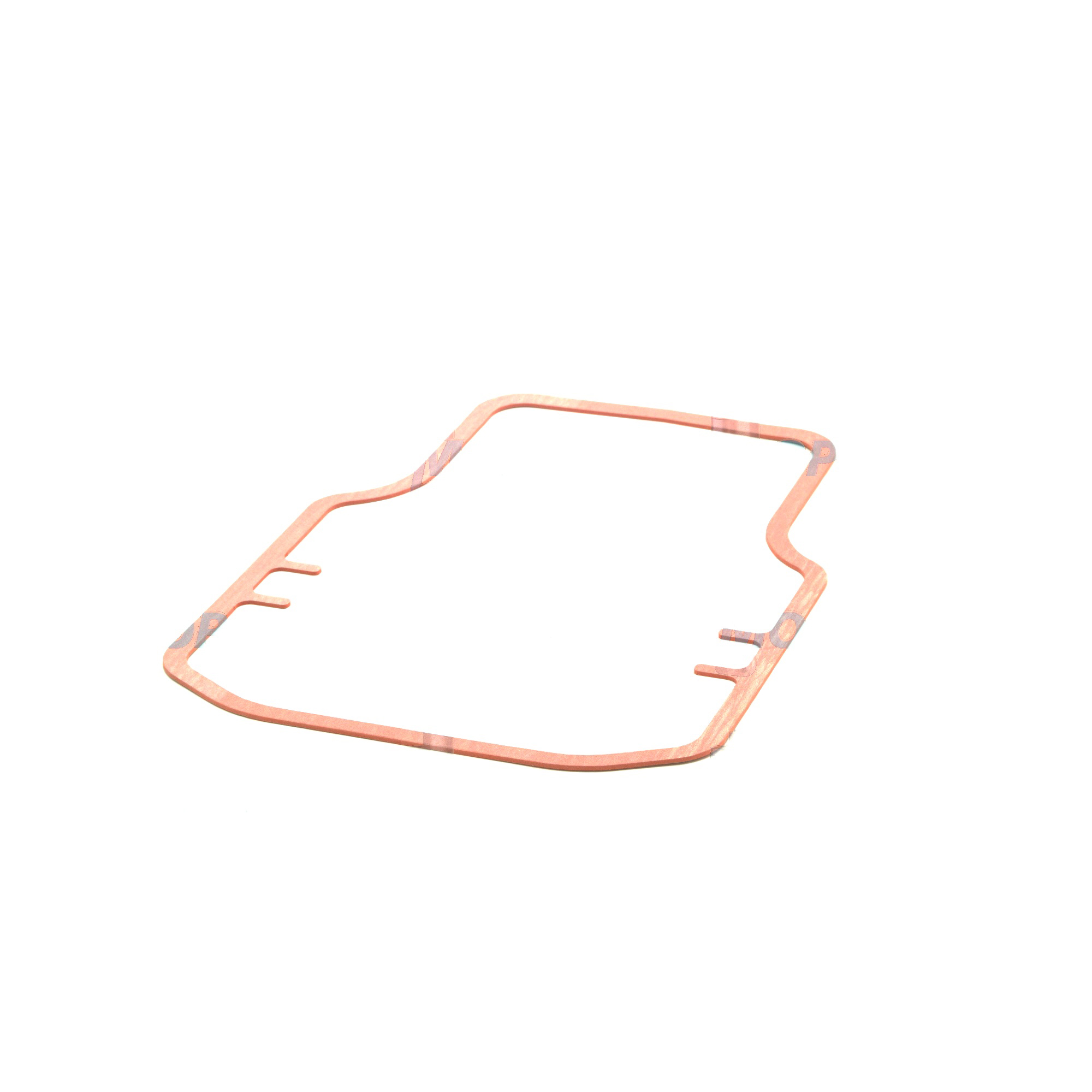

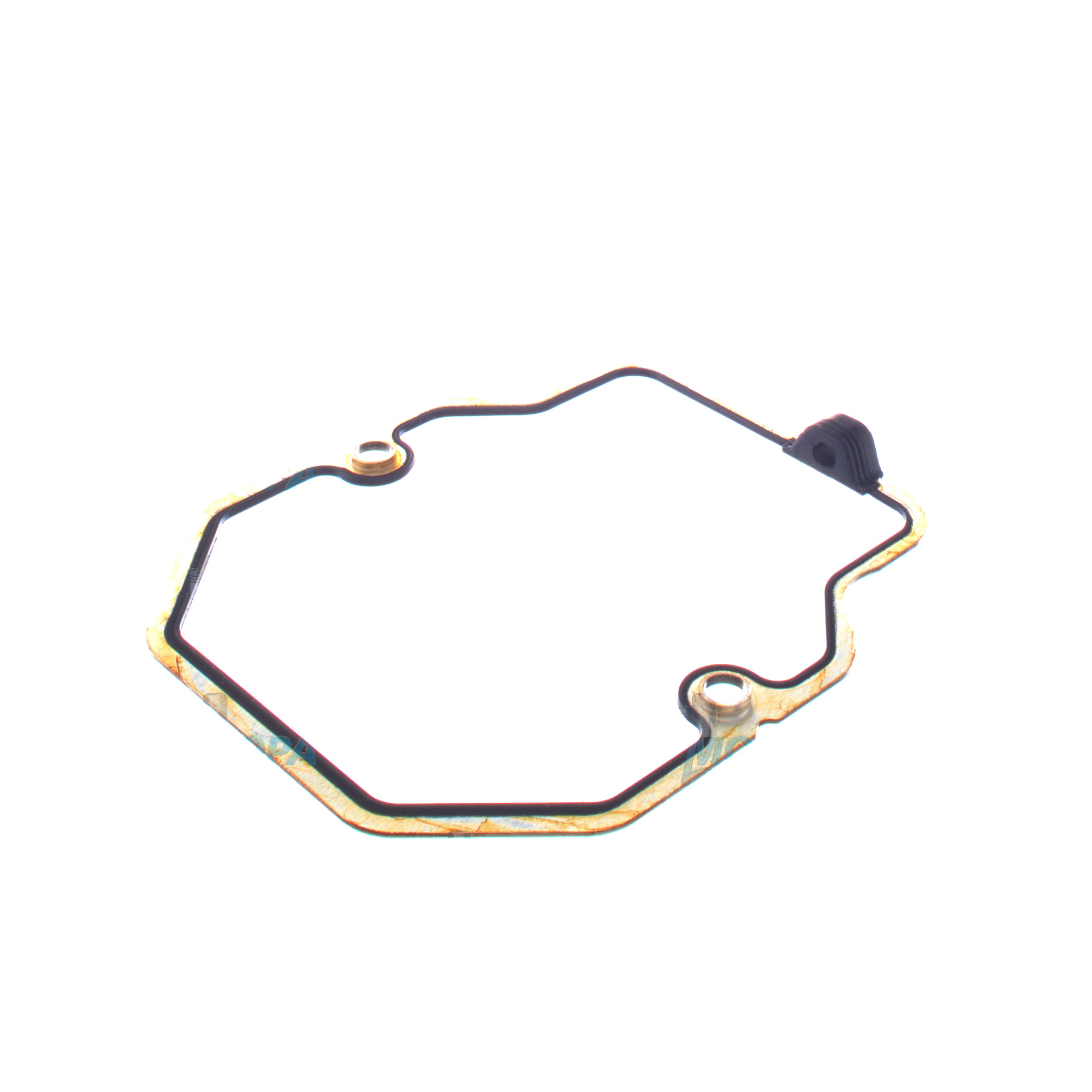

VALVE HOUSING GASKET: Gaskets for high-performance diesel and marine engines

Gaskets are precision-engineered sealing elements that create reliable, leak-free joints between engine components exposed to pressure, temperature, vibration, fuel, oil, and coolant. As a core article category, Gaskets include everything from cylinder head and exhaust flange seals to fuel system and the highly stressed VALVE HOUSING GASKET. In every diesel or gas engine, these parts protect performance by keeping media separated, stabilizing pressures, and preventing contamination across systems.

Within medium- and high-speed diesel engines—common in marine propulsion, auxiliary gensets, power plants, and heavy industry—gaskets are pivotal for efficiency and safety. The VALVE HOUSING GASKET in particular protects the interface around the valve assembly, whether in a rocker/valvetrain cover on smaller units or exhaust valve housings on large-bore marine engines. Robust gasket design and material selection directly affect uptime, emissions compliance, and overall lifecycle cost.

Technical function of Gaskets and VALVE HOUSING GASKET in diesel and marine engines

Gaskets create a micro-seal by conforming to surface irregularities when compressed under controlled bolt loads. Material elasticity, creep resistance, and chemical compatibility must match the operating environment: oil-wet areas often use NBR/FKM elastomers; high-temperature gas paths use graphite or spiral-wound stainless with graphite or PTFE fillers; coolant joints may rely on fiber-reinforced or multi-layer steel constructions. Correct surface finish, torque sequence, and joint design allow the gasket to maintain sealing stress despite thermal cycling and vibration.

The VALVE HOUSING GASKET for a diesel engine typically seals the valve cover or housing against the cylinder head, keeping lubricating oil inside the valvetrain region while preventing air ingress and blow-by gases from escaping. On large marine engine configurations, the VALVE HOUSING GASKET also ensures a gas-tight interface between an exhaust valve housing and the head, containing very hot combustion products and protecting nearby components. In both cases, precise compressibility, thermal resistance, and retention of bolt load are essential. Specifying VALVE HOUSING GASKET OEM parts helps maintain the designed clamping force and sealing line over thousands of operating hours.

By safeguarding pressure boundaries, gaskets stabilize combustion quality, keep turbocharger efficiency high, and protect lubricants and coolants from cross-contamination. A correctly selected VALVE HOUSING GASKET for a marine engine preserves oil cleanliness, limits misting and leakage on deck plates, and supports compliance with safety and environmental standards.

Key characteristics and advantages of Gaskets

· Engineered to match thermal, chemical, and pressure loads.

· Maintain sealing stress despite vibration and cycling.

· Prevent oil, coolant, and gas leakage across interfaces.

· Optimize combustion stability and turbocharger performance.

· Reduce unplanned downtime and maintenance frequency.

· Available in materials such as FKM, NBR, graphite, PTFE, and spiral-wound steel.

· Designed for precise fit and consistent clamping in OEM parts environments.

Why Gaskets, including the VALVE HOUSING GASKET, matter for reliable engine operation

Sealing failures quickly escalate into costly outages. A degraded VALVE HOUSING GASKET can allow oil to leak onto hot surfaces, creating a fire risk, or permit unfiltered air to enter the valvetrain region, accelerating wear. In exhaust interfaces, micro-leaks reduce turbocharger efficiency, raise exhaust temperatures, and compromise emissions control devices. In coolant and fuel connections, leakage can lead to dilution of lubricating oil, bearing damage, or hard starts.

Maintaining tight sealing improves reliability and extends overhaul intervals. Properly functioning gaskets stabilize operating temperatures, protect surface finishes, and preserve correct lubrication regimes. They also help keep the engine room clean and safe, minimize environmental exposure, and support predictable service schedules—critical for shipowners and plant operators running tight voyage or production plans.

Advantages of OEM spare parts suitable for Gaskets and VALVE HOUSING GASKET

Choosing OEM spare parts suitable for gaskets ensures that material composition, geometry, and thickness precisely match the engine builder’s joint design. This fit accuracy translates into consistent bolt load distribution and correct sealing stress, reducing the need for premature retorque and minimizing weep paths. VALVE HOUSING GASKET OEM parts follow validated manufacturing processes and traceable batches, offering dependable performance under high thermal gradients and pressure pulses.

From a budget perspective, high-quality OEM spare parts suitable for gaskets reduce lifecycle cost by lowering leakage-related damage, protecting catalysts and turbochargers, and supporting longer time-between-overhaul targets. They also standardize maintenance procedures, which shortens service times and helps teams avoid errors during reassembly. For safety and compliance, matched materials resist fuel, oil additives, and coolant chemistries, preserving sealing integrity across the full duty cycle.

MOPA: an experienced partner for OEM spare parts Gaskets and VALVE HOUSING GASKET

MOPA supplies OEM parts for diesel and gas engines with an emphasis on speed, quality, and security in every transaction. Our team sources and delivers VALVE HOUSING GASKET solutions and broader gasket sets with short lead times, clear documentation, and reliable logistics—reducing your vessel or plant downtime. We focus on consistent quality, ensuring that the materials and dimensions align with engine specifications across marine propulsion, auxiliary gensets, and industrial power applications.

Fast delivery, technical diligence, and secure trade of OEM parts

With MOPA, purchasers and technical decision-makers gain a responsive partner who understands sealing technology and its operational implications. We support correct part identification, provide kitting for overhauls, and help align gasket choices with temperature, pressure, and media requirements. Our processes prioritize secure sourcing, traceability, and dependable supply so that your engines return to service quickly and stay there.

Conclusion: VALVE HOUSING GASKET and Gaskets safeguard engine efficiency and uptime

Gaskets—especially the VALVE HOUSING GASKET—are essential to engine performance, safety, and longevity by ensuring tight, durable seals under demanding conditions. Selecting OEM spare parts suitable for gaskets preserves designed clamping forces, resists harsh media, and reduces lifecycle costs through dependable, long-term sealing performance.