CORRUGATED TUBE lines and pipes for high‑performance engine systems

Lines and pipes are the circulatory network of any engine. They route fuel, lube oil, coolant, compressed air, exhaust, and process gases safely and efficiently between critical components. Within this category, the CORRUGATED TUBE adds controlled flexibility and vibration absorption where rigid routing is impossible or thermal expansion must be managed. For marine engine rooms, power plants, and industrial installations, correctly engineered lines and pipes determine how reliably an engine starts, how efficiently it runs, and how safely it is maintained.

Technical function of lines and pipes and CORRUGATED TUBE in marine engine and diesel engine systems

In an engine, media must flow at the right pressure, temperature, and cleanliness level. Seamless steel pipes, precision tubes, formed rigid lines, and flexible elements like CORRUGATED TUBE assemblies work together to deliver those conditions. Rigid pipes provide dimensional stability and low pressure loss for main circuits (fuel feed/return, jacket water, charge air coolers, lube oil galleries), while CORRUGATED TUBE elements compensate for engine movement, isolate vibration, and bridge misalignment between fixed equipment and machinery on resilient mounts.

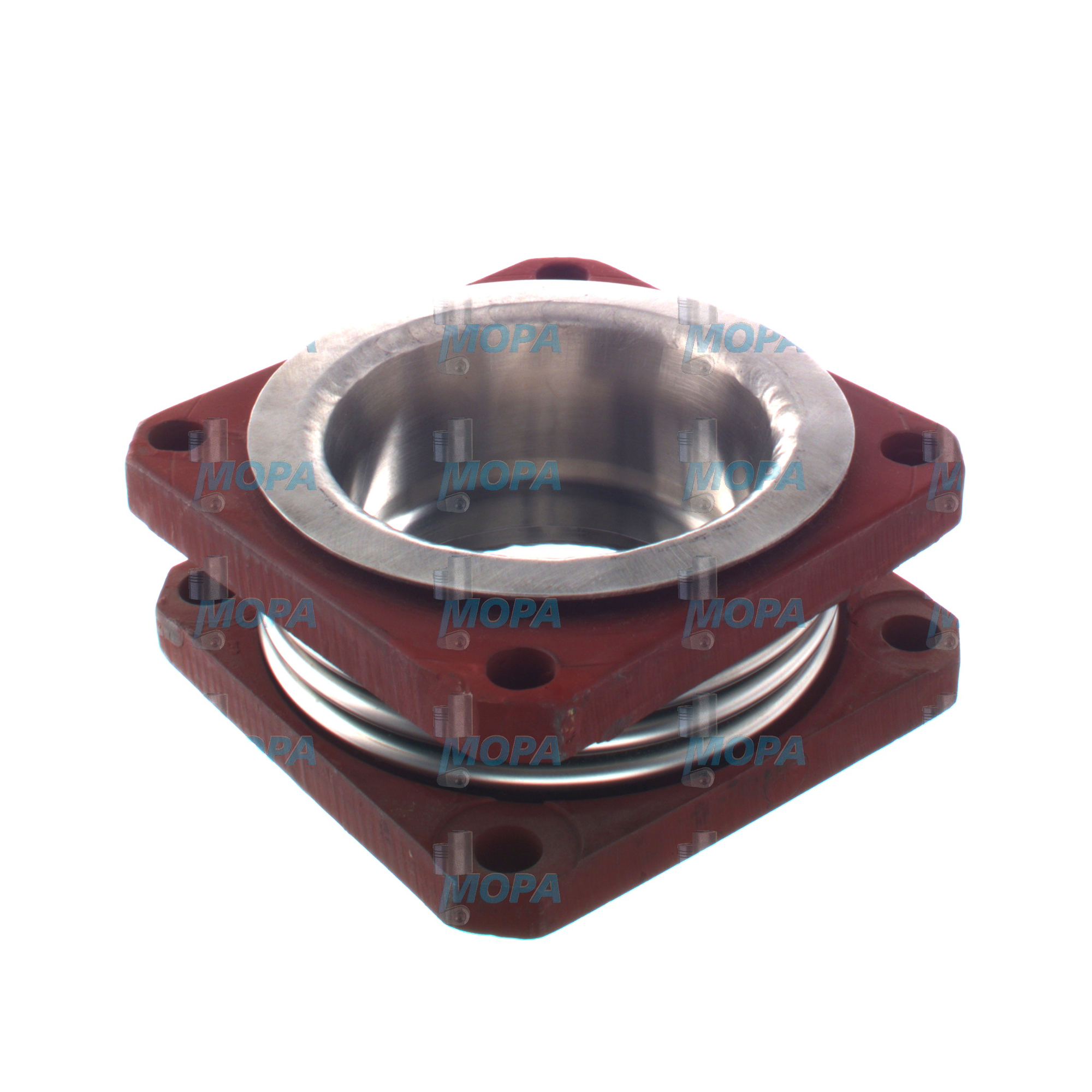

A CORRUGATED TUBE for marine engine duty typically uses thin‑wall stainless steel (e.g., 316L) with annular corrugations, optionally with an external braid for higher pressure ratings and to limit elongation. In diesel engine service, these tubes accommodate thermal growth and pulsation near pumps, filters, and heat exchangers, reducing fatigue stress on adjoining hard lines. Smooth‑bore PTFE‑lined corrugated hoses are often used for chemically aggressive media, while metal bellows and expansion joints protect exhaust branches against thermal cycles and hull deflection. Correct end connection selection—weld ends, flanges, flared or double‑ferrule fittings—ensures leak‑tight integration into the engine’s piping architecture.

From a design perspective, sizing is driven by flow rate, viscosity, permissible velocity, and acceptable pressure drop. Minimum bend radius, vibration spectrum, and support spacing define routing choices for flexible runs. Cleanliness is crucial: pre‑cleaned pipes, capped ends, and filtered flushing prevent injector scoring, valve sticking, and bearing damage. Where fire integrity is required, double‑walled fuel lines or fire‑sleeved assemblies provide additional protection in hot zones.

- · Leak‑tight transfer of fuel, oil, coolant, air, and exhaust.

- · Vibration isolation and movement compensation via corrugations.

- · Corrosion resistance with 316L, duplex, or nickel alloys.

- · Stable pressure and flow with engineered diameters and wall thicknesses.

- · Thermal expansion management in hot sections and exhaust trunks.

- · Fast service with standardized flanges and fitting interfaces.

- · Cleanliness control for injector and bearing protection.

When specified as CORRUGATED TUBE OEM parts, assemblies are supplied to exact length, end‑connection geometry, braid coverage, and pressure/temperature ratings, ensuring drop‑in compatibility with the engine builder’s piping models and installation envelopes.

Why lines and pipes with CORRUGATED TUBE matter for reliable engine operation

Reliability and service life hinge on the integrity of lines and pipes. Any leak, restriction, or vibration‑induced crack can escalate into costly downtime or safety incidents. Fuel system line degradation introduces air into the injection circuit, causing misfires, power loss, and excessive smoke. Lube oil line defects reduce supply pressure, accelerating wear on bearings and turbochargers. Coolant pipe corrosion and scaling cause localized overheating, liner cavitation, and thermal stress. In exhaust systems, a collapsed or improperly rated CORRUGATED TUBE elevates back pressure, damaging turbochargers and increasing exhaust temperatures.

Marine environments add chloride‑driven corrosion and constant vibration, so materials, wall thickness, and supports must be matched to the duty profile. Regular inspection should focus on abrasion points, unsupported spans, braid condition, fitting torque marks, and any cold work near bends. Correctly selected and maintained lines and pipes stabilize pressure pulsations, protect sensitive components, and preserve the engine’s designed performance and emissions profile over long service intervals.

Advantages of OEM spare parts suitable for lines and pipes and CORRUGATED TUBE OEM parts

OEM spare parts suitable for lines and pipes ensure that materials, geometry, and connection standards match the engine’s baseline design. Dimensional accuracy preserves flow coefficients and keeps pressure drops within specification. Verified metallurgy and heat treatment deliver predictable fatigue life under pulsating loads. Surface finish and cleanliness minimize contamination risks in high‑precision fuel and hydraulic circuits. With CORRUGATED TUBE OEM parts, braid coverage, corrugation pitch, and end fittings are tuned to the required movement envelope and vibration spectrum, preventing premature work hardening or kink failures.

For purchasers and technical decision‑makers, the benefits are measurable: consistent performance across units, reduced installation time due to perfect fit, lower lifecycle costs via extended service intervals, and assured compatibility with clamps, supports, and sealing faces already on board. Documentation such as pressure test records and material certificates supports compliance with class and safety management systems, while stable sourcing simplifies inventory planning across diesel and gas engine fleets.

MOPA: fast, secure supply of OEM parts for lines and pipes and CORRUGATED TUBE

MOPA is an experienced partner for sourcing OEM spare parts suitable for lines and pipes, including CORRUGATED TUBE assemblies for marine engine and diesel engine applications. We focus on speed, quality, and security in the trade of OEM parts for diesel and gas engines: rapid quotations, short lead times from stocked references, and tightly controlled logistics that protect sensitive, pre‑cleaned components. Our team cross‑references part numbers, drawings, and installation constraints to ensure the correct specification every time, backed by traceable documentation and pressure testing data where applicable.

Support for diesel and gas engines across fleets

Whether you need a single fuel return line, a complete lube oil manifold, or a braided CORRUGATED TUBE to isolate a charge air cooler, MOPA delivers technically correct parts with reliable timelines. We help shipowners and operators standardize their spares portfolio, align with maintenance windows, and keep critical engines online with minimal disruption.

Conclusion: CORRUGATED TUBE and lines and pipes keep engines safe and efficient

Lines and pipes, including the flexible CORRUGATED TUBE, are fundamental to engine performance, efficiency, and safety. Selecting and maintaining the right components protects uptime and extends asset life. OEM spare parts suitable for lines and pipes provide the precision, reliability, and value that technical operators require to keep diesel and gas engines running at their best.