PRESSURE TRANSMITTER Gauges and Sensors for Marine and Diesel Engines

Gauges and sensors form the measurement backbone of any propulsion or power-generation system. This article category covers the devices that capture critical variables—pressure, temperature, level, flow, and speed—and convert them into readable values or electrical signals for the control system and crew. In heavy-duty applications such as a marine engine or high-output diesel engine, the PRESSURE TRANSMITTER is the central element for monitoring lubrication oil, fuel rail, boost/scavenge air, and cooling circuits. Together with complementary gauges and sensors, it enables safe start-up, stable operation, optimal fuel efficiency, and timely protection against abnormal conditions.

Modern engine management depends on robust sensing. Whether the signal is displayed on a bridge gauge, sent to a local panel, or transmitted to an ECU via analog or CAN bus, the integrity of gauges and sensors directly dictates decision quality—by operators, by automation, and by remote monitoring systems. Selecting and maintaining the right PRESSURE TRANSMITTER and associated instruments is therefore a direct lever on performance, uptime, and lifecycle cost.

Technical function of Gauges and Sensors and the PRESSURE TRANSMITTER in a marine engine

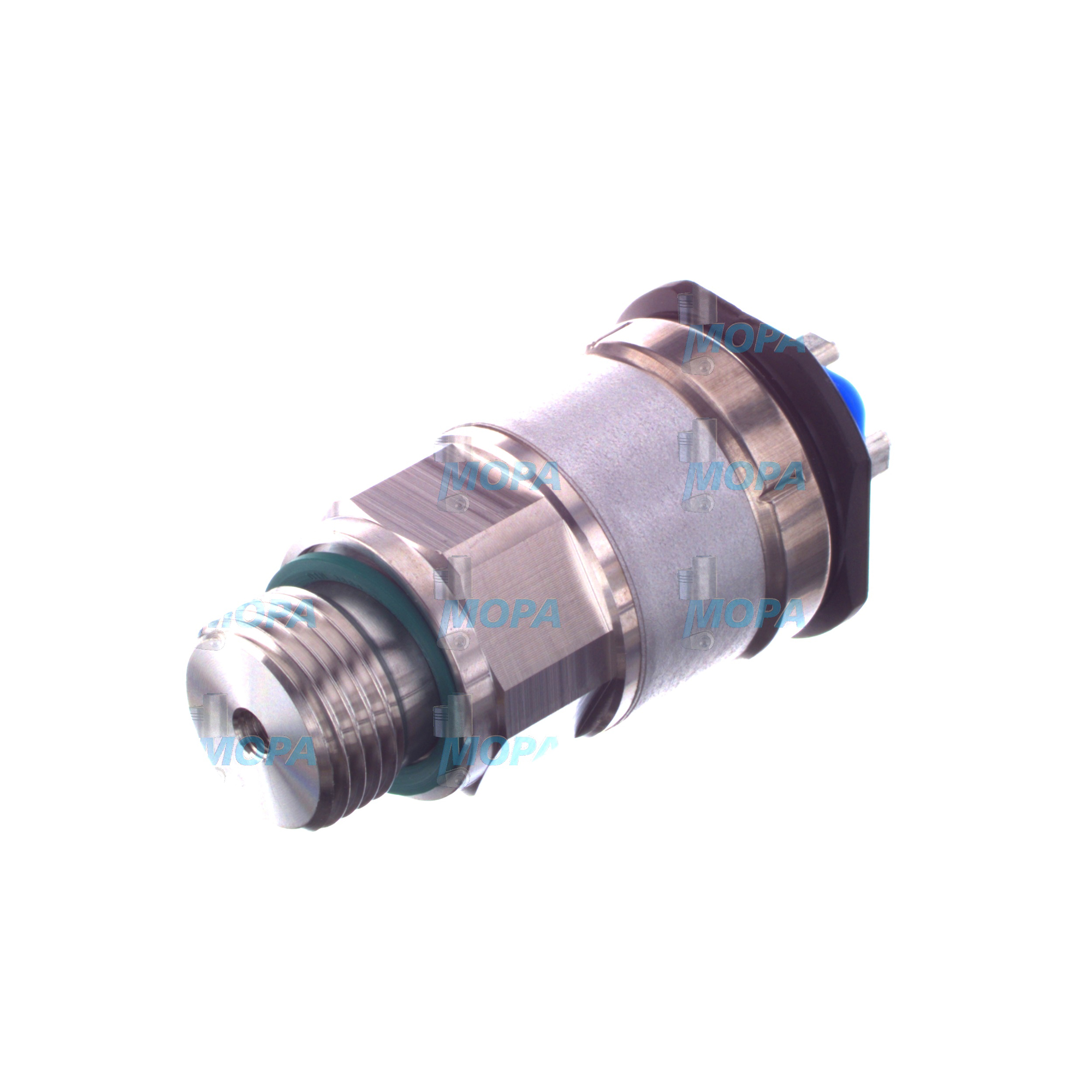

At the heart of engine monitoring, a PRESSURE TRANSMITTER for a marine engine converts the mechanical pressure of a process medium (lube oil, diesel fuel, coolant, charge air) into an electrical output. Common transduction technologies include piezoresistive silicon, thin-film strain gauge on stainless steel, and ceramic capacitive diaphragms. These elements deform under pressure; the resulting resistance or capacitance change is conditioned by onboard electronics to produce standardized outputs (typically 4–20 mA, 0–10 V, or ratiometric 0.5–4.5 V). In digital environments, the signal may be provided over CAN J1939 or proprietary CAN protocols, simplifying integration with engine controllers and vessel monitoring systems.

The PRESSURE TRANSMITTER diesel engine configuration is typically specified by range (e.g., 0–10 bar for lube oil, 0–400 bar for common-rail fuel), process connection (G1/4, 1/4" NPT, M10x1), wetted materials (316L stainless, Hastelloy for corrosive media), electrical interface (M12, Deutsch DT04, AMP Superseal), response time, and accuracy (e.g., ±0.5% FS including hysteresis and repeatability). Rugged designs meet high shock and vibration levels per marine standards, with ingress protection up to IP67/IP69K and wide operating temperatures (e.g., −40 to +125 °C). These attributes ensure stable readings despite engine-induced vibration, salt-laden atmospheres, and thermal cycling.

From PRESSURE TRANSMITTER to ECU: signal flow and control

Transmitter outputs feed the engine control unit, where values are scaled and validated. The ECU then drives closed-loop functions—fuel metering, wastegate or VGT actuation, cooling pump speed, and safety logic (alarms/trips). Gauges (analog or digital) mirror these values for local situational awareness. High fidelity in gauges and sensors allows finer control targets, such as tighter oil-pressure margins and more precise load-sharing on generator sets, which boosts efficiency and reduces wear.

Key characteristics of Gauges and Sensors

- · Real-time, stable measurement under vibration and thermal shock.

- · Standardized outputs (4–20 mA, 0–10 V, CAN) for straightforward integration.

- · Corrosion-resistant wetted parts for fuel, oil, water, and seawater.

- · Fast response for protection functions and trip thresholds.

- · Tight accuracy and low drift for reliable trending and diagnostics.

- · Marine-grade connectors and seals to maintain signal integrity.

Importance for engine operation: why gauges and sensors, including the PRESSURE TRANSMITTER in a diesel engine, matter

Engine reliability depends on precise and timely measurements. If a PRESSURE TRANSMITTER drifts or a temperature probe becomes sluggish, the control system may react late or incorrectly. Consequences range from nuisance alarms and unnecessary slowdowns to severe failures: bearing damage due to undetected low oil pressure, turbocharger overspeed from misread boost pressure, injector scuffing from unstable fuel rail pressure, or thermal stress from inaccurate coolant readings. Over time, even minor sensor bias inflates fuel consumption, undermines emissions compliance, and masks early warning signs in condition-based maintenance.

Typical failure modes include diaphragm fatigue, clogging of pressure ports by varnish or debris, moisture ingress into connectors, cable breaks, and calibration drift after prolonged high-temperature exposure. Best practice includes periodic verification against a reference, inspection and cleaning of pressure tappings, correct routing and strain relief for harnesses, and timely replacement at specified intervals. Using calibrated gauges and sensors with known drift characteristics keeps trend lines trustworthy, enabling proactive maintenance rather than reactive downtime.

Advantages of OEM spare parts for Gauges and Sensors and the PRESSURE TRANSMITTER OEM parts

OEM spare parts suitable for gauges and sensors align precisely with engine control strategies, scaling factors, and mechanical interfaces. That compatibility reduces commissioning time, eliminates ad‑hoc parameter edits in the ECU, and preserves the designed protection margins. A PRESSURE TRANSMITTER OEM parts selection ensures the correct electrical pinout, proper damping to avoid pulsation-induced oscillation, and materials matched to diesel fuel additives or high‑temperature lubricants.

From a reliability and budget perspective, the long-term stability and documented performance of OEM spare parts extend service intervals and reduce false trips, which directly lowers total cost of ownership. Their validated shock/vibration resistance and ingress protection ratings sustain measurement integrity in harsh marine spaces. For service life, consistent drift behavior and available calibration data make lifecycle planning and audits straightforward—especially important for class approvals and environmental compliance.

- · Exact fit for threads, seals, and connectors—no adapters needed.

- · Calibration curves and scaling match ECU expectations.

- · Proven durability under engine vibration and temperature extremes.

- · Stable signals reduce nuisance alarms and unplanned stoppages.

- · Lower installation time and risk through plug‑and‑play compatibility.

- · Transparent documentation supports maintenance and compliance.

MOPA: fast, high-quality, and secure supply of OEM parts for Gauges and Sensors

MOPA is an experienced and reliable partner for OEM spare parts in the Gauges and sensors category, including every major type of PRESSURE TRANSMITTER for diesel and gas engines. Our team sources through a traceable network and provides rapid quotations, precise cross-referencing to engine models, and documentation on request. We focus on speed—global dispatch for critical spares—while maintaining quality through inspected goods, controlled storage, and robust packaging suitable for marine logistics.

Security in trade means you receive exactly the specified component: correct pressure range, connector, output type, and material configuration, minimizing installation risk and downtime. Whether you need a PRESSURE TRANSMITTER marine engine configuration for lube oil, a high-pressure unit for common-rail diesel systems, or matching gauges for local panels, MOPA streamlines the process so your vessel or plant returns to service quickly and confidently.

Conclusion: PRESSURE TRANSMITTER Gauges and Sensors

Gauges and sensors—led by the PRESSURE TRANSMITTER—are essential for safe, efficient, and compliant operation of marine and diesel engines. Selecting calibrated, engine-matched OEM spare parts preserves measurement accuracy, protects critical assets, and optimizes lifecycle cost. With MOPA as your partner, you gain fast, secure access to the right components that keep performance and reliability on spec.