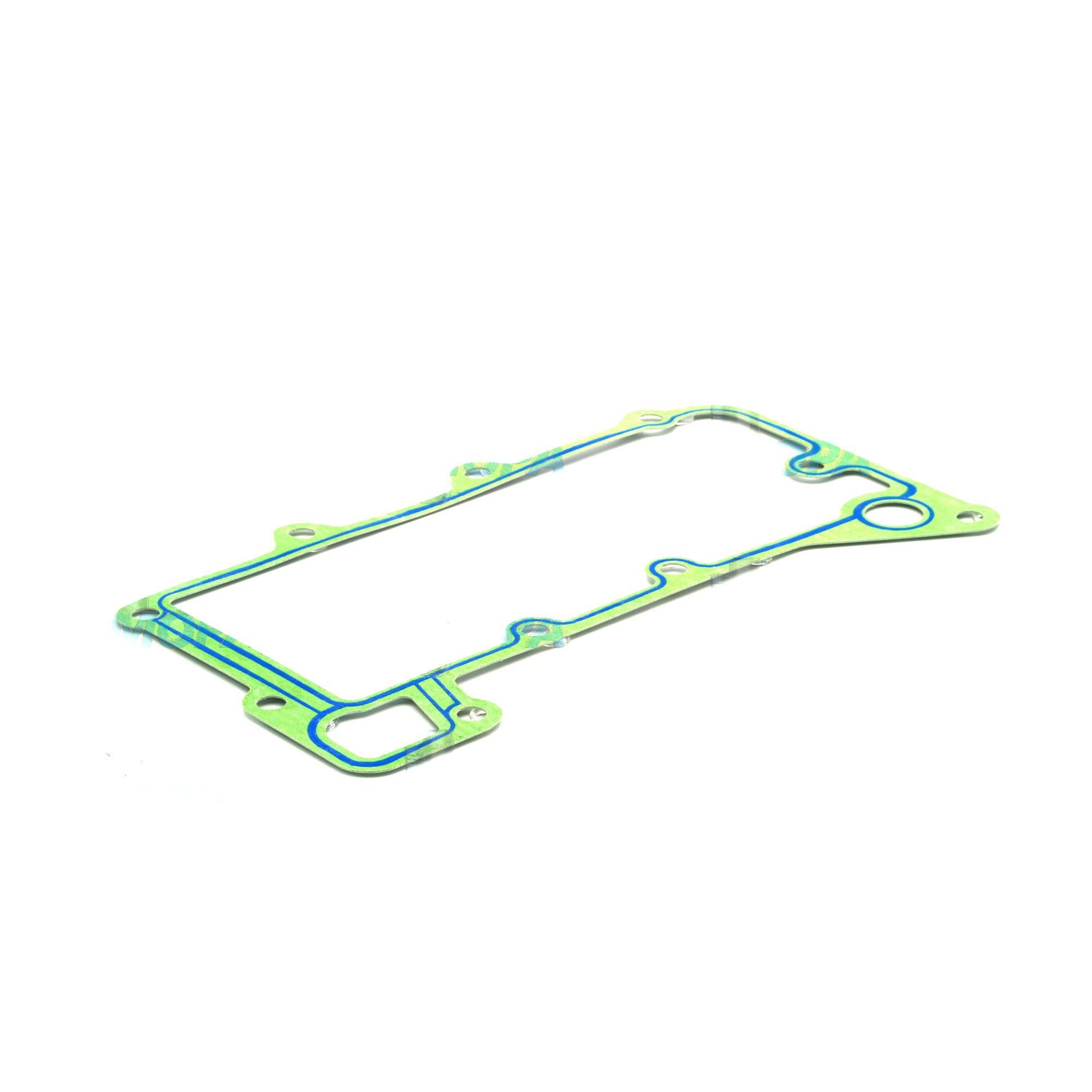

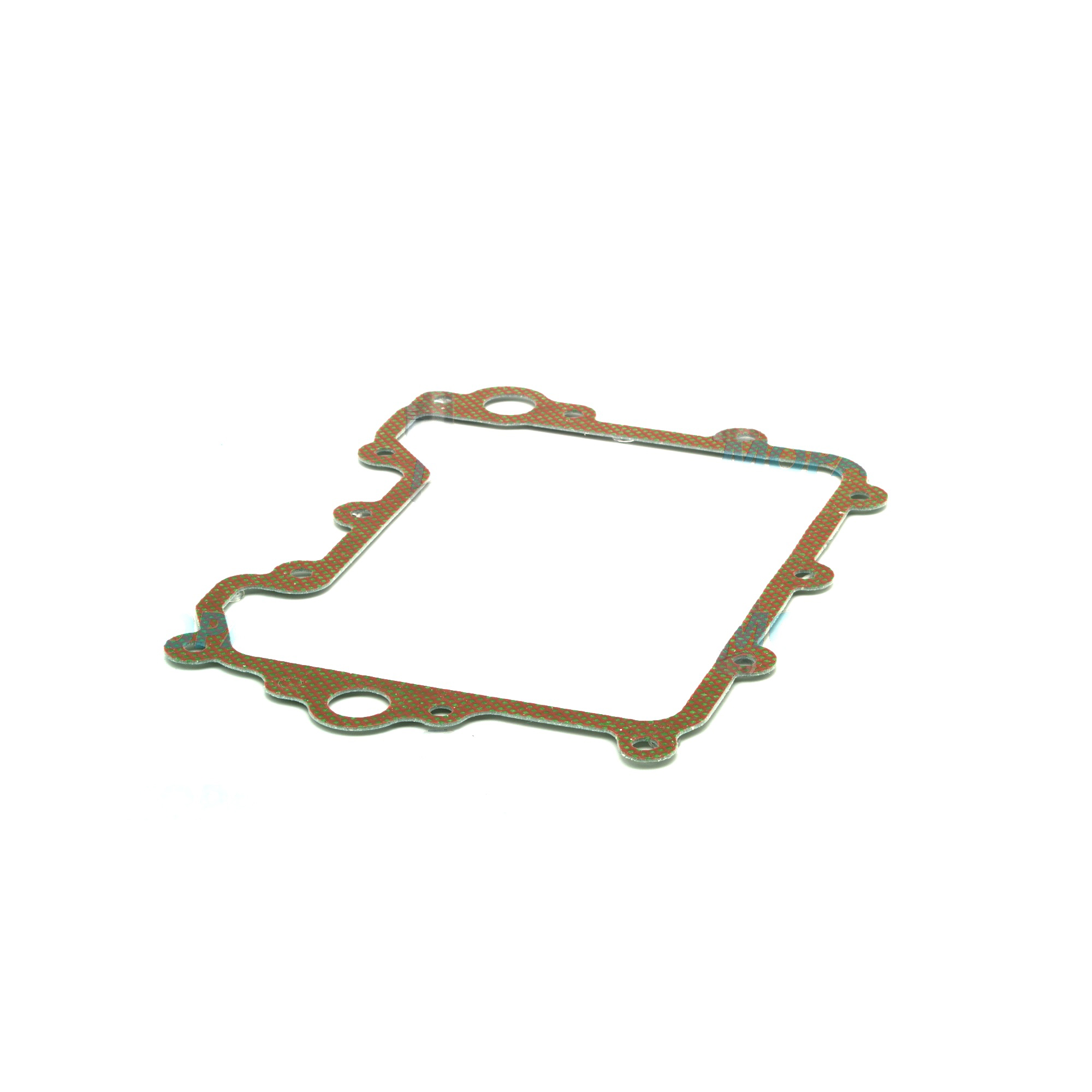

OIL COOLER GASKET Gaskets for High-Performance Diesel and Marine Engines

Gaskets are precision sealing components that sit between mating surfaces in an engine and keep fluids, gases, and pressure where they belong. As a broad article category, gaskets include everything from cylinder head seals and exhaust manifold seals to pump, cover, and heat-exchanger interfaces. Without the right gasket at each joint, engines cannot maintain lubrication, cooling, or combustion integrity. In demanding applications—such as a marine engine operating continuously at variable loads or a power-generation diesel engine at baseload—gaskets protect performance, efficiency, and safety by preventing leaks and cross-contamination.

Within this category, the OIL COOLER GASKET has an especially critical job. It seals the interface between the engine block or housing and the oil cooler module, ensuring oil flows through the cooler without mixing with coolant or leaking externally. A robust sealing solution preserves oil pressure, stabilizes operating temperature, and avoids the cascading failures that result from contamination or oil starvation. This makes gaskets a small part with outsized impact on uptime and total cost of ownership.

Technical function: Gaskets and the OIL COOLER GASKET in diesel and marine engines

Gaskets operate by conforming to micro-roughness on flange surfaces and creating a barrier under clamp load. The right material and construction—elastomer-coated steel, aramid fiber with nitrile binder, graphite, or multi-layer steel—manage temperature, pressure, vibration, and chemical exposure. For an OIL COOLER GASKET on a diesel engine or gas engine, this means resisting hot oil, coolant additives, and thermal cycling while maintaining compressive recovery over thousands of hours.

In a marine engine, the OIL COOLER GASKET must hold seal integrity despite hull vibrations, start–stop stress, and variable oil viscosity. Surface finish, flange flatness, and correct bolt torque are integral to the sealing design. When specified as OEM parts, the OIL COOLER GASKET’s geometry, bead profiles, and compressed thickness are matched to the cooler core and housing, ensuring uniform contact pressure and avoiding pinch points or blowouts. This precise fitment keeps the thermal management circuit efficient, stabilizes oil temperatures, and supports reliable hydrodynamic bearing lubrication.

- · Tight sealing under thermal cycling.

- · Resistance to oil, coolant, and fuel contaminants.

- · Correct compressed thickness for stable clamping.

- · Materials engineered for pressure and vibration.

- · Prevents oil–coolant cross-leaks.

- · Supports consistent oil pressure and temperature.

- · Reduces risk of unplanned shutdowns.

Why gaskets matter: Reliability, efficiency, and safety

Engines depend on stable lubrication and temperature control to deliver rated output and efficiency. Gaskets maintain these conditions by sealing critical interfaces. When a gasket wears, hardens, or is incorrectly installed, several issues can arise:

Failure modes linked to an OIL COOLER GASKET

Loss of oil pressure due to external leakage can starve bearings, scuff cylinder liners, and accelerate turbocharger wear. If oil and coolant mix through a compromised OIL COOLER GASKET, sludge forms, heat transfer drops, and corrosion accelerates inside galleries. The result can be overheating, bearing wash-out, and severe engine damage. In marine service, oil in coolant or coolant in oil also creates environmental and safety risks, triggers alarms, and may force unscheduled port calls. For power generation or industrial duty, the same failure translates into costly downtime and penalties for not meeting contractual output.

By maintaining a reliable seal, gaskets help sustain design clearances, protect auxiliary systems, and keep the engine operating within its optimal thermal window. Correct sealing directly influences fuel economy, emissions stability, and component life across the entire lubrication and cooling circuit.

Advantages of OEM spare parts suitable for Gaskets and the OIL COOLER GASKET

Using OEM spare parts suitable for gaskets provides measurable technical and commercial benefits. These components are built to the engine maker’s drawings and material specifications, so bead geometry, thickness, and compressive modulus match the flange design. For an OIL COOLER GASKET, this precision ensures even clamp loads and long-term recovery—vital for preventing micro-leaks that grow into major failures.

OEM spare parts suitable for gaskets also offer material compatibility with modern lubricants and coolants, including low-ash oils for gas engines and higher bio-content fuels that can challenge generic sealing materials. The result is predictable performance, longer service intervals, and fewer repeat interventions. From a budget perspective, the savings from avoided downtime, reduced rework, and safeguarded major components far exceed any small difference in purchase price. Traceable batches and consistent quality control further reduce risk in safety-critical operations.

How OEM spare parts support performance and lifecycle

Precision tolerances help maintain target oil pressure and coolant isolation. Thermal stability and chemical resistance extend gasket life in high-load cycles. Consistency across batches simplifies fleet maintenance planning, allowing shipowners and plant managers to standardize torque specs, sealants, and inspection intervals. All of this contributes to a robust maintenance strategy that keeps engines on spec and on schedule.

MOPA: Your partner for OEM spare parts Gaskets and OIL COOLER GASKET procurement

MOPA is an experienced and reliable partner for OEM spare parts suitable for gaskets across diesel and gas engines. We move fast—quoting, picking, and shipping with short lead times to minimize downtime. Our focus on quality and security means vetted sourcing, full traceability, and careful packaging that protects sensitive sealing surfaces.

Whether you operate a marine engine, power-plant prime mover, or industrial compressor drive, MOPA supports you with application expertise, cross-referencing by part number, and technical documentation. We help you select the correct OIL COOLER GASKET, cylinder head gasket, or auxiliary pump gasket so that fitment, materials, and performance align with your engine’s demands.

Conclusion: Gaskets and the OIL COOLER GASKET keep engines efficient and safe

Gaskets are essential sealing components that protect oil pressure, cooling performance, and overall engine health. The OIL COOLER GASKET is pivotal in preventing leaks and cross-contamination that lead to costly failures. Choosing OEM spare parts suitable for gaskets delivers reliable performance, longer service life, and better control of maintenance costs—backed by MOPA’s speed, quality, and secure supply for diesel and gas engines.