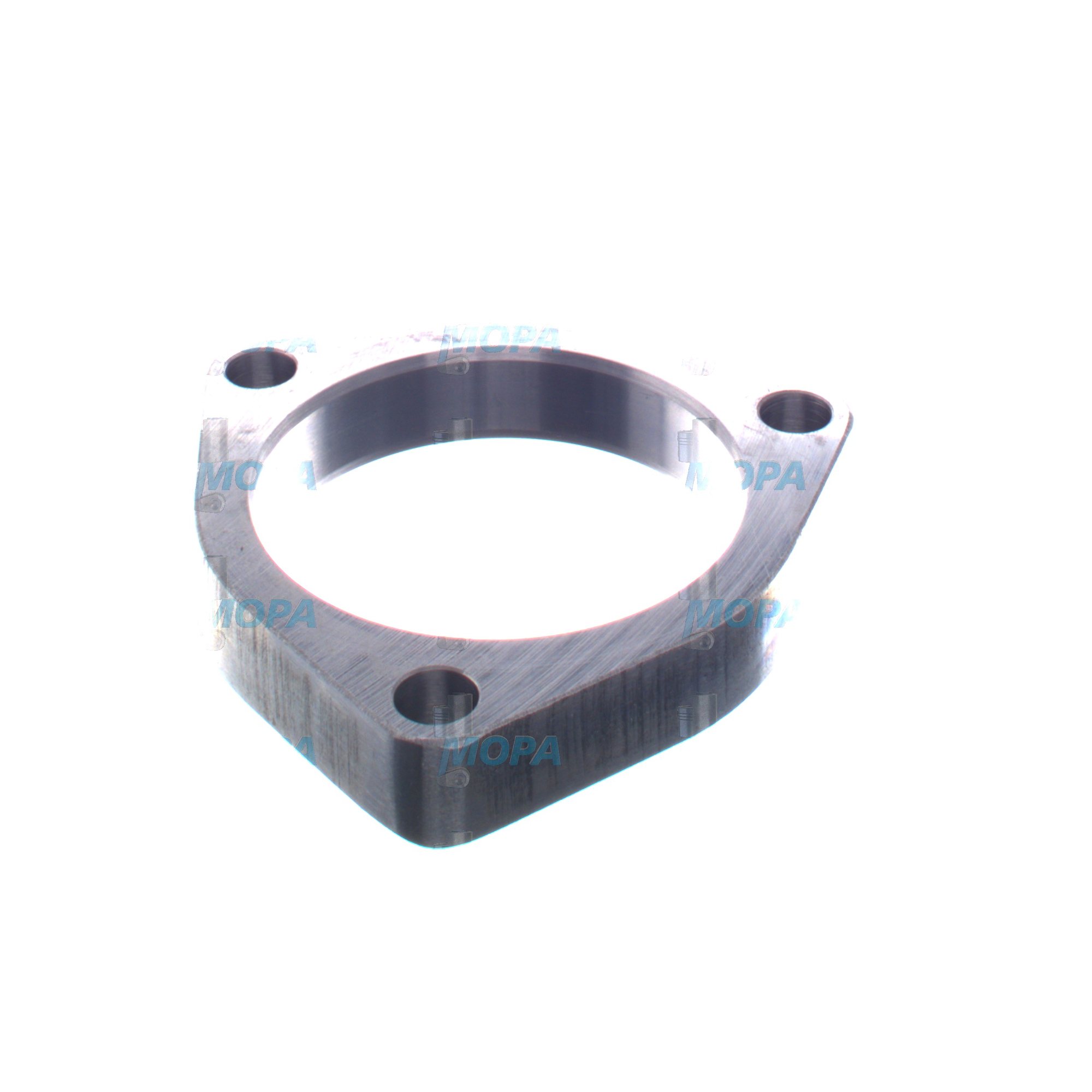

PLUG-IN FLANGE holders, plates and flanges

Holders, plates and flanges form the mechanical backbone of an engine’s auxiliary systems. From securing pumps, filters, heat exchangers and sensors to creating leak-tight junctions in fuel, lube oil, cooling water, air and exhaust lines, these components provide structural support, precise alignment and reliable sealing under demanding operating conditions. In heavy-duty diesel and gas applications—especially in marine engine rooms—robust holders prevent component drift, plates distribute loads and maintain geometry, and flanges, including the PLUG-IN FLANGE variant, enable fast, safe connections with repeatable accuracy.

Technical function of PLUG-IN FLANGE holders, plates and flanges in diesel and marine engines

In a diesel engine or marine engine installation, holders keep accessories rigidly fixed to the block, bedplate or skids while isolating vibration and preserving alignment. Mounting plates act as interface elements: they spread mechanical loads, maintain flatness, and ensure parallelism between mating faces. Flanges—particularly the PLUG-IN FLANGE—serve as precision couplings that align pipework and equipment nozzles, seal process media, and allow quick disconnection during service. A PLUG-IN FLANGE marine engine connection, for example, provides a guided, self-centering fit with controlled tolerances that safeguard concentricity, reduce assembly time, and minimize leak paths.

Engineering details matter. Properly machined faces (e.g., controlled Ra surface finish) and groove geometry for O-rings or spiral-wound gaskets deliver reliable sealing under thermal cycling and pressure pulsations. Dowel pins and pilot diameters maintain positional accuracy, while high-strength fasteners and defined torque procedures keep joints stable under vibration. Materials range from carbon and alloy steels to stainless and duplex grades for corrosion-prone environments; protective coatings such as zinc-nickel or epoxy systems add additional defense against salt-laden atmospheres. Pressure classes frequently align with EN 1092-1/ISO 7005 or ASME B16.5 ranges, while dimensional fits are specified to OEM parts drawings so that the PLUG-IN FLANGE OEM parts integrate seamlessly with mating components.

- · High positional accuracy for shafts, pumps, and pipework.

- · Leak-tight sealing faces for fuel, lube oil, cooling water, air and exhaust.

- · Vibration resistance through rigid holders and optimized fasteners.

- · Corrosion protection via material selection and coatings.

- · Quick serviceability with PLUG-IN FLANGE guided connections.

- · Load distribution and flatness control using engineered plates.

- · Compatibility with common pressure classes and gasket standards.

- · Traceability and documented material certificates for quality control.

Importance for engine operation and lifecycle

Holders, plates and flanges are mission-critical for uptime. Misaligned plates can transfer eccentric loads into pumps and couplings, accelerating bearing wear and causing vibration. Incorrectly machined or damaged PLUG-IN FLANGE faces lead to micro-leaks, pressure loss, or contamination ingress—issues that can escalate to overheating, fuel dilution of oil, or loss of lubrication. Corroded flanges or fatigued bolt sets compromise joint integrity, while insufficient bracketing may allow resonances to amplify, loosening connections and risking failures of sensors, filters or coolers. In a diesel engine, even small deviations in alignment or sealing can increase fuel consumption, degrade emissions performance, and shorten component life. Ensuring these parts remain within specification protects both performance and safety.

Advantages of OEM spare parts suitable for holders, plates and flanges

For precise interfaces like a PLUG-IN FLANGE diesel engine connection, adherence to dimensional tolerances is essential. OEM spare parts suitable for holders, plates and flanges are produced to the drawings, materials and process controls defined for the engine platform. This consistency ensures the joint geometry, bolt patterns, surface finishes and gasket grooves match the mating components exactly. The result is predictable sealing behavior, faster installation, and reduced risk of rework or leakage after commissioning.

Beyond fit, OEM spare parts help optimize total cost of ownership. Certified metallurgy and heat treatment deliver the strength and toughness needed to withstand pulsation and shock loads. Surface protection systems are matched to operating environments, which slows corrosion and extends service intervals. Documented quality (e.g., inspection reports, dimensional checks and mill certificates) supports class compliance and auditability—critical in marine and power generation contexts. In short, PLUG-IN FLANGE OEM parts and their matching holders and plates reduce downtime risk, stabilize maintenance budgets and preserve engine efficiency over thousands of operating hours.

What to look for when sourcing PLUG-IN FLANGE OEM parts

Specify the media (fuel, LO, CW, charge air, exhaust), pressure/temperature envelope, gasket type, face finish and bolt material class. Confirm alignment features (pilots/dowels), coating systems, NDT requirements (e.g., MPI/UT where applicable), and documentation packages. For marine engine projects, verify compatibility with class rules and that parts are traceable to recognized manufacturing lots.

MOPA: fast, reliable supply of PLUG-IN FLANGE holders, plates and flanges

MOPA is an experienced partner for OEM spare parts suitable for holders, plates and flanges across diesel and gas engines. Customers rely on our speed—short lead times, agile sourcing and efficient logistics—and on consistent quality verified through robust supplier qualification and documentation. Our trading processes emphasize security: clear traceability, authenticity checks, and careful handling to protect precision-machined surfaces. Whether you need a PLUG-IN FLANGE marine engine connection kit, mounting plates for a cooling module, or heavy-duty holders for ancillary equipment, MOPA delivers the right specifications on time.

Conclusion: PLUG-IN FLANGE holders, plates and flanges in focus

Holders, plates and flanges—especially precision PLUG-IN FLANGE interfaces—are foundational to engine reliability, sealing integrity and serviceability. Selecting OEM spare parts suitable for this category ensures accurate fit, stable performance and longer service life while controlling maintenance costs. With MOPA as your partner, you secure fast, high-quality supply for diesel and gas engine requirements.