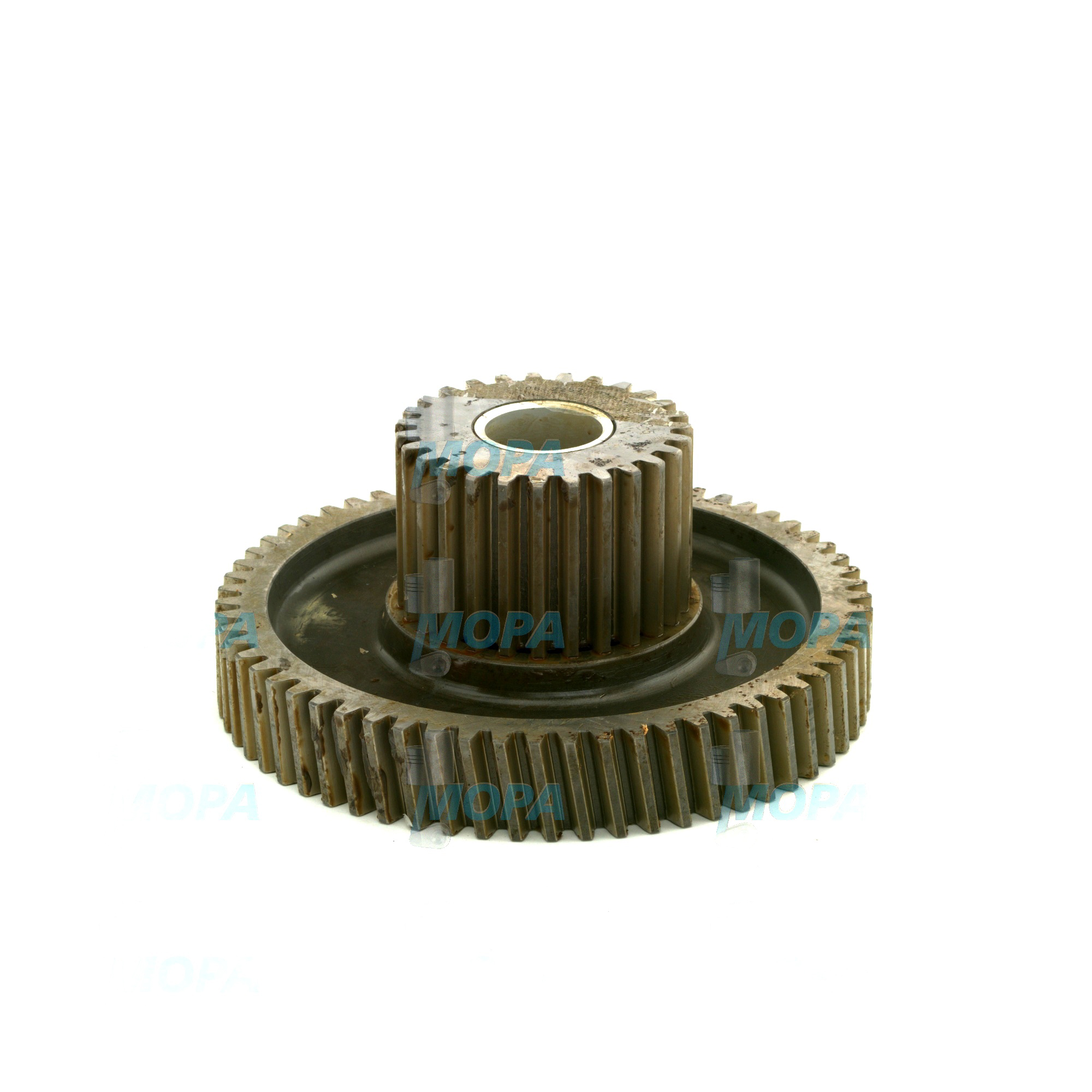

IDLER GEAR for Gears and Toothed Wheels in Marine and Diesel Engines

Gears and toothed wheels are precision power‑transmission components that coordinate motion and torque throughout an engine. From timing the camshaft to driving fuel injection equipment and auxiliaries, these parts convert crankshaft rotation into accurately controlled speeds and directions. Within this system, the IDLER GEAR is a pivotal element that redirects rotation and bridges center distances without changing gear ratios, enabling compact layouts in high‑power diesel and gas engines. For shipowners, operators, and plant managers, dependable gear trains are fundamental to stable output, clean combustion, and predictable maintenance cycles.

As an article category, gears and toothed wheels include spur, helical, and bevel designs made from alloy steels, typically case‑hardened and ground to tight tolerances. Their tooth geometry—module or DP, pressure angle, helix angle, and lead—must be precisely matched across the train to ensure correct backlash and load distribution. In marine engine rooms and power plants alike, these components work under continuous load, fluctuating temperatures, and stringent noise and vibration targets. Proper selection and upkeep directly influence efficiency, emissions compliance, and service life.

Technical Function of Gears and Toothed Wheels with IDLER GEAR in a Diesel Engine

In a diesel engine, the gear train transmits crankshaft motion to the camshaft, fuel injection pump(s), balance shafts, and auxiliary drives (e.g., lube oil and high‑pressure pumps). The IDLER GEAR in a diesel engine serves three essential roles: it reverses rotation when required, adjusts shaft center distances to fit the engine layout, and distributes torque paths to multiple driven components. In many large‑bore marine engines, the timing case includes one or more idlers that stabilize load sharing between the crank gear and cam gear while also driving governors or hydraulic pumps.

Functionally, gears and toothed wheels rely on a hardened case and finely finished tooth flanks to transfer load with minimal friction and noise. Correct backlash is critical—too little raises temperature and scuffing risk; too much increases impact loading, accelerates pitting, and degrades timing accuracy. Lubrication regimes—splash or forced—must maintain an oil film robust enough to separate tooth surfaces under peak torque. Filtration quality (often monitored to ISO cleanliness levels) further protects tooth flanks and bearings from abrasive wear. In addition, tooth profile and lead modifications compensate for deflection and thermal growth at operating temperature to keep contact in the optimal zone.

In marine engine timing systems, an IDLER GEAR for a marine engine enables flexible accessory placement and helps keep overall engine length within platform constraints. When specified as IDLER GEAR OEM parts, the gear’s tooth profile, case depth, and core toughness align with the mating gears, preserving the designed contact pattern. This compatibility reduces NVH, maintains injection timing, and protects camshaft followers from overload events during starting, reversing, and rapid load changes.

- · Precise torque transmission under continuous load

- · Stable timing for camshaft and injection equipment

- · Optimized backlash for low noise and reduced wear

- · Case‑hardened and ground tooth flanks for durability

- · IDLER GEAR enables compact layouts and rotation reversal

- · Consistent performance in marine and stationary power applications

Importance for Engine Operation and Service Life of Gears and Toothed Wheels

Reliability of gears and toothed wheels directly determines whether an engine meets power, emissions, and availability targets. A worn or misaligned IDLER GEAR compromises valve timing and injection events, increasing fuel consumption and smoke while elevating bearing and follower loads. Typical failure modes include micropitting, macropitting, scuffing, tooth flank fatigue, and tooth root cracking—often accelerated by incorrect hardness, poor lubrication, contamination, or mismatched geometries. Excessive backlash can cause timing scatter, gear hammer, and elevated vibration, while insufficient backlash leads to heat build‑up and scuffing during transient load steps.

If this category of components is not maintained to specification, operators can expect reduced efficiency, rising oil temperatures, metal debris in the lube system, and unplanned shutdowns. For marine propulsion, that risk translates into schedule disruptions and class inspection findings. Proactive condition monitoring—contact pattern checks, backlash measurement, oil analysis, and endplay verification—combined with timely replacement using correctly matched parts sustains long intervals between overhauls and protects the entire valve train.

Advantages of OEM Spare Parts Suitable for Gears and Toothed Wheels

Using OEM spare parts suitable for gears and toothed wheels ensures dimensional fidelity, material chemistry, and heat‑treatment profiles that match the original design intent of the engine builder. That fidelity is especially crucial for the IDLER GEAR, where tooth profile accuracy and case depth must align with the mating set to maintain the engineered contact pattern. With OEM parts, compatibility extends beyond geometry to include microstructure, residual stress distribution, and surface finish, yielding predictable durability under cyclic loads.

From a performance and budget standpoint, these parts help keep vibration and noise within expected bounds, sustain injection timing stability, and minimize collateral wear on shafts and bearings. Documented production routes, batch traceability, and test routines provide confidence for critical diesel and gas engines in marine propulsion and power generation. Over the lifecycle, the result is lower total cost of ownership through reduced downtime, fewer corrective interventions, and consistent intervals between major overhauls.

- · Exact fit and tooth geometry for the specific engine model

- · Verified metallurgy, case hardening, and flank finish

- · Stable timing, lower NVH, and improved efficiency

- · Reduced risk of pitting, scuffing, and root cracking

- · Predictable lifecycle and optimized maintenance planning

- · Strong value for budget control and uptime

MOPA – Your Partner for OEM Parts: Gears and Toothed Wheels with IDLER GEAR

MOPA is an experienced, reliable partner for OEM spare parts suitable for gears and toothed wheels, including the IDLER GEAR for marine engine and diesel engine applications. We prioritize speed in sourcing and logistics, consistent quality across all deliveries, and security in the trade of OEM parts for diesel and gas engines. Our team supports you with technical clarification, part identification by engine type and serial, and fast supply to keep your asset in service with minimal downtime.

Conclusion: IDLER GEAR and Gears and Toothed Wheels

Gears and toothed wheels—especially the IDLER GEAR—are central to timing accuracy, reliability, and efficiency in marine and diesel engines. Selecting OEM spare parts suitable for this category preserves designed contact patterns and performance, extending service life while protecting your maintenance budget.