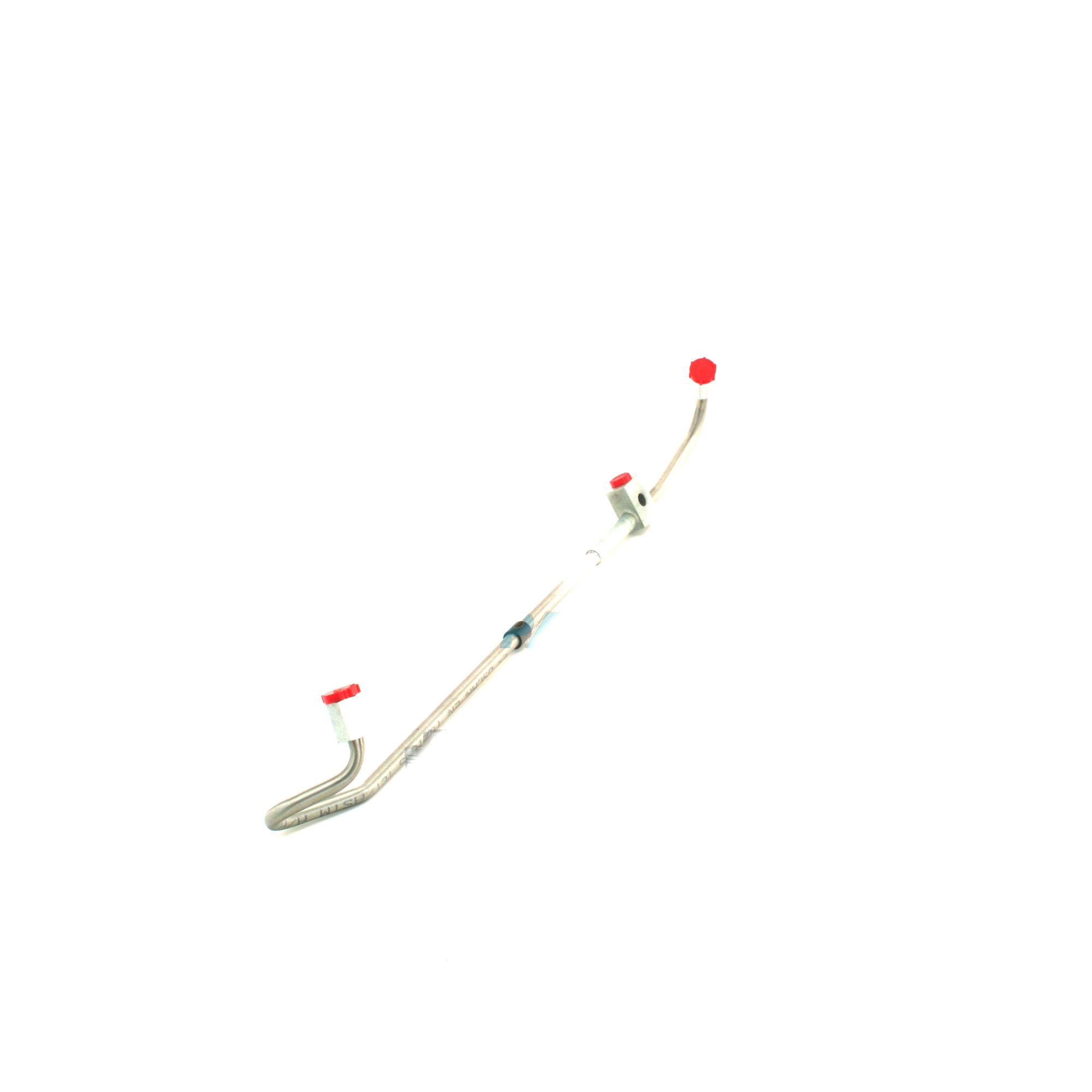

INJECTION LINE (leakage secured) – Lines and pipes for high‑pressure, safety‑critical fuel systems

Lines and pipes are the circulatory system of any engine. They route and protect fuel, lubricating oil, coolant, charge air, and exhaust treatment media under demanding thermal and mechanical loads. Within this category, the INJECTION LINE (leakage secured) stands out as a safety‑critical component in marine engine and diesel engine applications. It not only delivers precisely metered fuel at extreme pressures but also controls and contains leaks, protecting crews, equipment, and uptime.

Engineered lines and pipes ensure dependable media flow, withstand vibration and pressure pulsation, and maintain tightness at connections and bends. For high‑pressure fuel circuits, leakage‑secured injection pipes add an outer containment layer and leak‑off routing, making them indispensable where regulatory and operational safety requirements are stringent—especially at sea and in power generation.

Technical function of lines and pipes and the INJECTION LINE (leakage secured) in a diesel engine

In a diesel engine, the fuel injection system must deliver fuel to each injector with exact timing, volume, and spray quality. The INJECTION LINE (leakage secured) is the conduit between the high‑pressure pump or common‑rail manifold and the injector. It must contain cyclical pressures that routinely reach hundreds of bar—and in many cases exceed a thousand bar—while maintaining dimensional stability and surface integrity to preserve injection timing and atomization.

Pressure dynamics, routing, and atomization

Precision internal diameter, wall thickness, and line length are critical. Even minor deviations can alter wave propagation and pressure peaks, shifting the start of injection or deteriorating spray formation. Correct routing with defined bend radii and clamp spacing minimizes vibration, reduces stress concentration, and prevents fretting. This preserves injector life, stabilizes combustion, and supports fuel efficiency.

Leakage‑secured (double‑walled) design for marine engine safety

A leakage‑secured injection pipe integrates an inner high‑pressure line with an outer protective sleeve. Any seepage from the inner pipe is captured and guided through a leak‑off connection to a safe collection point or tank. Many marine engine installations require this arrangement to minimize fire risk by preventing free fuel spray in the engine room and to enable leak detection through sensors or sight lines. The design adds a safety envelope without compromising pressure dynamics inside the core line.

Materials, connections, and compliance

Lines and pipes for high‑pressure fuel service are typically manufactured from high‑strength, corrosion‑resistant steel with controlled surface hardness and cleanliness to resist pulse‑fatigue. End connections—cones, nuts, collars, and ferrules—must match the mating pump/injector geometry. Tightness relies on precision seating and correct torque, backed by pressure and leak testing. For the INJECTION LINE (leakage secured) OEM parts, traceable materials, consistent heat treatment, and verified burst/pulse test data help ensure reliable operation in harsh, high‑temperature spaces.

· High‑pressure capable inner line with controlled ID and wall thickness.

· Outer containment sleeve and routed leak‑off for safe spill management.

· Optimized length, bends, and clamp points to stabilize pressure waves.

· Corrosion‑resistant materials and heat treatment for pulse‑fatigue life.

· Precision end fittings for pump and injector interfaces.

· Factory pressure and leak testing, with documentation and traceability.

Importance of lines and pipes for engine reliability and service life

Reliability starts with stable flows and tight connections. Worn or damaged lines and pipes jeopardize combustion quality, elevate emissions, and stress critical components. On the fuel side, micro‑cracks, pitting, or poor seating cause pressure loss, delayed injection, and uneven cylinder loads. The result can be misfire, higher specific fuel oil consumption, injector coking, and premature pump wear. In severe cases, atomized diesel escape poses a fire hazard—precisely what the INJECTION LINE (leakage secured) is designed to control.

Beyond fuel, coolant and lubricating oil lines influence thermal balance and bearing protection. Leaks, blockages, or vibration damage can escalate into overheating, scuffing, or catastrophic failures. Properly engineered and maintained lines and pipes extend overhaul intervals, protect turbochargers and aftertreatment, and cut unplanned downtime—key priorities for shipowners and power plant operators.

Advantages of OEM spare parts suitable for lines and pipes

Specifying OEM spare parts suitable for the INJECTION LINE (leakage secured) and related lines and pipes ensures compatibility with engine tolerances and safety concepts. Dimensional fidelity, metallurgy, and surface finish are controlled to the engine maker’s standards, preserving pressure dynamics and leak tightness over long pulse‑fatigue cycles. This translates into steady performance, consistent emissions, and predictable maintenance planning.

From a budget standpoint, correct fit the first time reduces installation hours, avoids rework, and prevents collateral damage to costly components. For fleets, using OEM spare parts suitable for lines and pipes simplifies inventory, documentation, and compliance inspections. It also supports uniform behavior across sister vessels or units, making troubleshooting faster and reducing diagnostic uncertainty.

· Drop‑in fit for pump, rail, and injector interfaces reduces downtime.

· Verified pulse‑fatigue and burst performance supports long service life.

· Correct routing geometry preserves injection timing and fuel efficiency.

· Consistent materials and heat treatment enhance corrosion resistance.

· Traceability and documentation streamline audits and class inspections.

· Fleet‑wide standardization improves maintenance predictability.

INJECTION LINE (leakage secured) OEM parts: MOPA as your partner

MOPA is an experienced, reliable partner for OEM spare parts for lines and pipes, including every variant of the INJECTION LINE (leakage secured) for marine engine and diesel engine platforms. We focus on speed, quality, and security in the global trade of OEM parts for diesel and gas engines—supporting scheduled dockings as well as urgent AOG‑style requests. Our team helps you identify the correct references, match connection geometries, and select the right clamp sets and leak‑off accessories to complete the installation safely.

With MOPA, purchasers and technical managers gain a responsive supply chain, clear documentation, and confidence that critical fuel and utility lines meet the technical baseline your engines were designed around.

Conclusion: lines and pipes with leakage‑secured injection focus

Lines and pipes are foundational to engine performance and safety, and the INJECTION LINE (leakage secured) is central to clean combustion and fire‑safe operation. Choosing OEM spare parts suitable for lines and pipes protects efficiency, uptime, and asset life while meeting stringent safety expectations.

Partnering with MOPA gives you fast access to the right components, backed by technical know‑how and secure sourcing for diesel and gas engine fleets worldwide.