OIL PRESSURE GAUGE in Gauges and Sensors for Professional Engine Monitoring

Gauges and sensors are the nerve system of industrial, marine, and power-generation engines. They translate physical conditions such as pressure, temperature, speed, and level into readable values and control signals. In doing so, they protect critical assemblies, support efficient operation, and provide the data needed for safe decision-making. Within this category, the OIL PRESSURE GAUGE stands out as the most immediate indicator of lubrication health, helping crews and operators safeguard bearings, camshafts, and turbochargers in every operating condition.

From heavy-duty diesel engine platforms to high-output marine engine rooms, modern gauges and sensors combine robust mechanical designs with precise electronics. Whether displayed on a panel or streamed to a control system, their accuracy and stability are essential to uptime, fuel economy, and compliance with operational standards. The OIL PRESSURE GAUGE, in particular, gives a fast, unambiguous view of oil system integrity during start-up, load changes, and prolonged service intervals.

Technical Function: How Gauges and Sensors Work with the OIL PRESSURE GAUGE in Diesel and Marine Engines

Gauges and sensors measure variables and convert them into operator-readable values or electrical outputs for automation systems. In lubrication circuits, an OIL PRESSURE GAUGE uses a mechanical Bourdon tube or an electronic pressure transducer to track the pressure in the main oil gallery. Mechanical variants deflect a tube to move a needle over a calibrated dial, while electronic senders use piezoresistive or thin-film elements to output a signal (e.g., 4–20 mA, 0–10 V, or CAN J1939) to panels or engine control units. In a diesel engine, this measurement confirms that the oil pump, filters, and galleries are supplying adequate pressure at cranking, idle, and full load. In a marine engine, the gauge gives bridge and engine-room personnel real-time visibility and can be tied to alarms or shutdown logic.

Across the broader category of gauges and sensors, temperature sensors (coolant, lube-oil, and exhaust gas), pressure sensors (boost, fuel rail, and crankcase), level switches, tachometers, and vibration pickups form a comprehensive instrumentation suite. Together, they enable optimized timing, improved combustion stability, and safer load acceptance. An OIL PRESSURE GAUGE OEM parts setup tuned for the engine’s viscosity range and gallery volumes filters out pulsation, delivers fast response, and resists vibration, ensuring that displayed values and transmitted signals are consistent and actionable.

· High accuracy and repeatability across the operating range.

· Fast response with damping to stabilize pulsating signals.

· Rugged build for shock, vibration, and marine engine environments.

· Corrosion-resistant materials (e.g., stainless steel wetted parts).

· Wide temperature range for engine-room heat and cold starts.

· Sealed enclosures (IP ratings) to resist moisture and oil mist.

· Electrical options: 4–20 mA, 0–10 V, NPN/PNP, or CAN/J1939.

· Clear scales, backlighting, and high-contrast dials for readability.

· Thread and connector compatibility for drop-in integration.

· Calibrated to engine setpoints for reliable alarms and trips.

Why Gauges and Sensors Are Critical for Engine Reliability and Service Life

Reliable instrumentation protects machinery. If an OIL PRESSURE GAUGE reads correctly, operators can confirm immediate oil pressure rise on start, verify stable pressure under load, and detect anomalies such as filter blockage, pump wear, or oil foaming. Conversely, inaccurate or drifting gauges and sensors can mask low oil pressure, causing bearing starvation, scuffing, and turbocharger failure—often within minutes. Likewise, misreading coolant temperature or exhaust gas temperature leads to overheating, detonation risk, or unnecessary derating.

Faulty or mismatched sensors also create nuisance trips, costly downtime, and misdiagnosed faults. Over time, contamination, vibration, and thermal cycling may cause signal drift. That is why the condition of gauges and sensors directly influences maintenance decisions, from oil change intervals to overhaul timing. High-quality OIL PRESSURE GAUGE assemblies and matched senders stabilize readings, improve trend analysis, and support condition-based maintenance programs that extend component life and reduce lifecycle cost.

Advantages of OEM Spare Parts Suitable for Gauges and Sensors

Specifying OEM spare parts suitable for gauges and sensors ensures dimensional accuracy, signal integrity, and calibration that matches engine logic. For an OIL PRESSURE GAUGE or its sender, correct scaling, damping, and hysteresis are essential so alarms trigger at precisely the intended thresholds. The right materials resist sulfur, fuel dilution, and seawater exposure. The correct electrical interface prevents noise and false readings in high-EMI environments typical of large diesel engine installations.

From a performance perspective, precise instrumentation supports better fuel efficiency by maintaining stable operating conditions and enabling timely corrective actions. From a reliability and budget standpoint, sensors and gauges that fit correctly and communicate flawlessly reduce troubleshooting time, prevent unnecessary part replacements, and minimize unplanned outages. The result is consistent performance, longer service life of rotating assemblies, and clearer maintenance planning—benefits that far outweigh any short-term saving from mismatched components.

· Drop-in fit with the right threads, connectors, and pinouts.

· Calibrated scaling that aligns with ECU and panel setpoints.

· Proven resistance to vibration, heat, and contaminants.

· Strong signal quality and EMC compliance for clean data.

· Documentation and traceability for safe operation and audits.

· Lower downtime and predictable total cost of ownership.

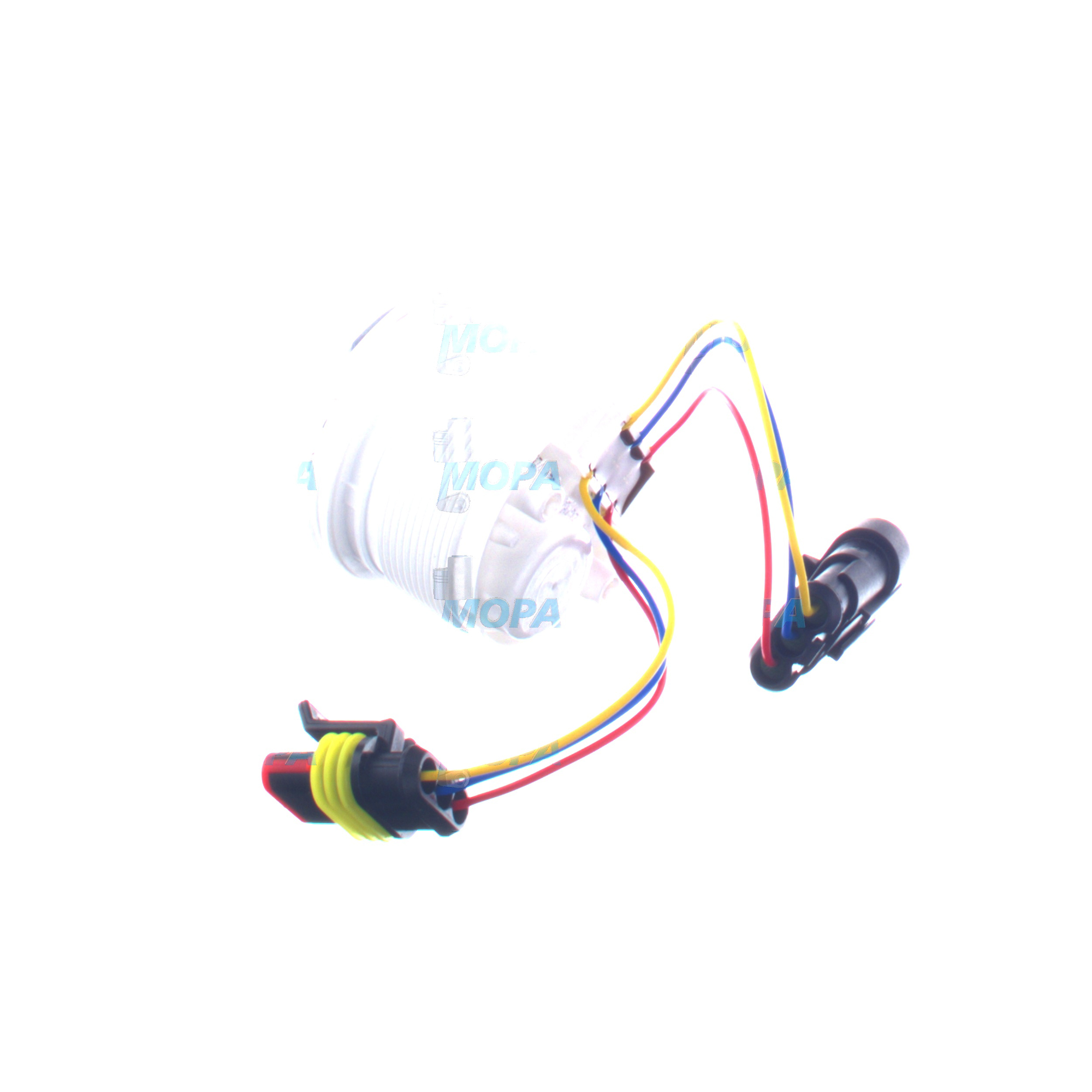

MOPA: Fast, Secure Supply of OEM Parts for Gauges and Sensors

MOPA is an experienced partner for OEM spare parts suitable for Gauges and sensors, including OIL PRESSURE GAUGE solutions for diesel and gas engines. We prioritize speed, quality, and security in every transaction—backed by technical know-how and rigorous part identification. Whether you need panel gauges, electronic senders, temperature probes, pressure transducers, or level switches, MOPA sources precisely matched components and ships quickly to minimize downtime.

Our team supports purchasers, shipowners, and technical decision-makers with clear documentation, reliable lead times, and responsive service. With MOPA, you gain a single point of contact for compliant, engine-ready instrumentation that integrates seamlessly and performs under harsh operating conditions.

Conclusion: OIL PRESSURE GAUGE and Gauges and Sensors Matter

An accurate OIL PRESSURE GAUGE is the front line of protection for any diesel engine or marine engine, and it sits within a critical ecosystem of gauges and sensors that keep equipment safe and efficient. Choosing OEM spare parts suitable for Gauges and sensors ensures precise fit, clean signals, and dependable calibration—delivering stable performance, longer service life, and better budget control.