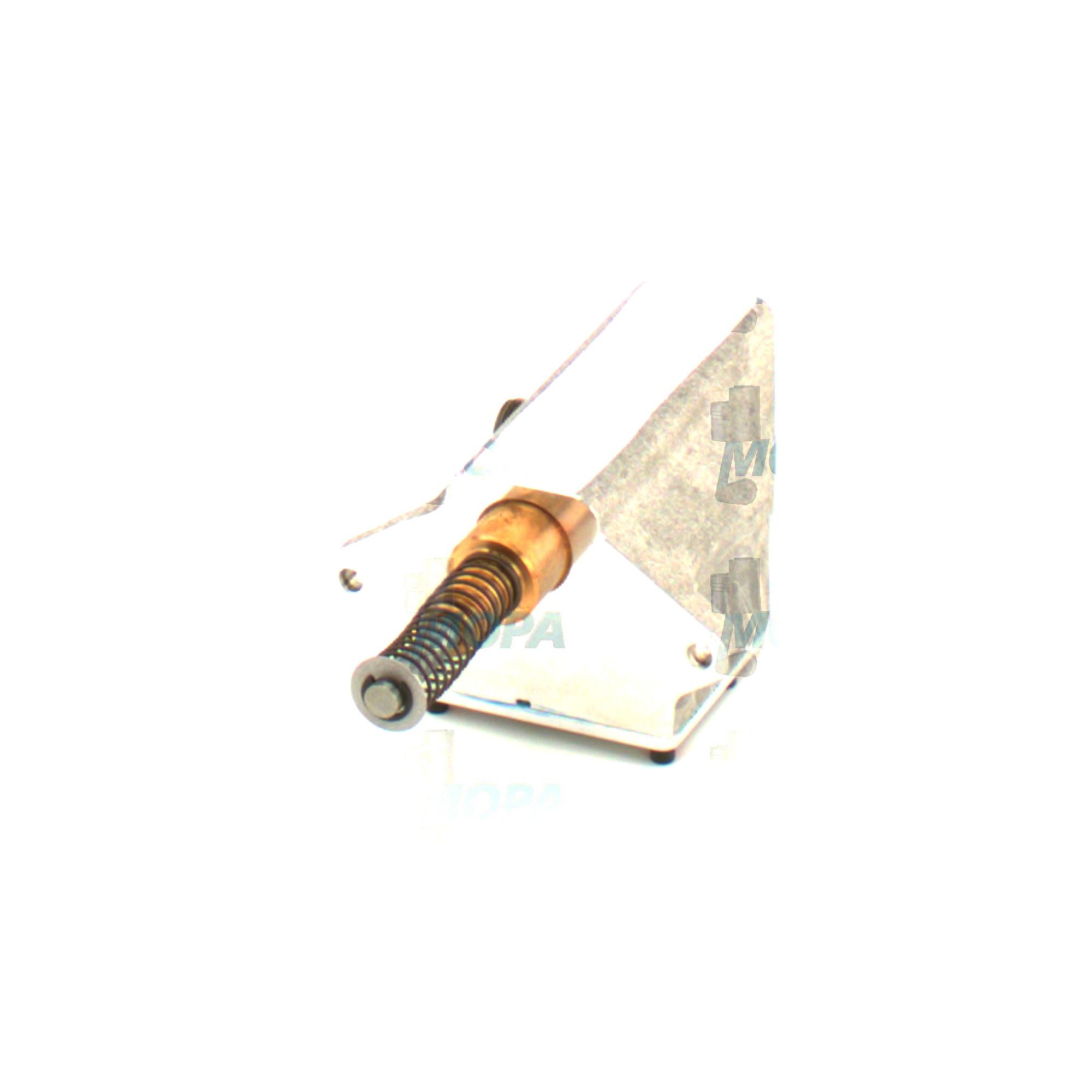

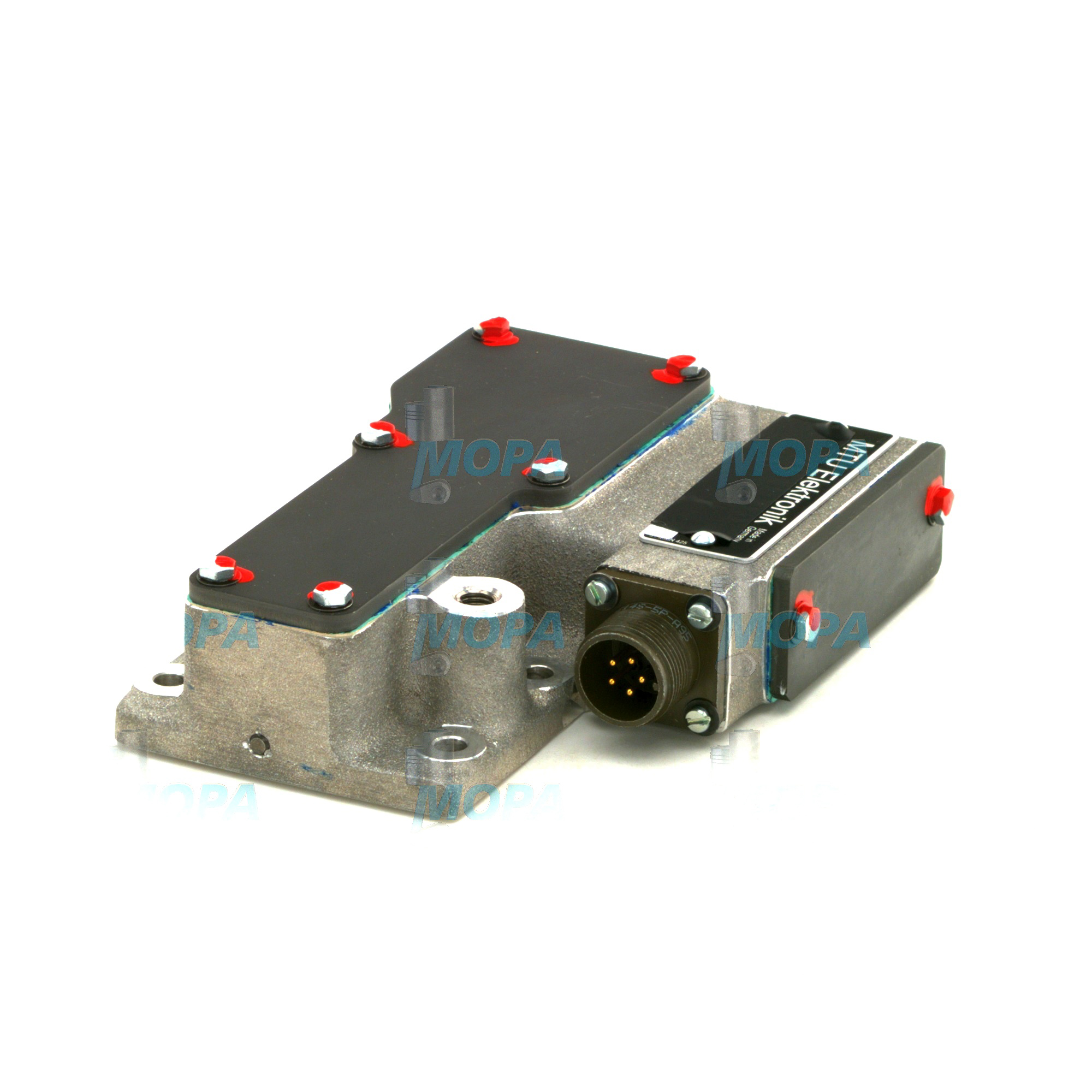

TRAVEL SENSOR in Gauges and Sensors for Marine and Diesel Engines

Gauges and sensors are the nerve system of every propulsion and power-generation unit. Within this article category, you will find devices that measure, display, and transmit critical operating data—pressure, temperature, level, flow, speed, and linear position—to keep engines efficient and safe. In marine engines and stationary diesel or gas engines, this instrumentation enables precise control, early fault detection, and traceable performance oversight. From classic dial gauges to digital transmitters and position feedback devices such as a TRAVEL SENSOR, these components convert real-world conditions into actionable signals for engine controls and crew.

Technical function of Gauges and Sensors and the role of the TRAVEL SENSOR

Gauges provide at-a-glance values for operators, while sensors feed measured signals to the engine control unit (ECU), governor, or safety system. Together, they form a closed loop that manages fuel delivery, charge air, lubrication, and cooling. A TRAVEL SENSOR in a diesel engine or marine engine is a linear position transducer that reports the exact stroke or displacement of moving parts—commonly the fuel rack, actuator rod, VGT nozzle ring, or throttle linkage. Its precise feedback supports smooth load changes, accurate fuel metering, and reliable synchronization on multi-engine setups.

In practice, the TRAVEL SENSOR converts mechanical motion into an electrical output (e.g., 4–20 mA, voltage, or digital bus), allowing the controller to compare commanded vs. actual positions. This minimizes hunting, reduces overshoot in transient conditions, and stabilizes emissions and fuel burn. Across the wider category, pressure and temperature sensors protect bearings and liners, speed sensors ensure correct governor action, and level sensors safeguard lubrication and cooling margins. Properly specified OEM parts sustain calibration stability, electromagnetic compatibility, and durability under vibration, salt-laden air, and thermal cycling—conditions typical in engine rooms and machinery spaces.

Key characteristics and advantages of Gauges and sensors

· Accurate measurement over wide temperature and vibration ranges.

· Fast response for stable control and protective trips.

· Robust sealing and corrosion-resistant materials for marine duty.

· Calibrated outputs for reliable ECU integration.

· Flexible signals (4–20 mA, CAN bus, Modbus, voltage).

· Built-in diagnostics and fault detection.

· Long service intervals with low drift.

· Clear readability and traceable documentation.

Importance for engine operation: reliability, efficiency, and safety

Gauges and sensors directly determine the reliability and service life of engines. When measurement is correct, the control system keeps the engine within design limits: cylinder temperatures stay balanced, oil pressure and flow remain adequate, and fuel delivery matches load without excessive smoke or knock. The TRAVEL SENSOR is crucial where linear movement translates into power—fuel rack position in a diesel engine, actuator stroke in turbo machinery, or valve gear displacement in specialized applications. If this signal drifts or fails, the ECU may overfuel, underfuel, or oscillate, causing rough running, slow load acceptance, or even shutdowns.

Problems that arise from worn or mis-specified components include false alarms, missed alarms, excessive thermal stress, turbocharger surge, bearing damage from oil starvation, and emissions non-compliance. In a marine engine, a degraded TRAVEL SENSOR can trigger governor instability, leading to speed fluctuations during maneuvering or synchronization issues on shaft lines—risks that increase fuel consumption, threaten schedules, and complicate port operations. Keeping gauges and sensors in optimum condition isn’t optional; it is central to uptime, class compliance, and lifecycle economics.

Failure modes and what to watch for in Gauges and sensors

Common failure modes include signal drift due to aging, hysteresis in mechanical linkages, connector corrosion, cracked diaphragms in pressure elements, insulation breakdown under heat, and intermittent outputs from cable fatigue. Symptoms often appear as sporadic alarms, unexplained load changes, unstable idle, inaccurate displays, or trip events that do not correlate with actual conditions. Regular verification against reference standards, clean connectors, and timely replacement with correctly calibrated components prevent escalation into costly downtime.

Advantages of OEM spare parts suitable for Gauges and sensors

OEM spare parts suitable for gauges and sensors preserve the intended performance envelope of the engine and its controls. They deliver known signal scaling, precise mechanical fit, and material compatibility with fuels, lubricants, and coolants. For a TRAVEL SENSOR OEM parts configuration, the correct electrical characteristics and stroke length eliminate re-engineering on site, reducing commissioning time and the risk of control-loop instability.

For technical buyers and shipowners, the benefits are clear: consistent measurement accuracy, faster installation, and predictable maintenance planning. Calibrations and test records align with the control strategy authored by the engine maker, supporting repeatable emissions, fuel efficiency, and protection setpoints. Over the life of the asset, this reduces unplanned stoppages, protects major components, and optimizes total cost of ownership.

MOPA: fast, secure supply of OEM parts for Gauges and sensors

MOPA is a reliable partner for OEM spare parts in Gauges and sensors, including the TRAVEL SENSOR for a marine engine or a diesel engine power plant. We prioritize speed, quality, and security in the trade of OEM parts for diesel and gas engines. Our team supports accurate cross-referencing, provides documentation such as test certificates when available, and coordinates end-to-end logistics with marine-grade packaging. With responsive lead times and transparent communication, MOPA helps minimize downtime and keeps propulsion and auxiliary sets operating within specification. Whether you need a TRAVEL SENSOR OEM parts package, pressure transmitters, temperature probes, or display gauges, MOPA streamlines procurement and delivery.

Conclusion: Gauges and sensors with TRAVEL SENSOR focus

Gauges and sensors—especially precise position feedback from a TRAVEL SENSOR—are fundamental to safe, efficient, and predictable engine operation. Selecting OEM spare parts suitable for this category preserves measurement integrity, stabilizes control loops, and extends the service life of diesel and gas engines while protecting your budget through fewer disturbances and faster commissioning.