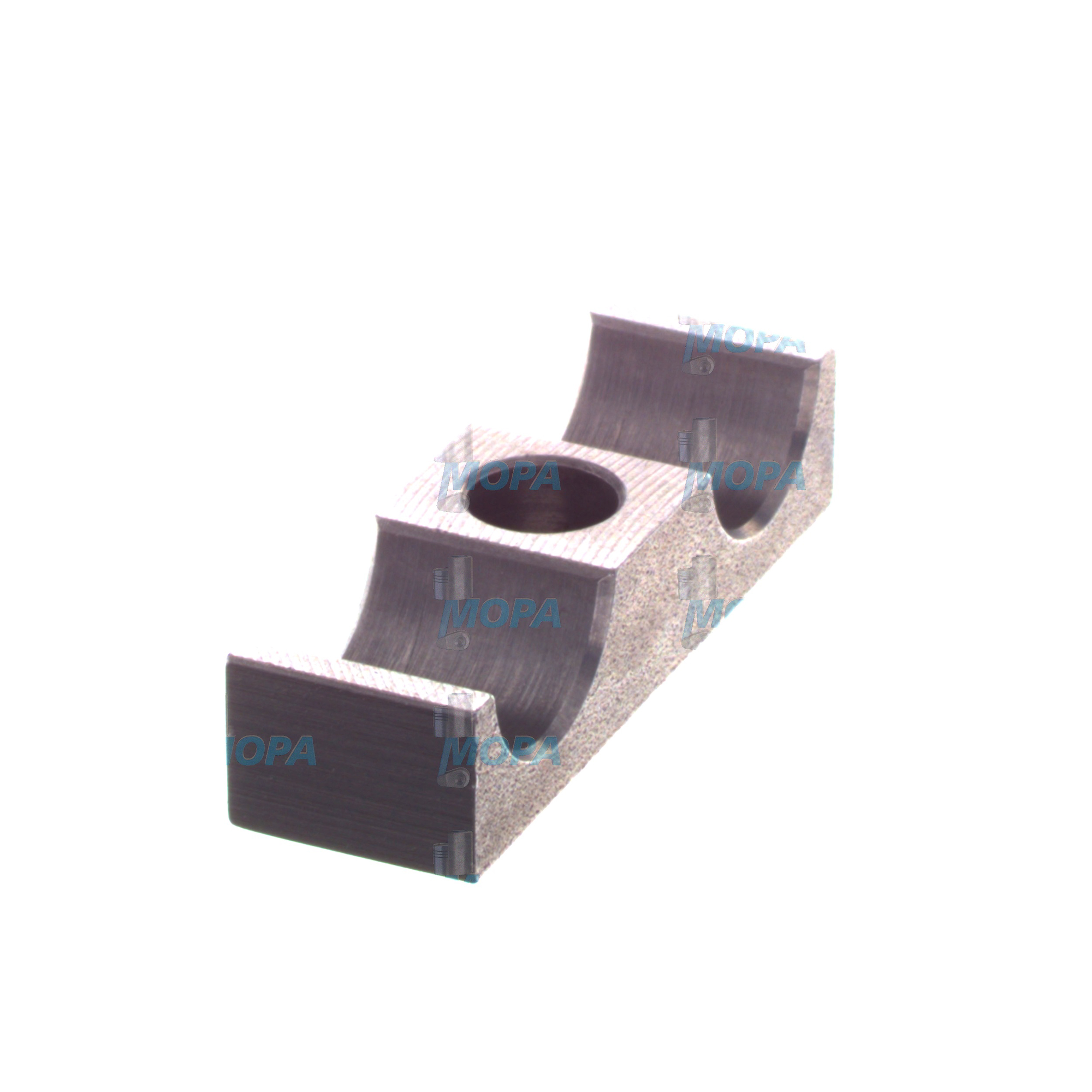

PIPE HALF-CLAMP for Lines and Pipes in Marine and Diesel Engines

Lines and pipes are the circulatory system of any gas or diesel engine. From high‑pressure fuel injection and lubrication to cooling, charge air, and hydraulic control, these routed networks ensure that media flows safely and precisely to every critical component. They comprise rigid pipes, flexible hoses, bends, manifolds, and connectors—securely supported by brackets and clamping elements such as the PIPE HALF-CLAMP—to withstand vibration, pressure pulsations, and thermal movement. In marine engine rooms and power plants alike, robust lines and pipes are fundamental to uptime, efficiency, and safety.

In practice, these assemblies must deliver exact volumes at stable pressures while resisting corrosion, abrasion, and heat. The geometry of each tube, the integrity of fittings, and the quality of supports define how reliably an engine operates over its service life. That is why the correct selection of materials, compliance with class rules, and the use of appropriate supports—including a well‑matched PIPE HALF-CLAMP—are decisive for long‑term performance.

PIPE HALF-CLAMP and the technical function of lines and pipes

Within a diesel engine or marine engine installation, lines and pipes route fluids under tightly controlled conditions. High‑pressure fuel lines deliver injection pulses without pressure drop or leakage; lube oil pipes maintain film stability at bearings; coolant pipes manage heat rejection; and compressed air or hydraulic lines actuate controls and starting systems. The PIPE HALF-CLAMP secures these runs to foundations and stringers, maintaining spacing, damping vibration, and preventing fretting. By fixing the pipe at calculated intervals, a PIPE HALF-CLAMP in a marine engine reduces dynamic deflection, keeps resonance away from operating speeds, and protects welds and fittings from fatigue.

Technically, engineered pipe routing minimizes turbulence and erosion with proper bend radii and smooth internal surfaces. Material selection follows duty: 316L or 254 SMO for seawater exposure, CuNi 90/10 for seawater cooling, precision carbon steel for fuel injection, and PTFE or FKM-lined hose assemblies where chemical compatibility is critical. Cleanliness and pressure integrity are verified through flushing (often to ISO 4406 codes), hydrostatic tests, and documented leak checks. The PIPE HALF-CLAMP OEM parts complement this by ensuring contact surfaces distribute clamping loads, avoiding point stress and coating damage on the pipe.

- · Robust media control under pressure and temperature.

- · Corrosion-resistant materials matched to the medium.

- · Precision bends minimize pressure loss and noise.

- · Secure restraint with PIPE HALF-CLAMP spacing to prevent fatigue.

- · Leak-tight connections with proven standards and fittings.

- · Compliance with marine class and safety regulations.

- · Cleanliness management for injector and valve protection.

- · Tested burst and proof pressures for operational safety.

Why lines and pipes—and the PIPE HALF-CLAMP—matter for engine reliability

Reliability depends on stable flow and physical integrity. If lines and pipes corrode, chafe, or lose support, the consequences can be severe: fuel mist and hot surfaces create fire risk; lube oil loss accelerates bearing wear; coolant leaks trigger overheating and liner distortion; air leaks reduce turbocharger efficiency; and hydraulic pressure loss disables controls. In a diesel engine, unsupported pipe spans can resonate with injection pulsation, causing cracks at flare seats or brazed joints. A correctly sized PIPE HALF-CLAMP positions the pipe, limits movement, and prevents fretting under dynamic loads, thereby extending the life of both piping and neighboring equipment.

Common issues that arise when components are not in proper condition include micro‑leaks at fittings from misalignment, pitting from stagnant seawater, blistering of poor coatings, and fatigue near rigid anchors. Regular inspection of supports and timely replacement of worn clamps and lines are essential to maintain compliance and operational safety.

OEM spare parts for lines and pipes: performance advantages with PIPE HALF-CLAMP

Choosing OEM spare parts suitable for lines and pipes is a practical decision that directly affects performance, reliability, budget, and service life. Dimensional fidelity ensures that bends, lengths, and end connections fit without stress, preventing forced alignment that leads to premature failure. Surface finishes and heat treatments meet the design’s burst and proof pressures, preserving injection accuracy and flow coefficients. With OEM parts, a PIPE HALF-CLAMP interfaces correctly with pipe OD, coating thickness, and saddle geometry, distributing loads as engineered.

Beyond mechanical fit, traceable materials and validated test records support compliance with class and safety requirements. Installation time is reduced because parts mate correctly with existing brackets, manifolds, and frames, saving labor and minimizing downtime. Over the asset life, fewer leaks, fewer retightening cycles, and less vibration-induced damage translate into lower total cost of ownership—particularly important for shipowners and plant operators running tight maintenance windows.

MOPA: fast, secure supply of OEM parts for lines and pipes and PIPE HALF-CLAMP

MOPA is an experienced, reliable partner for sourcing OEM spare parts for Lines and Pipes, including the PIPE HALF-CLAMP used in diesel and gas engines. Customers benefit from quick identification by part and serial numbers, short lead times, and consistent quality across fuel, lube oil, coolant, charge‑air, and hydraulic piping systems. MOPA’s processes emphasize speed, quality, and security—from quotation to documentation and delivery—ensuring that marine engine operators and power plant teams receive the right components on time and ready to install.

Whether you require complete pipe assemblies, precision bends, flexible hose sections, or the correct PIPE HALF-CLAMP OEM parts, MOPA supports projects ranging from routine overhauls to emergency repairs, with dependable logistics and technical clarity.

PIPE HALF-CLAMP OEM parts for marine engine and diesel engine applications

For retrofit or newbuild, the correct PIPE HALF-CLAMP for a marine engine or diesel engine protects adjacent components, preserves coating integrity, and maintains engineered pipe routing. Correct durometer inserts, saddle profiles, and corrosion‑resistant hardware are crucial to keep vibration in check and extend service intervals.

Conclusion: PIPE HALF-CLAMP and lines and pipes keep engines efficient and safe

Lines and pipes are central to engine performance and safety, and the proper use of supports like the PIPE HALF-CLAMP ensures stable, leak‑free operation under real‑world loads. Selecting OEM spare parts suitable for Lines and Pipes delivers the dimensional accuracy, material quality, and documentation needed to protect uptime and budgets. Partner with MOPA to secure fast, reliable access to the OEM components that keep your engines running at their best.