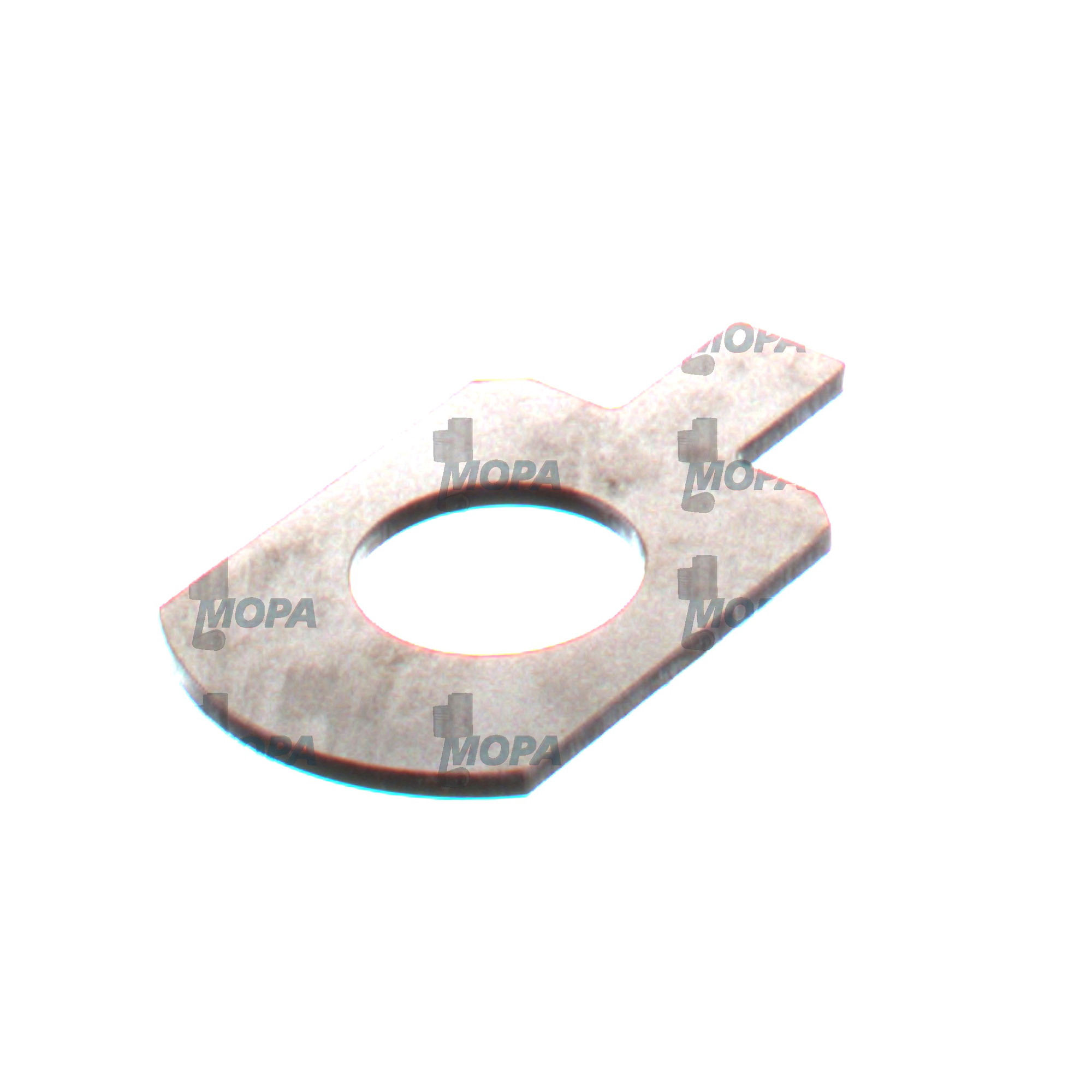

SPACER holders, plates and flanges for demanding engine applications

Holders, plates and flanges are precision-engineered hardware that create stable, accurately aligned interfaces across an engine. From mounting pumps and alternators to joining pipework and drivetrain housings, these components keep assemblies in position, distribute loads, and maintain sealing faces under heat, vibration, and pressure. Within this category, the SPACER plays a central role: it sets exact distances between parts, compensates tolerances, and preserves axial alignment. In marine and power-generation environments, where uptime and safety are paramount, robust holders, plates, flanges and well-specified spacers safeguard performance and extend engine life.

Technical function of holders, plates and flanges with SPACER in diesel engine and marine engine setups

On a diesel engine or marine engine, holders secure ancillary equipment—such as fuel pumps, filters, turbocharger actuators, and sensor brackets—so that load paths remain predictable and vibrations are controlled. Plates provide flat, rigid bases for equipment, ensuring bolt preload is maintained and gasket compression remains uniform. Flanges form strong, sealed connections between pipe sections, turbocharger inlets, exhaust manifolds, charge-air coolers, and cooling circuits.

The SPACER is the dimensional backbone within these assemblies. A correctly machined SPACER aligns shaft centers, sets bearing preload, preserves gear backlash, and prevents axial loads from migrating into components that are not designed to carry them. In rotating equipment, microns of axial misalignment can translate into heat, wear, and energy loss. By using a SPACER sized to the application—whether for a marine engine coupling, a diesel engine accessory drive, or compressor mounting—engineers keep tolerances within design intent, reduce runout, and stabilize vibration signatures.

Thermally, holders, plates, and flanges must accommodate differential expansion without compromising sealing faces. A SPACER made from compatible materials and finishes maintains dimensional stability as temperatures cycle, sustaining gasket compression and bolt tension. Corrosion-resistant alloys or coatings prevent crevice corrosion at joints, especially in saline atmospheres and wet exhaust sections. Surface flatness, concentricity, and perpendicularity of flanges and plates, together with the right SPACER thickness and hardness, ensure the integrity of high-pressure fuel, lube oil, and cooling circuits.

- · Precise axial and radial alignment under dynamic loads

- · Stable sealing faces for exhaust, charge air, fuel and coolant joints

- · Controlled bolt preload and uniform gasket compression

- · Vibration damping through rigid, well-matched interfaces

- · Corrosion-resistant materials and engineered surface finishes

- · Dimensional fidelity of the SPACER to maintain tolerances

- · Compatibility with diesel and gas engine operating temperatures

- · Service-friendly layouts enabling fast inspections and replacements

Why SPACER holders, plates and flanges are critical for engine reliability

Reliability depends on keeping components aligned and sealed across thousands of hours. If holders loosen, plates distort, or flanges warp, preload is lost and joints begin to leak or fret. Without the correct SPACER, axial offset increases bearing temperatures, couplings vibrate, and gears develop abnormal patterns that accelerate wear. In worst cases, leaks in exhaust or fuel lines create safety hazards; misalignment leads to shaft damage or unplanned shutdowns; and recurring vibration invites fatigue cracking at brackets and welded supports.

Conversely, when the SPACER dimension is correct and interfaces are machined to specification, the drivetrain runs smoother, seals last longer, and energy losses are minimized. Fuel efficiency benefits from reduced parasitic friction, noise levels drop, and maintenance intervals can be extended thanks to stable mounting conditions.

Advantages of OEM spare parts suitable for holders, plates and flanges

Using OEM spare parts suitable for holders, plates and flanges helps preserve the engineered stack-up of tolerances that the engine was designed around. SPACER OEM parts match the required metallurgy, hardness, and surface finish, enabling predictable bolt stretch, repeatable gasket seating, and consistent thermal behavior. For purchasers and fleet managers, this means fewer alignment corrections during overhaul and less risk of dimensional drift after hours of cyclic loading.

How OEM spare parts support performance, reliability, budget and service life

Performance is protected because the intended geometry is restored at every maintenance event. Reliability improves when SPACER thickness, concentricity, and flatness adhere to spec; bolts keep their preload and joints remain tight in operation. From a budget perspective, correct fits reduce rework time, prevent collateral damage to shafts and bearings, and minimize consumables through stable sealing pressure. Service life increases when holders resist fretting, plates stay flat under temperature gradients, and flanges maintain face integrity during repeated heat cycles—all achievable with correctly specified OEM parts.

MOPA as your partner for OEM parts: holders, plates and flanges with SPACER precision

MOPA supplies OEM spare parts suitable for holders, plates and flanges across leading diesel and gas engine platforms. Customers rely on our speed of delivery to shorten layovers, our consistent quality to maintain alignment and sealing integrity, and our secure procurement process to reduce supply-chain risk. Whether you need a SPACER for a marine engine coupling, a flange set for a charge-air system, or mounting plates for auxiliary systems, MOPA provides traceable, specification-true components that fit first time and perform in tough environments.

Conclusion: SPACER holders, plates and flanges that keep engines on spec

Holders, plates and flanges—backed by the correct SPACER—are fundamental to alignment, sealing, and vibration control in marine and diesel engines. Choosing OEM spare parts suitable for this category protects performance, reduces lifecycle costs, and extends operating hours with dependable dimensional accuracy and material quality.