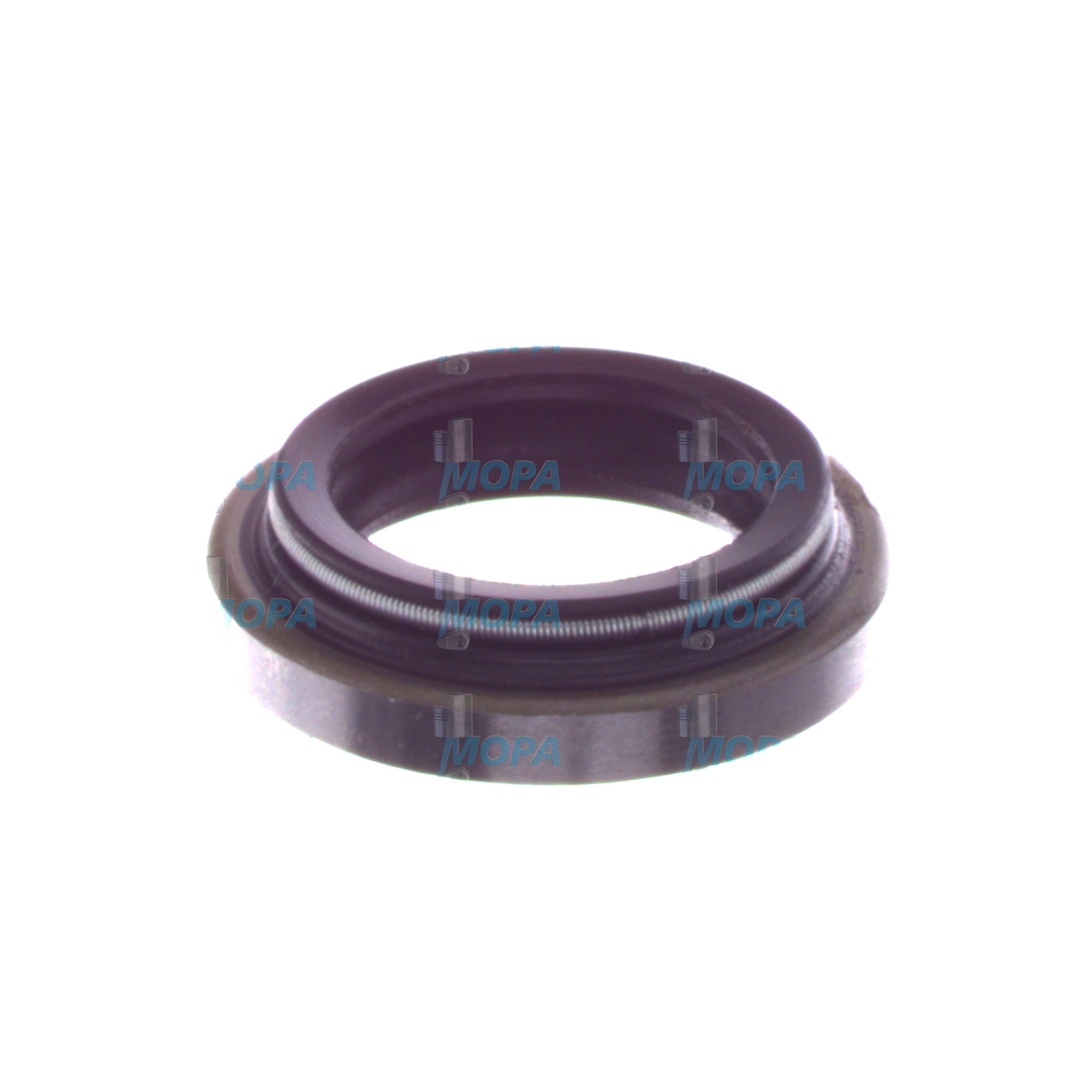

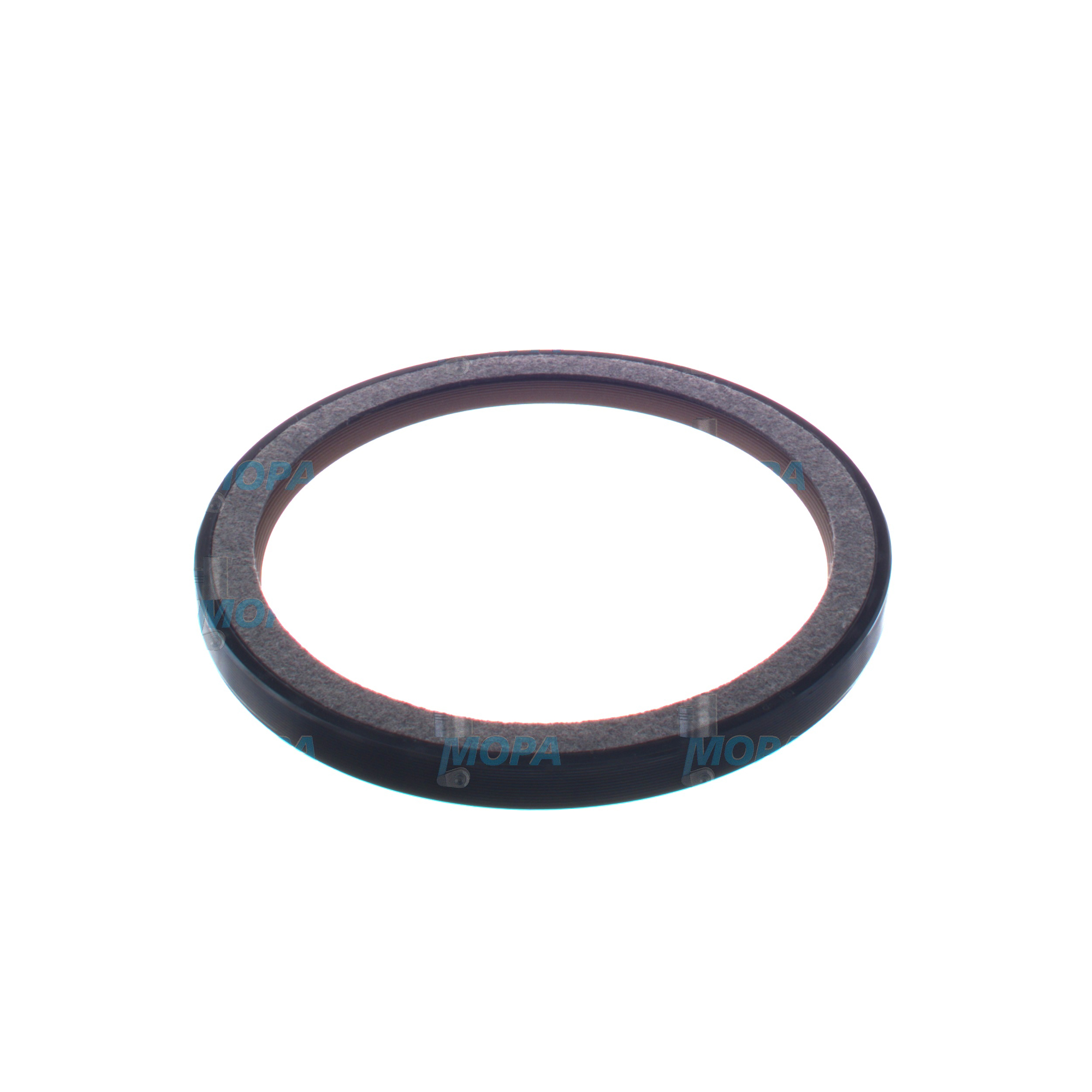

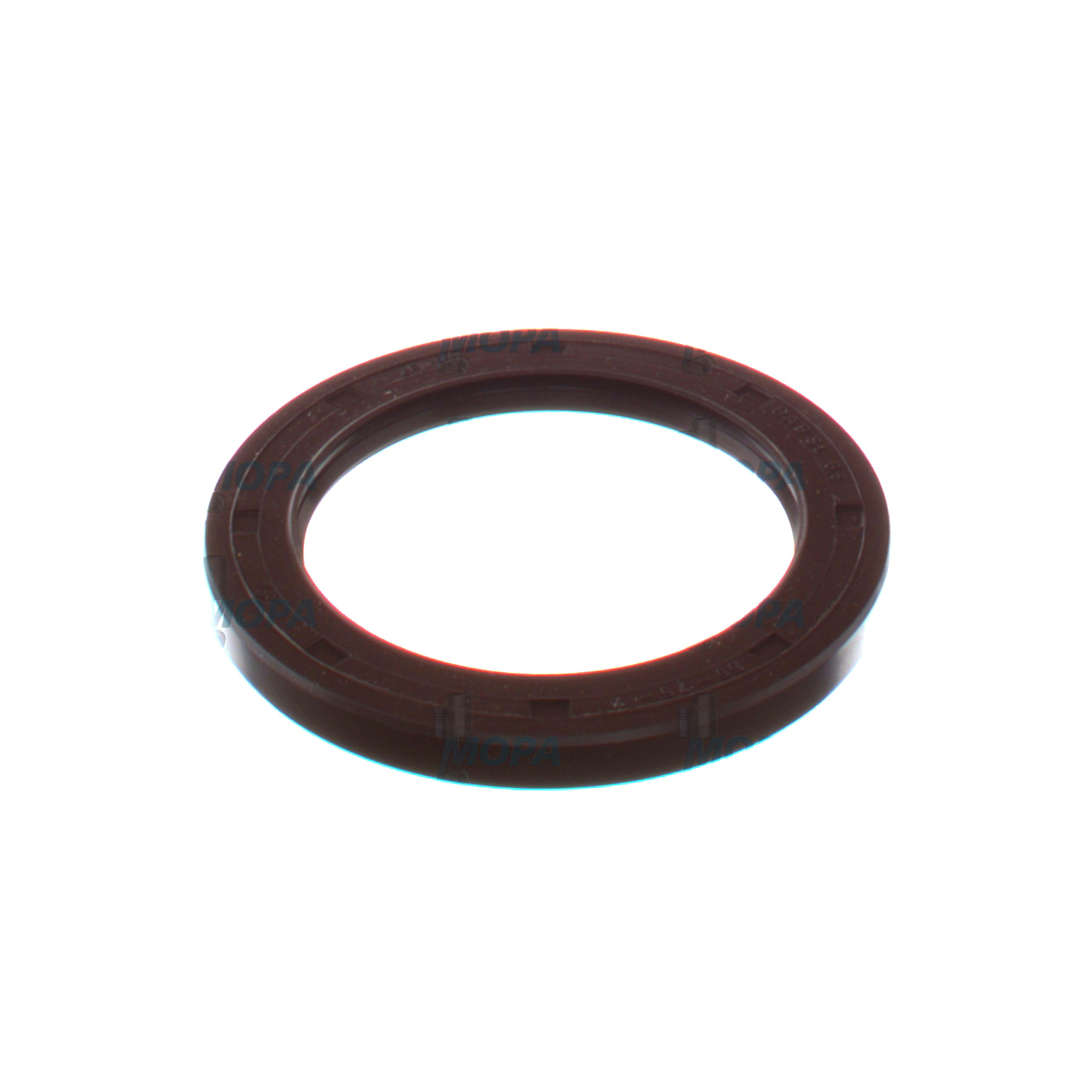

ROTARY SHAFT LIP SEAL – Gaskets for Marine and Diesel Engines

Gaskets are precision sealing components that ensure tight, reliable interfaces in engines and ancillary systems. They prevent the escape of combustion gases, lubricants, coolant, and exhaust, while keeping contaminants out of critical areas. From cylinder head gaskets to exhaust manifold gaskets, turbocharger gaskets, oil pan gaskets, and the dynamic sealing of a ROTARY SHAFT LIP SEAL at the crankshaft or camshaft, each element sustains the engine’s mechanical integrity. In marine engine and diesel engine applications, properly specified gaskets deliver stable compression, clean lubrication, controlled temperatures, and emissions compliance—key factors for vessels, power generation, and industrial operations.

As a category, gaskets bridge differences in surface flatness, thermal expansion, and bolt load, compensating for micro-irregularities to create a durable seal. Material choice—such as multi-layer steel (MLS), graphite, aramid fiber, elastomers like NBR/FKM, or PTFE—must align with temperature, pressure, and chemical exposure. When paired with correct surface finish and torque, these components protect performance while reducing life-cycle costs.

ROTARY SHAFT LIP SEAL and Gaskets: Technical Function in Engine Systems

In an engine, gaskets serve static interfaces, while a ROTARY SHAFT LIP SEAL handles dynamic sealing around rotating shafts. Cylinder head gaskets maintain combustion pressure between block and head, preserving power density and limiting blow-by. Exhaust and turbocharger gaskets ensure hot-gas containment for efficient turbo operation. Intake and throttle body gaskets stabilize airflow and metering. Oil pan and front cover gaskets keep lubricants where they belong, supporting consistent oil pressure and bearing protection. At the same time, the ROTARY SHAFT LIP SEAL marine engine application prevents oil leakage at crankshaft exits, protecting clutches, couplings, and surrounding machinery from contamination.

The ROTARY SHAFT LIP SEAL diesel engine configuration is engineered to manage shaft runout, temperature, and fluid compatibility. Its lip geometry, spring preload, and elastomer selection (e.g., FKM for high-temperature oil; PTFE for low friction and chemical resistance) are tuned to minimize wear and leakage over long operating intervals. In static joints, gasket compressibility, creep relaxation resistance, and recovery are crucial for torque retention and sealing under thermal cycling. Proper gasket seating and bolt load distribution reduce local stress peaks, avoid flange distortion, and protect against blowout.

- · Reliable sealing under thermal cycling.

- · Resistance to fuel, oil, coolant, and exhaust byproducts.

- · Stable compression and torque retention.

- · Materials matched to temperature and pressure ranges.

- · Low friction lip designs for rotating shaft interfaces.

- · Dimensional precision for tight tolerances and surface finishes.

- · Reduced leakage, emissions, and contamination risk.

- · Extended service intervals with consistent performance.

Why Gaskets Are Critical for Engine Reliability and Service Life

Gaskets protect the engine’s core functions: power generation, lubrication, and cooling. A properly specified head gasket maintains compression and avoids mixing of coolant and oil—both essential for efficiency and bearing longevity. Exhaust and turbocharger gaskets preserve energy in the hot-gas path, supporting boost response and lowering fuel consumption. Intake gaskets prevent unmetered air, keeping combustion stable and emissions controlled. The ROTARY SHAFT LIP SEAL OEM parts used on crankshaft and camshaft exits keep oil in and dirt out, reducing wear on seals, bearings, and couplings.

When gaskets or the shaft lip seal wear or are installed incorrectly, operators face oil loss, coolant ingress, power reduction, elevated emissions, and in severe cases, component damage due to starvation or overheating. Leaks can lead to safety hazards on deck or in the engine room, unplanned stops, and costly clean-up. Over time, creeping joint movement and thermal cycles can loosen flange loads, so high-quality sealing elements with the right recovery and chemical resistance are central to dependable engine availability.

Advantages of OEM Spare Parts Suitable for Gaskets and ROTARY SHAFT LIP SEAL

Choosing OEM spare parts suitable for gaskets and the ROTARY SHAFT LIP SEAL ensures dimensional accuracy, tested materials, and consistency across batches—factors that directly impact performance, reliability, budget, and service life. Precise tolerances secure proper seating on engine surfaces with the required roughness and flatness. Material recipes are validated for fuel variants, synthetic and mineral oils, coolant additives, and exhaust condensates often present in marine duty cycles.

Performance, reliability, and cost control with OEM spare parts

With OEM spare parts suitable for this category, purchasers and technical managers gain predictable sealing behavior, fewer re-tightening cycles, and reduced risk of rework. The result is longer maintenance intervals, stable compression and oil pressure, and lower total cost of ownership. For the ROTARY SHAFT LIP SEAL marine engine interface, OEM profiles and spring forces reduce friction and heat generation, supporting energy efficiency and shaft surface longevity. Traceable quality and documentation streamline approvals and help maintain compliance with class and safety requirements.

MOPA – Your Partner for OEM Gaskets and ROTARY SHAFT LIP SEAL Components

MOPA supplies OEM spare parts suitable for Gaskets and ROTARY SHAFT LIP SEAL applications across diesel and gas engines. As a trusted partner, MOPA prioritizes speed, quality, and security in the trade of OEM parts, helping shipowners and operators minimize downtime and risk. From cylinder head gaskets to camshaft and crankshaft seals, our portfolio covers key sealing points with components engineered for harsh marine and power generation environments.

Customers benefit from fast sourcing, technical guidance on material and fitment, and reliable logistics—so maintenance windows are met and engines return to service on schedule. MOPA’s focus on compliant, high-performance sealing solutions ensures consistent outcomes across fleets and facilities.

Conclusion

Gaskets—and the dynamic sealing delivered by a ROTARY SHAFT LIP SEAL—are foundational to engine integrity, efficiency, and safety. Specifying OEM spare parts suitable for gaskets safeguards performance, reliability, and service life while keeping budgets predictable. With MOPA as your partner, you secure high-quality OEM components for diesel and gas engines, delivered with speed and confidence.