FLOW RESTRICTOR lines and pipes for marine and diesel engines

Lines and pipes are the engineered arteries of any engine, routing fuel, lube oil, cooling water, charge air, and hydraulics with controlled pressure and flow. In large marine engine rooms and compact diesel engine installations alike, this network of rigid tubing, flexible hoses, and manifolds is designed to maintain precise flow rates, resist vibration, and withstand thermal and chemical loads. Within this system, the FLOW RESTRICTOR is frequently integrated as a calibrated element to limit, meter, or stabilize flow, protecting critical components and improving overall operating stability.

From main engine fuel rails to jacket water circuits and starting-air manifolds, the integrity of lines and pipes defines performance and reliability. Materials, geometry, and joining methods (flared, double-ferrule, welded, or brazed) are selected for pressure class and media compatibility, while supports and clamps prevent fretting and fatigue. Thoughtful integration of a FLOW RESTRICTOR in a marine engine or diesel engine helps maintain design setpoints even under dynamic load changes.

Technical function of lines and pipes with a FLOW RESTRICTOR

Every engine depends on predictable fluid dynamics. Lines and pipes govern flow by combining internal diameter, surface finish, route length, bending radii, and end connections. A FLOW RESTRICTOR—implemented as a calibrated orifice, jet, or needle—adds a fixed hydraulic resistance to a branch or subsystem. In a diesel engine lubrication circuit, for example, it can prioritize oil supply to bearings by limiting bypass flow. In charge-air or cooling circuits, it dampens transients, reducing pressure spikes and oscillations that can cause cavitation or component stress.

On marine engine installations, FLOW RESTRICTOR components ensure stable fuel return rates, controlled cylinder cooling, and balanced lube oil distribution across long pipe runs. Correctly specified restrictors reduce the risk of overfeeding sensitive equipment such as turbocharger bearings, hydraulic lash adjusters, or pilot control valves. When aligned with OEM parts standards, the restrictor’s bore accuracy and edge quality maintain predictable Reynolds regimes and avoid unwanted turbulence, noise, or aeration.

- · Corrosion-resistant alloys (e.g., 316L, CuNi 90/10, CuNi 70/30) for seawater and fuel environments.

- · Pressure-rated designs for high loads, including common-rail fuel lines up to very high bar levels.

- · Fire-protected hoses and double-walled fuel lines to enhance engine-room safety.

- · Precision bends and consistent wall thickness for stable flow and low pressure drop.

- · Robust supports, clamps, and compensators to mitigate vibration and thermal expansion.

- · Cleanliness-controlled assembly to ISO and class requirements for contamination-sensitive systems.

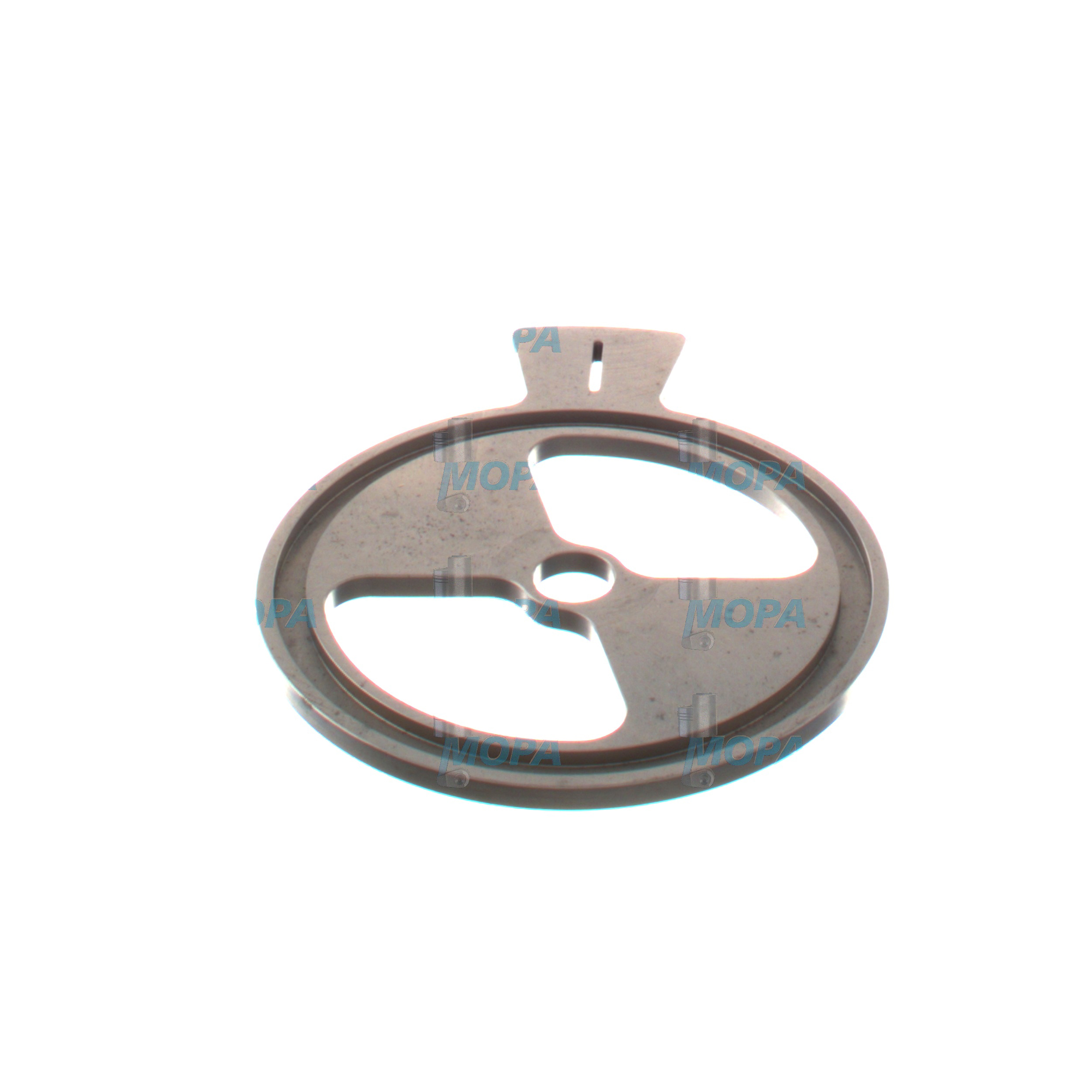

- · FLOW RESTRICTOR options: orifice plates, calibrated jets, and needle-style restrictors.

Why lines and pipes are crucial for reliable engine operation

Reliability and service life hinge on the condition of the piping network. Wear, corrosion, or improper routing can lead to leakage, entrained air, and pressure loss. In fuel systems, micro-leaks or internal restrictions cause poor atomization, injector coking, and increased specific fuel oil consumption. In lubrication circuits, flow instability risks bearing starvation, elevated metal temperatures, and accelerated wear. Cooling-water issues—often stemming from fouled or undersized lines—trigger hotspots, liner cavitation, and cracking. Even starting-air and control lines, if compromised, can lead to slow starts, misfires, or safety system malfunctions.

A mis-specified or clogged FLOW RESTRICTOR magnifies these risks. Oversized restrictors may allow excessive flow, causing vibration, noise, or thermal shock. Undersized or contaminated restrictors starve components, reduce turbocharger life, and create unbalanced temperatures across cylinder banks. Routine inspection of lines and pipes, confirmation of bore integrity, and timely replacement of FLOW RESTRICTOR elements are therefore essential tasks for fleet engineers and power plant operators.

Advantages of OEM spare parts suitable for lines and pipes with FLOW RESTRICTOR

OEM spare parts suitable for lines and pipes preserve the engineered geometry, metallurgy, and cleanliness that the engine designer intended. Tolerances on tube ID, concentricity, and restrictor bore diameter directly affect pressure drop and distribution; using OEM ensures the correct flow coefficients without trial-and-error on site. Surface treatments, passivation, and lining options (such as PTFE) are matched to the media, temperature, and pressure, protecting against corrosion and permeation. Traceability and documentation support compliance with class, flag, and safety audits.

From a budget and uptime perspective, OEM spare parts reduce rework, minimize commissioning delays, and support predictable maintenance planning. Drop-in fit saves labor hours, while consistent performance avoids secondary damage that often costs orders of magnitude more than the component itself. For FLOW RESTRICTOR OEM parts, the calibrated orifice quality—edge sharpness, bore alignment, and burr-free finish—delivers repeatable flow under real-world viscosities and operating temperatures.

How the right specification protects performance

Correct alloy and wall thickness prevent stress corrosion cracking and erosion in high-velocity sections. Certified hose assemblies with crimped fittings keep permeability low in fuel service. Proper clamp spacing and flexible sections absorb engine movement, preventing fretting on manifolds and accessories. Together with a correctly sized FLOW RESTRICTOR diesel engine setup, these details safeguard efficiency, emissions compliance, and component longevity.

MOPA: your partner for OEM lines, pipes, and FLOW RESTRICTOR solutions

MOPA supplies OEM spare parts suitable for lines and pipes across diesel and gas engines with a focus on speed, quality, and security in trade. Our team cross-references part numbers, verifies materials and pressure classes, and provides documentation to align with shipyard and operator requirements. Whether you need a FLOW RESTRICTOR for a marine engine fuel return line or a complete lube oil piping kit, we help you source the right parts quickly and reliably.

Global logistics support, careful packaging, and clear documentation shorten layovers and dry-dock times. With MOPA, purchasers, shipowners, and technical decision-makers gain a trusted channel for consistent OEM parts that maintain design performance and support safe operation.

Conclusion: lines and pipes with FLOW RESTRICTOR

Lines and pipes form the circulatory system of any power unit, and incorporating the correct FLOW RESTRICTOR ensures stable, predictable operation in both marine engine and diesel engine applications. Choosing OEM spare parts suitable for lines and pipes protects performance, reliability, operating budgets, and the service life of critical components. MOPA delivers the parts and expertise to keep these systems functioning exactly as engineered.