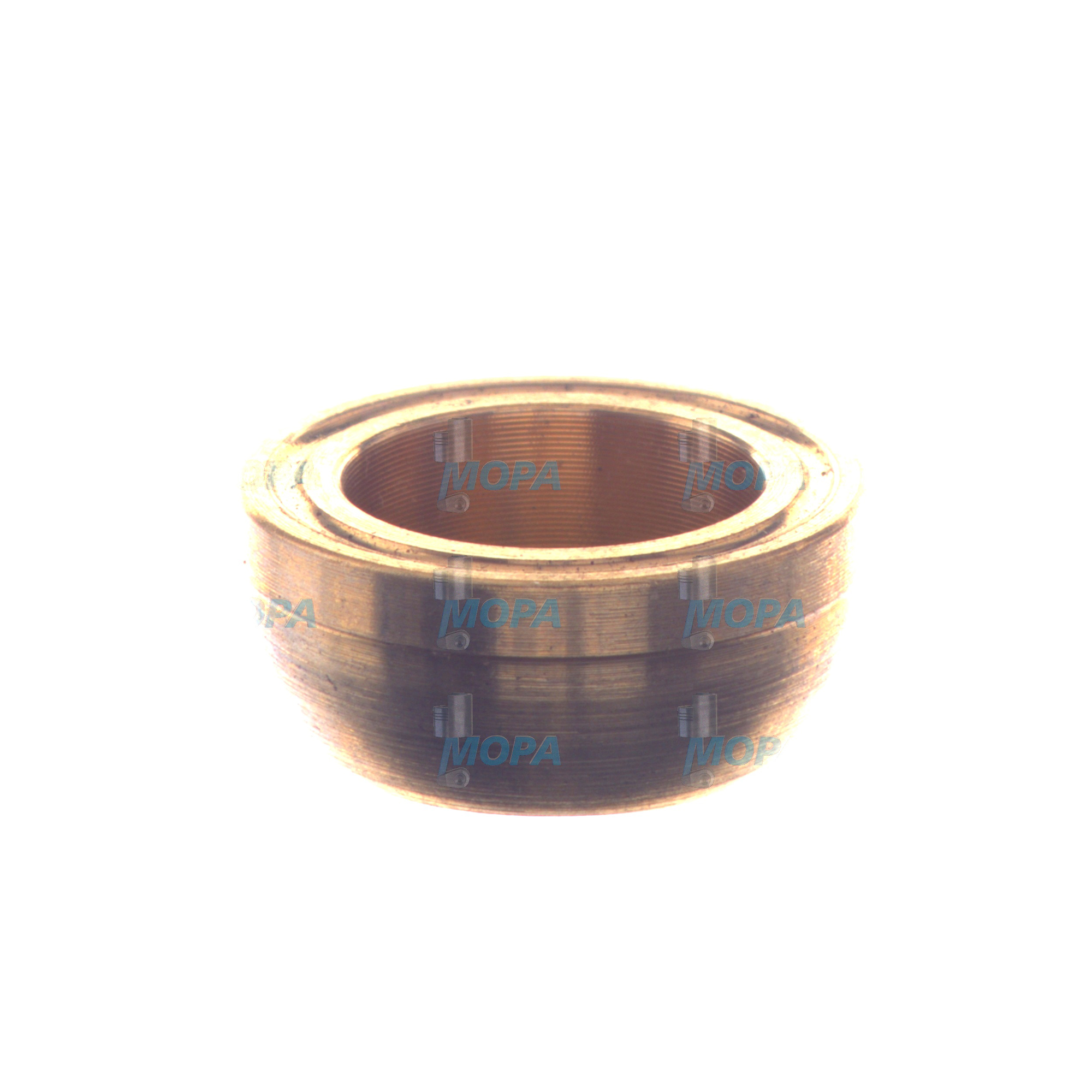

SEALING CONE and Gaskets for diesel and marine engines

Gaskets are precision sealing elements installed between two mating surfaces to prevent the escape or cross-contamination of gases and fluids. In engines, they close the micro-gaps created by machining tolerances and thermal movement, ensuring tightness across cylinder heads, turbochargers, exhaust manifolds, charge-air systems, coolant galleries, and lubrication circuits. Selecting the right gasket construction and compound is essential because engines operate under pulsating pressure, vibration, and extreme temperatures. Whether you run a high-output diesel engine on a vessel or a stationary gas engine in power generation, correctly specified gaskets underpin efficient combustion, clean emissions, safe operation, and predictable service life. The same engineering mindset that defines a precise SEALING CONE diesel engine connection also applies to gasket interfaces: geometry, surface finish, preload, and material compatibility must work together.

Technical function of Gaskets in engines and the role of SEALING CONE interfaces

Engine gaskets create a conformable barrier that compensates for surface irregularities and thermal expansion. Once clamped, they maintain a defined sealing stress over many cycles of heat-up and cool-down. Cylinder head gaskets, for example, must seal combustion pressures that can exceed 180 bar, while simultaneously isolating oil and coolant channels millimeters apart. Multi-layer steel (MLS) designs use embossed bead layers and stopper layers to control local contact pressure around fire rings and fluid ports. Elastomer-coated surfaces improve micro-sealing and anti-stick properties. In exhaust and turbocharger joints, spiral-wound or metal-reinforced graphite gaskets resist hot-gas erosion and bolt-load loss. In fuel, oil, and coolant systems, fiber-reinforced and PTFE-based composites balance compressibility, creep resistance, and chemical stability.

Mating hardware parameters determine success. Bolt preload must exceed internal pressure to maintain sealing stress; tightening sequence and torque-angle control minimize joint relaxation. Flange flatness and surface roughness (often Ra 3.2–6.3 µm for MLS head joints) are critical. Thermal gradients induce differential expansion; material stack-ups are chosen to retain clamp load despite creep and vibration. Where fittings use conical seats—as with injector lines and high-pressure rails—a SEALING CONE marine engine joint provides metal-to-metal tightness, while adjacent gaskets or washers manage auxiliary leakage paths, splash protection, or shielding. Proper pairing of gaskets with these SEALING CONE OEM parts ensures a continuous, leak-free envelope across the complete interface.

Key characteristics and advantages of Gaskets

· Maintain compression and prevent blow-by.

· Separate oil and coolant circuits safely.

· Resist thermal cycling and vibration.

· Match flange materials and surface finish.

· Withstand fuel, oil, coolant, and exhaust chemistry.

· Enable stable emissions and engine efficiency.

· Support safe operation and fire protection.

· Designed for predictable service intervals.

Materials, coatings, and engineering detail that drive performance

Material selection aligns with application conditions. MLS head gaskets use stainless spring steel with locally tuned embossments; graphite blends handle exhaust temperatures beyond 500°C; aramid- or cellulose-fiber composites suit moderate temperatures with hydrocarbon exposure; PTFE and FKM elements offer chemical resistance. Coatings reduce micro-leakage and assist disassembly. Stopper-layer geometry protects against bead over-compression. Engineers verify compressibility (e.g., per ASTM F36), stress relaxation (ASTM F38), and blowout resistance under realistic clamp loads. In practice, consistent machining, controlled torque, and clean assembly surfaces matter as much as the gasket itself—principles equally relevant at a SEALING CONE diesel engine seat where precision angles and surface integrity are mandatory.

Why Gaskets are critical for reliable engine operation

Gaskets directly influence reliability, uptime, and lifecycle cost. A leaking head gasket reduces compression, drives up fuel consumption, and can introduce coolant into the oil, accelerating bearing wear. Exhaust leaks before the turbo reduce boost, elevate EGT, and threaten surrounding components. Oil leaks increase fire risk and contaminate insulation; coolant leaks corrode sensors and mounts. Even minor weeping indicates degraded clamp load or surface mismatch and often precedes a larger failure. On a marine engine, a preventable seal failure can mean costly off-hire, unplanned bunkering delays, or non-compliance with environmental rules.

Typical root causes include improper torque sequencing, reused fasteners with insufficient preload, flange distortion, debris on sealing faces, incorrect material selection, or aging and creep in the gasket media. Condition-based maintenance—pressure tests, oil analysis for glycol, visual inspections for soot tracks and salt deposits—helps identify early-stage issues. Replacing compromised gaskets and re-establishing correct clamping forces restore efficiency and extend the service interval of adjacent components.

Advantages of OEM spare parts suitable for Gaskets and SEALING CONE OEM parts

Using OEM spare parts suitable for Gaskets ensures that geometry, bead height, stopper design, and coating thickness match the engine builder’s specification. That precision translates into stable sealing stress, minimal relaxation, and predictable compression set across the maintenance cycle. For interfaces adjacent to conical fittings, the dimensional fidelity of SEALING CONE OEM parts—taper angle, seat finish, and hardness—works in tandem with the gasket’s micro-sealing capability, preventing fretting and micro-leaks under pulsating pressure.

Performance benefits are tangible: restored combustion efficiency, consistent boost and exhaust energy to the turbocharger, reduced oil top-up, and accurate cooling performance. Reliability improves because fastener loads and thermal movements are accounted for in the original design stack. From a budget perspective, fewer reworks, shorter downtimes, and longer intervals between overhauls reduce total cost of ownership. Service life is extended by materials that resist creep, hot-gas erosion, and chemical attack, helping the engine maintain specification performance over thousands of operating hours.

MOPA: fast, secure supply of OEM spare parts Gaskets for diesel and gas engines

MOPA is an experienced and reliable partner for OEM spare parts Gaskets across leading diesel and gas engine platforms. We focus on speed, quality, and security in the trade of OEM parts, supporting shipowners, power operators, and service companies with short lead times and technically correct selections. Our team cross-references by engine type and part number, supplies documentation and batch traceability on request, and consolidates deliveries to cut vessel or plant downtime. From MLS head gaskets and exhaust joints to injector seat washers and SEALING CONE marine engine connectors, MOPA streamlines sourcing with consistent quality and careful packaging for long-distance logistics.

Conclusion: Gaskets and SEALING CONE performance in focus

Gaskets are essential to engine integrity, safeguarding compression, fluids, and emissions while stabilizing performance under harsh thermal and mechanical loads. Pairing them with correctly specified SEALING CONE diesel engine interfaces and choosing OEM spare parts suitable for Gaskets delivers dependable sealing, longer service life, and better overall economics.