TAB WASHER holders, plates and flanges for demanding engine applications

Holders, plates and flanges form a robust mounting and connection ecosystem inside every large engine. These components position and secure pumps, sensors, pipework, housings and rotating assemblies, while distributing loads and sealing interfaces exposed to heat, vibration and pressure. Within this category, the TAB WASHER is the critical locking element that prevents fasteners from loosening. For marine engine and diesel engine installations that run for thousands of hours under cyclic loads, the synergy of holders, plates, flanges and TAB WASHER solutions is indispensable for safe, efficient operation.

From bracket-style holders and structural backing plates to precision-machined flanges, each element supports alignment, torque transmission and sealing integrity. A properly specified TAB WASHER OEM parts set locks nuts and bolts at these interfaces, providing a simple, failsafe secondary retention that inspectors can verify at a glance.

Technical function of holders, plates and flanges with TAB WASHER in diesel engine and marine engine service

Holders maintain the exact location of auxiliaries—fuel pumps, charge-air coolers, filters and instrumentation—so clearances remain within specification during operation. Plates spread clamping forces over a larger area, preventing local yielding at cast housings and thin-wall structures, and they add stiffness to reduce vibratory response. Flanges couple shafts, connect exhaust and cooling circuits, and provide repeatable, gasket-friendly sealing faces capable of sustaining thermal cycling.

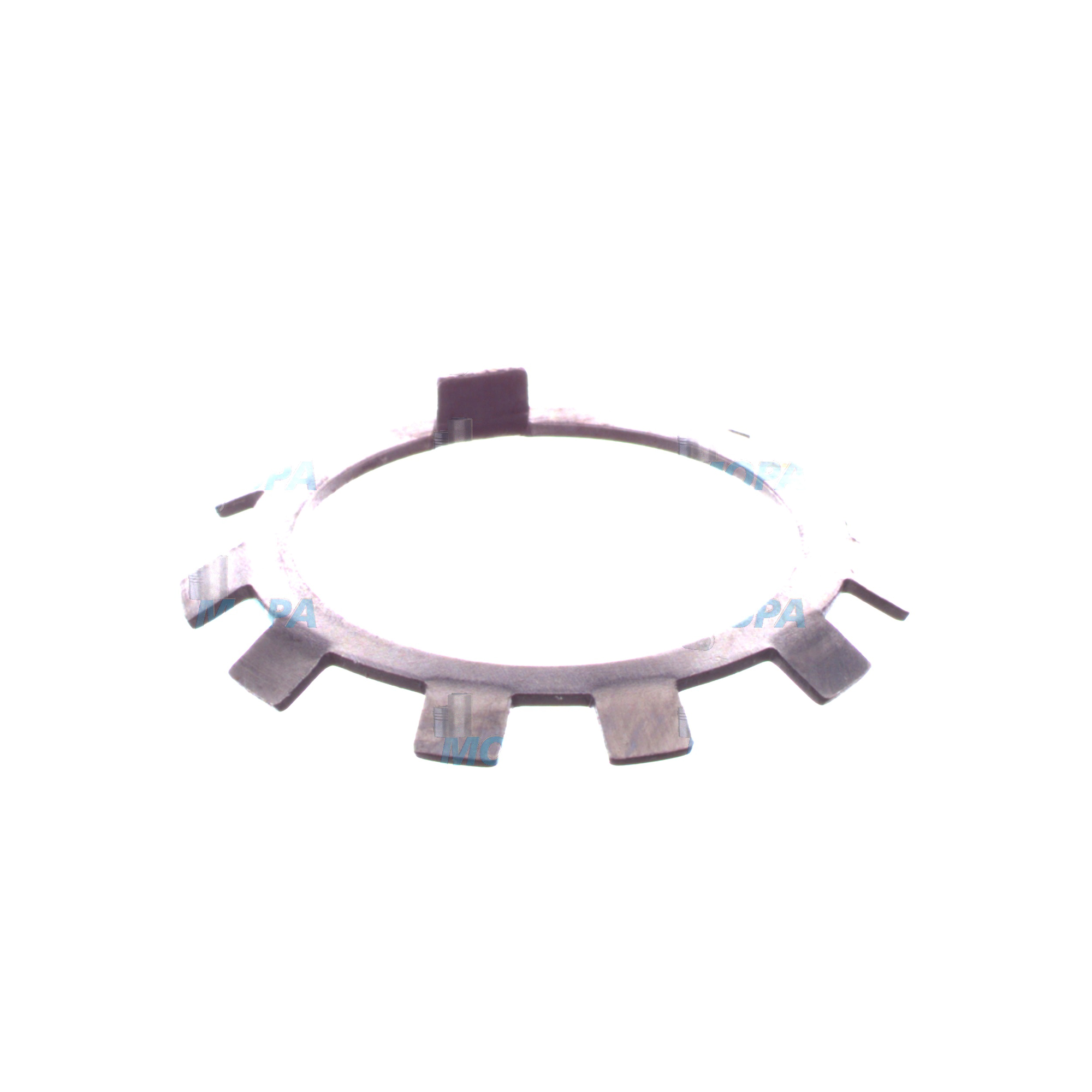

The TAB WASHER complements these parts by mechanically locking a fastener after torqueing. Typically stamped from spring or stainless steel, it features one or more tabs that are bent into a keyway, against a nut flat or onto an adjacent housing. Once formed, the tab resists back-off even if vibration, creep or thermal relaxation reduces preload. Common locations include turbocharger brackets, exhaust manifold flanges, coupling flanges on propulsion shafts, pump drive flanges and main-bearing cap retainers in heavy-duty diesel engines.

Effective design depends on correct hardness and thickness to balance formability with resistance to tab fatigue, corrosion protection (e.g., zinc flake or stainless grades for seawater proximity), and precise inner/outer diameters that match nut sizes or key slots. When paired with flat plates and machined flanges of the right surface finish and flatness, TAB WASHER locking helps maintain gasket seating stress and joint integrity across long service intervals.

- · Positive-locking retention under high vibration.

- · Visual verification of fastener security during inspections.

- · Load distribution via plates to reduce fretting and distortion.

- · Precision flanges for torque transfer and leak-tight sealing.

- · Material options for heat and corrosion resistance.

- · Compatible with standard nut sizes and keying features.

Importance of holders, plates and flanges with TAB WASHER for reliable engine operation

Reliability in propulsion and power-generation engines hinges on joint stability and alignment. If holders loosen, components drift out of position, leading to belt mis-tracking, sensor errors or chafed hoses. If plates are undersized or fatigued, clamping loads concentrate, leading to bolt-hole elongation, fretting, and eventual bolt relaxation. If flanges lose preload or warp, the result can be exhaust leaks, loss of charge-air pressure, coolant loss or misalignment of rotating couplings—each a threat to efficiency and safety.

Without a properly fitted TAB WASHER, a nut can gradually rotate under cyclical torsion or vibration, especially at elevated temperatures where joint creep occurs. Progressive loss of preload increases joint slip, accelerates wear and can end in sudden failure. Warning signs include discolored or cracked plates, visible tab fractures, ovalized holes, corrosion at flange faces, soot deposits at exhaust joints and witness marks around fasteners indicating micro-movement. Scheduled inspections should confirm that each TAB WASHER tab is correctly bent and seated and that plates and flanges meet flatness and surface criteria after disassembly.

Advantages of OEM spare parts suitable for holders, plates and flanges with TAB WASHER OEM parts

Choosing OEM spare parts suitable for holders, plates and flanges ensures the dimensions, materials and heat treatments align with engine-maker specifications. This precision preserves torque retention and sealing margins designed into the engine. TAB WASHER OEM parts for diesel engines, for example, match nut across-flats tolerances and tab height, preventing partial engagement that could shear under load. Likewise, flange face finishes, plate thicknesses and holder geometries are matched to gasket types, bolt classes and installation clearances.

For fleet operators and shipowners, the practical benefits are clear: consistent clamp loads after torqueing, lower risk of rework during overhauls, and predictable inspection outcomes across vessels or plants. Over the equipment lifecycle, this translates into fewer unplanned stoppages, reduced consumable costs from leaks or misalignments, and stable performance metrics such as fuel efficiency and emissions compliance.

How OEM spare parts support performance, budget and service life

Because OEM spare parts suitable for this category are engineered for specific joint designs, they minimize the hidden costs of mismatched hardware: premature gasket failures, uneven contact pressure, and fastener relaxation. Material traceability and controlled coatings protect against corrosion in saline atmospheres, while repeatable fit-up shortens dockside or plant maintenance windows. In short, TAB WASHER OEM parts and correctly specified holders, plates and flanges keep engines operating at their intended efficiency while protecting capital equipment.

MOPA: your partner for TAB WASHER, holders, plates and flanges OEM parts

MOPA supplies OEM parts for diesel and gas engines with a focus on speed, quality and security in every transaction. Our team supports purchasers and superintendents with rapid identification of holders, plates and flanges, cross-referencing part numbers and providing TAB WASHER options for marine engine applications. Stock availability, reliable lead times and careful packaging help ensure components arrive ready for installation, while documentation and batch traceability support compliance and audit requirements.

Whether you need flange kits for exhaust sections, precision plates for structural reinforcement or TAB WASHER sets for shaft-coupling fasteners, MOPA streamlines procurement and reduces operational risk across mixed engine portfolios.

Conclusion: TAB WASHER and the role of holders, plates and flanges

Holders, plates and flanges provide the structural backbone and sealing integrity of engines, while the TAB WASHER delivers simple, dependable fastener security in high-vibration environments. Selecting OEM spare parts suitable for this category safeguards performance, extends service life and protects budgets by reducing downtime and rework.