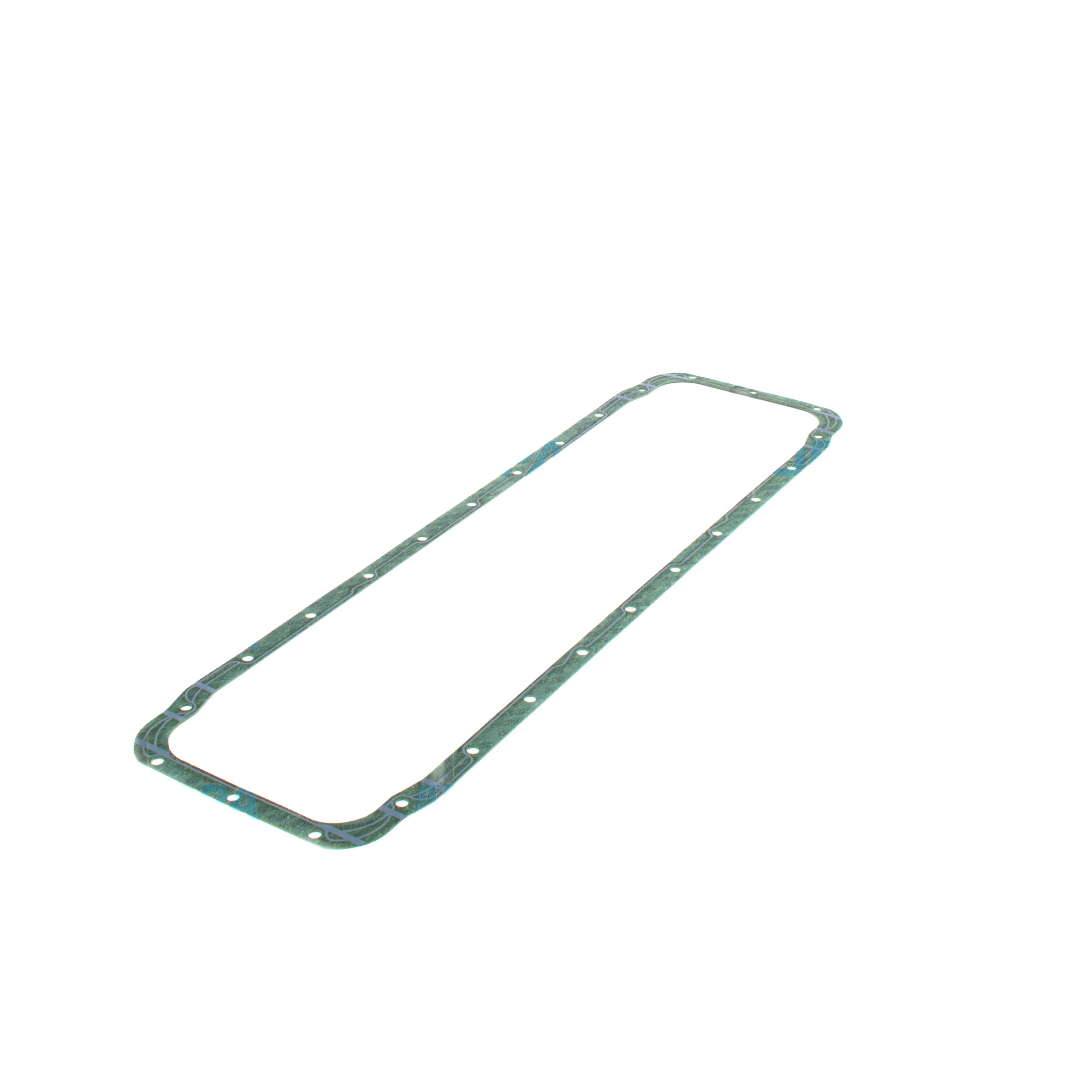

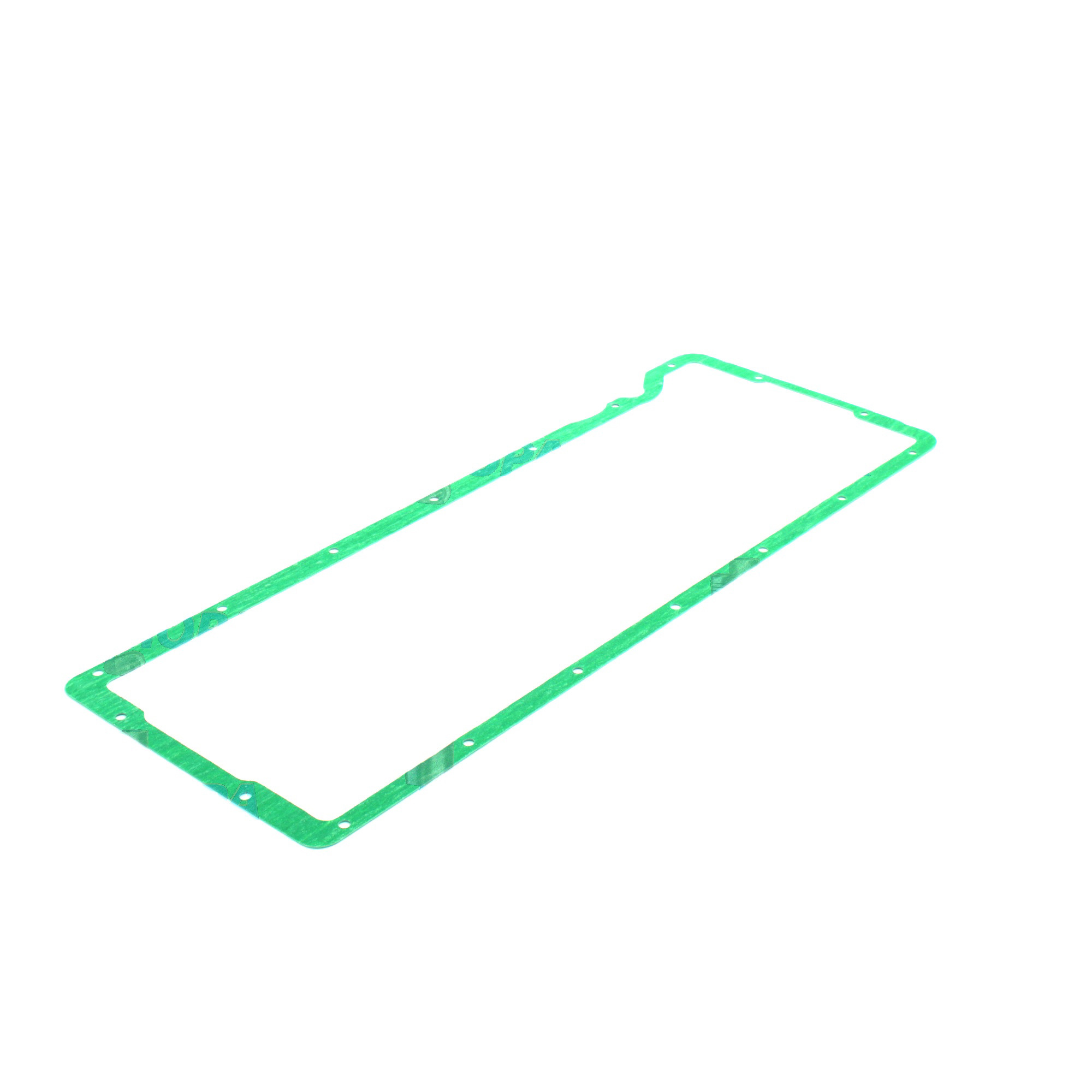

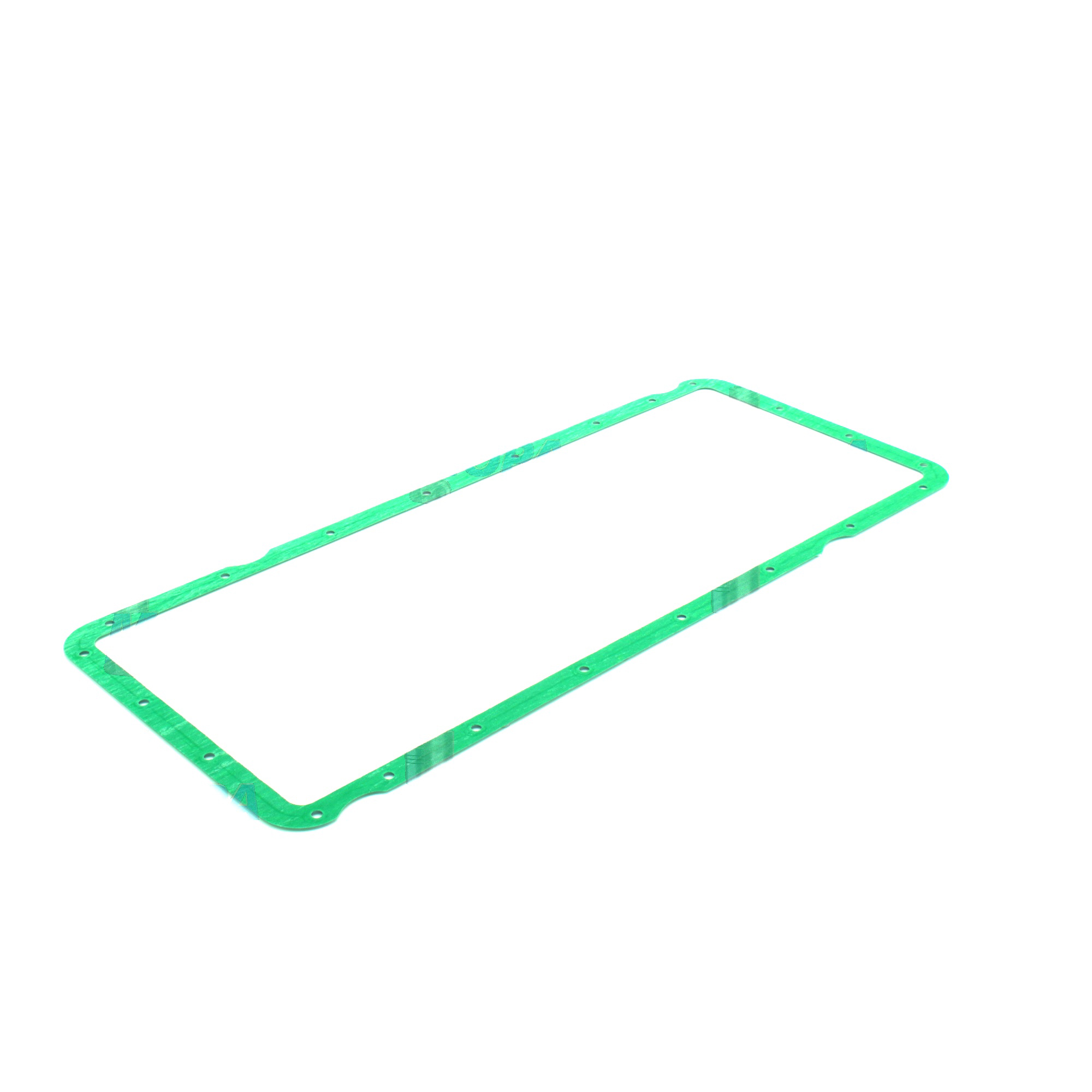

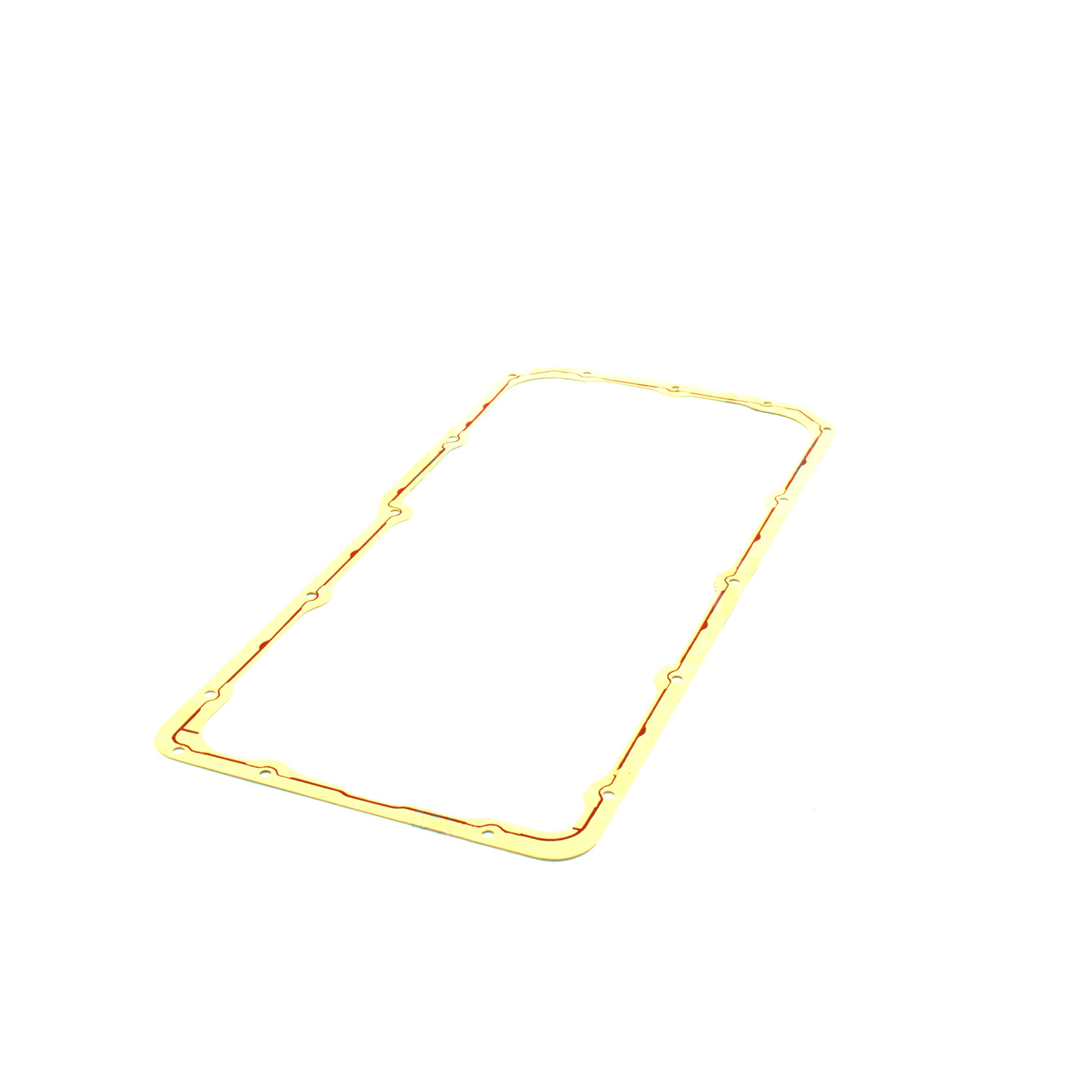

OIL PAN GASKET and Gaskets for High-Performance Diesel and Marine Engines

Gaskets are precision sealing elements that sit between two mating surfaces in an engine to prevent the escape or ingress of fluids and gases. As a category, gaskets include the OIL PAN GASKET, head gaskets, exhaust and intake gaskets, and many specialized seals used across diesel and gas engines. They maintain system integrity under heat, pressure, vibration, and chemical exposure—making them indispensable for lubrication, cooling, combustion management, emissions control, and overall engine safety. For purchasers, shipowners, and technical decision-makers, selecting the right gaskets is a direct lever for uptime, total cost of ownership, and compliance.

Technical Function: How Gaskets and the OIL PAN GASKET Enable Reliable Engine Operation

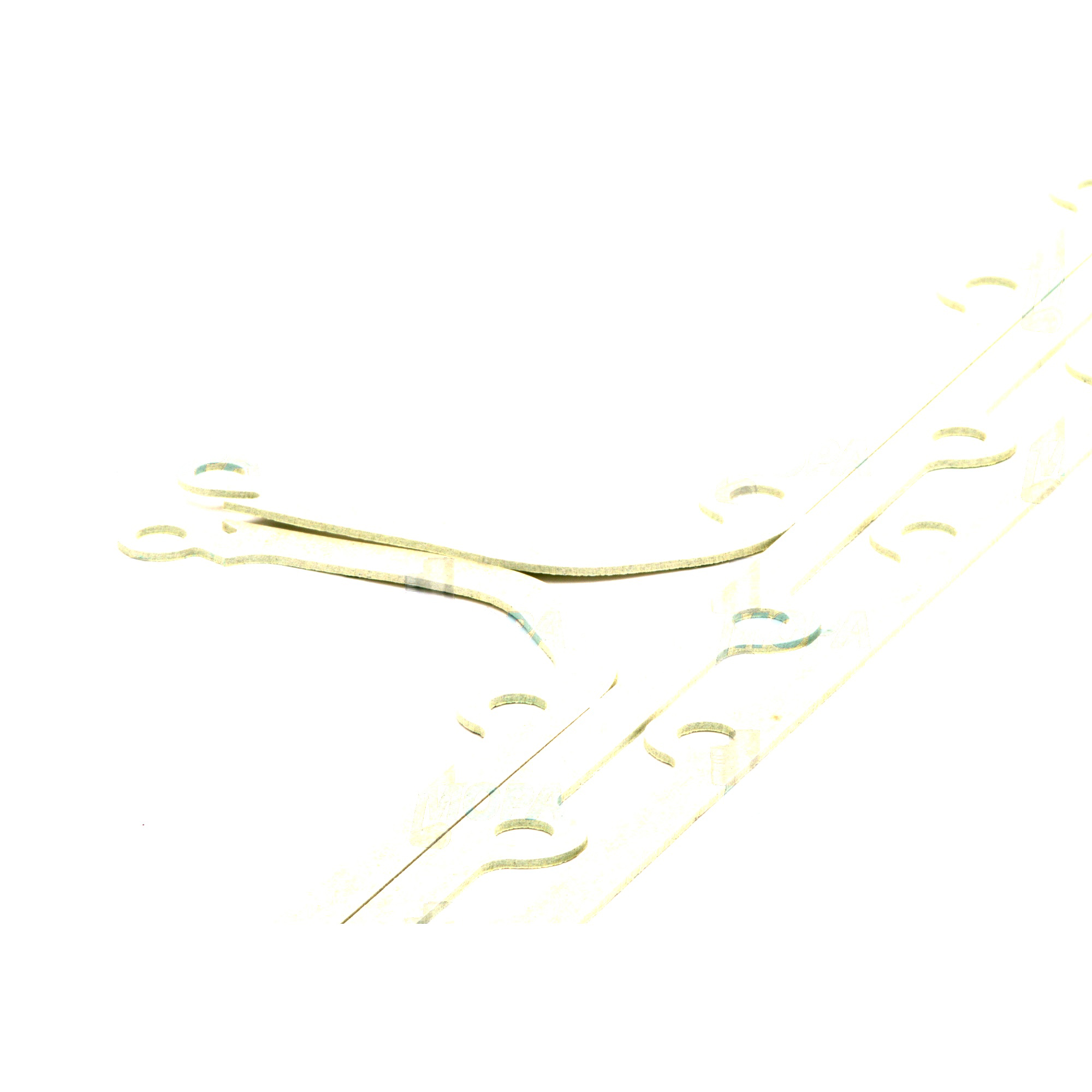

Across engine subsystems, gaskets create a micro-tight seal that compensates for surface roughness, thermal expansion, and flange distortion. Materials range from elastomers (NBR, FKM) and fiber-reinforced composites to multi-layer steel (MLS) and graphite with steel carriers. Each design balances compressibility, recovery, creep resistance, blowout strength, and chemical compatibility with engine oils, coolants, and exhaust condensates.

The OIL PAN GASKET specifically seals the interface between the crankcase and the oil sump. In a diesel engine, it must hold stable compression under cyclic vibration while maintaining oil tightness at both cold start and full operating temperature. In a marine engine, the OIL PAN GASKET also counters hull-induced torsional stress and extended base-load operation, helping protect against oil aeration and loss of net positive suction head at the pump pickup. A properly engineered OIL PAN GASKET supports consistent oil pressure, reduces the risk of bearing starvation, and minimizes environmental and housekeeping issues from leaks in engine rooms. In practice, this gasket works in tandem with bolt preload, flange flatness, and surface finish to achieve a durable seal; bead geometries, corner reinforcements, and carrier stiffness are tuned to the engine platform. When sourced as OEM parts, the OIL PAN GASKET is matched to the exact flange geometry, fastener pattern, and thermal envelope of the engine design.

- · High chemical resistance to engine oils, fuel dilution, and additives.

- · Temperature stability across cold starts and high-load operation.

- · Controlled compressibility for reliable preload retention.

- · Robust bead and carrier design for vibration and shock loads.

- · Low permeability to reduce evaporative and drip losses.

- · Tight dimensional tolerances for precise fit and easy installation.

- · Material options (NBR, FKM, MLS, fiber) to match engine duty.

- · Proven blowout resistance and long service intervals.

Importance for Engine Operation: Why Gaskets Determine Reliability and Service Life

Gasket performance directly affects engine availability. Loss of sealing can trigger cascading failures: oil leaks from a degraded OIL PAN GASKET reduce oil level and pressure, accelerating wear on main and rod bearings, turbocharger bushings, and camshaft journals. Persistent misting can contaminate belts and electrical components, degrade engine mounts, and create slip hazards onboard. Coolant and combustion gaskets, if compromised, increase the risk of overheating, detonation, and emissions non-compliance. Over time, thermal cycling and bolt relaxation can cause compression set; if the gasket material lacks recovery, micro-channels form, leading to seepage. Conversely, overcompression or incorrect torque sequence can pinch or extrude the gasket, shortening service life.

For fleet operators, the cost of a leaking OIL PAN GASKET is not only lost lubricant—it is downtime, clean-up, potential environmental penalties, and unplanned bearing inspections. Rigorous adherence to sealing specs—surface roughness (Ra), bolt torque and angle, curing time for sealants (if specified), and retorque procedures for certain composite designs—extends life and reduces risk. In short, the integrity of every gasket, and especially the OIL PAN GASKET, underwrites safe, efficient, and predictable engine operation.

Advantages of OEM Spare Parts Suitable for Gaskets and the OIL PAN GASKET

Choosing OEM spare parts suitable for gaskets ensures the sealing elements match the engine maker’s drawings, materials, and validation tests. This precision translates into measurable benefits for performance, reliability, budget control, and service life:

- · Engineered fit: Correct thickness, bead geometry, and bolt-hole alignment.

- · Material fidelity: Elastomer and steel grades proven for the engine’s fluids and temperatures.

- · Consistent compression: Predictable crush and recovery for long-term preload retention.

- · Reduced downtime: Faster installation with fewer rework cycles and leak callbacks.

- · Protects major components: Maintains oil pressure and prevents bearing and turbo damage.

- · Lower total cost: Fewer leaks, fewer top-ups, fewer unplanned stoppages.

- · Validated performance: Tested sealing under vibration, thermal gradients, and pressure pulses.

- · Compliance and documentation: Traceable batches supporting safety and audit needs.

For critical interfaces like the OIL PAN GASKET in a diesel engine or marine engine, these factors are the difference between leak-free operation and repetitive maintenance.

MOPA as a Partner for OEM Spare Parts Gaskets, Including the OIL PAN GASKET

MOPA is an experienced and reliable partner for OEM spare parts suitable for gaskets across diesel and gas engines. We combine speed, quality, and security in the sourcing and trade of OEM parts, helping operators maintain fleet readiness and budget certainty. With deep product knowledge of the OIL PAN GASKET and related sealing components, MOPA supports you from identification to delivery, ensuring form-fit-function alignment with your engine platform.

Fast Supply, Verified Quality, and Secure Transactions

Expect rapid quotations, concise technical clarification, and express shipping options to minimize downtime. Every shipment focuses on traceability and packaging integrity, and our team assists with part mapping by engine model and serial range. Whether you manage a single vessel or a global fleet, MOPA streamlines procurement of OEM gaskets for diesel and marine engine applications with consistent results.

Conclusion: The Role of Gaskets and the OIL PAN GASKET in Engine Reliability

Gaskets—especially the OIL PAN GASKET—are small components with outsized impact on lubrication stability, cleanliness, and engine longevity. Selecting OEM spare parts suitable for gaskets delivers the precision, durability, and consistency needed to protect performance and extend service life while controlling operating costs.