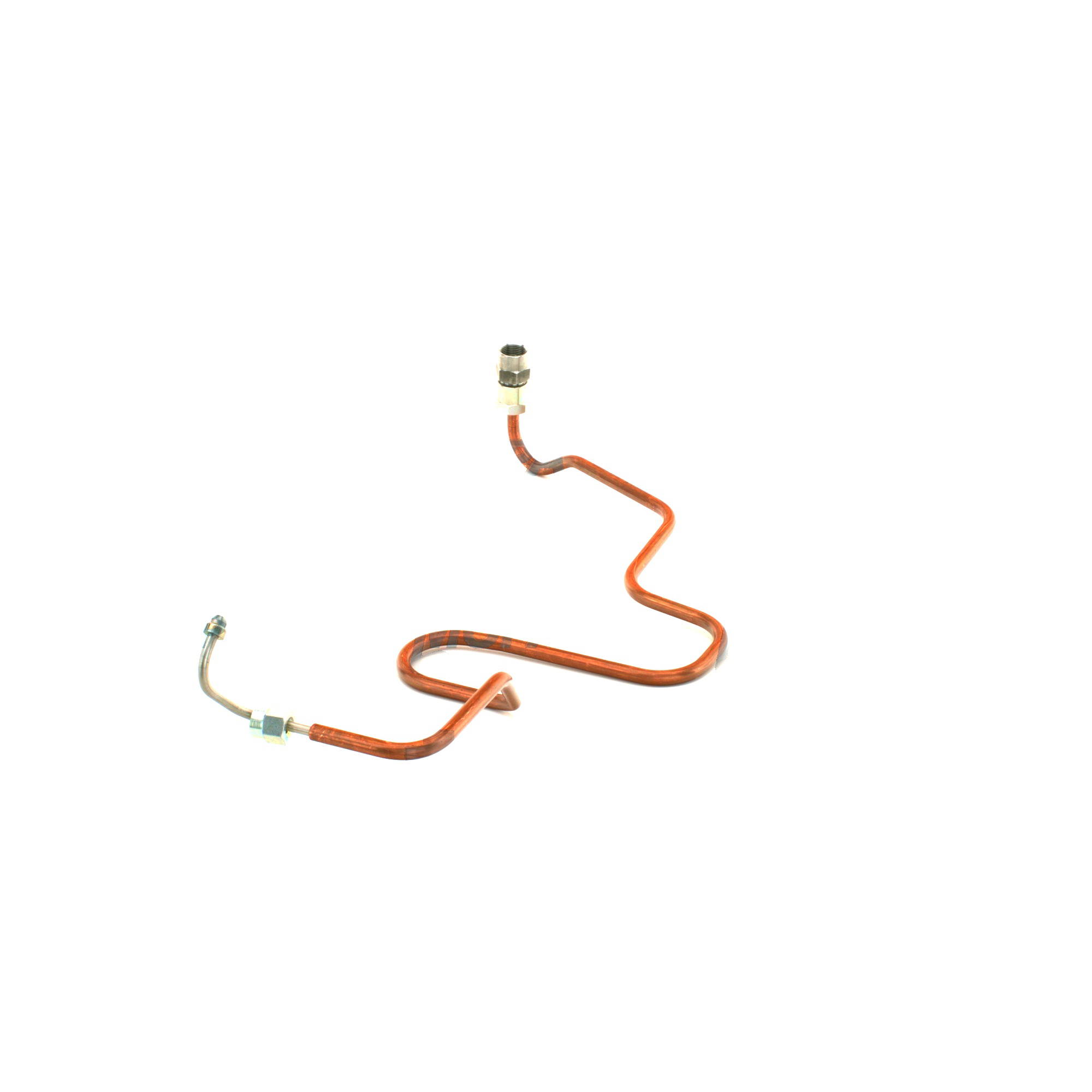

PRESSURE LINE and Lines and pipes for marine and diesel engines

Lines and pipes are the circulatory system of every engine, transporting fuel, lube oil, coolant, hydraulic fluid, charge air, and—in gas engines—combustible gas with precision and safety. Within this category, the PRESSURE LINE is the critical element that carries fluids at elevated pressures between pumps, rails, injectors, coolers, and actuators. In marine engines and industrial diesel engines alike, correctly engineered lines and pipes maintain stable operating conditions, protect equipment, and underpin reliable, efficient performance across the vessel’s duty profile.

Whether fabricated from seamless alloy steel, stainless steel, or corrosion‑resistant CuNi for seawater environments, these components are engineered to withstand pressure, vibration, temperature, and chemical exposure. Their geometry—wall thickness, bend radius, end form, and fitting interface—must be exact so that pressure losses are minimized, pulse loads are controlled, and leak-tight connections are maintained over long service intervals.

Technical function of Lines and pipes and the PRESSURE LINE in engines

In an engine, Lines and pipes provide defined flow paths and stable pressure to critical subsystems. A PRESSURE LINE in a diesel engine typically links a high-pressure pump to a common rail or directly to injectors, carrying fuel at hundreds to well over a thousand bar. In a marine engine, a PRESSURE LINE may also feed lube oil galleries, hydraulic valve actuators, or turbocharger control circuits. Charge‑air pipes and coolant pipes manage airflow and thermal balance, while gas lines in dual‑fuel and gas engines deliver precisely metered fuel under monitored pressure.

Performance depends on the integrity of these conduits. Smooth internal surfaces and correct diameters prevent turbulence and pressure drop; pulsation dampers and accumulators integrate with lines to reduce pressure peaks; rigid supports and clamps prevent fretting and fatigue. Proper end connections—such as DIN/ISO bite‑type, flare, or double‑ferrule designs—ensure repeatable, leak‑free joints. When selecting PRESSURE LINE OEM parts, the pressure class, material, and end‑form specification must match the engine maker’s requirement to maintain injection timing accuracy, lubrication film stability, and cooling flow even under dynamic load.

- · Precise routing maintains flow and reduces pressure loss.

- · High burst safety factors protect against transient spikes.

- · Corrosion‑resistant materials suited to marine environments.

- · Vibration‑resistant clamps and brackets limit fatigue.

- · Tight dimensional tolerances secure leak‑tight connections.

- · Cleanliness standards safeguard injectors and bearings.

- · Compatible with recognized DIN/ISO/SAE fitting systems.

- · Thermal stability for sustained high‑temperature operation.

PRESSURE LINE routing, pulsation control, and safety

Routing is not cosmetic—it is functional engineering. Correctly bent Lines and pipes maintain minimum bend radii to preserve cross‑section, avoid chafe points, and allow thermal growth. In fuel systems, the PRESSURE LINE diesel engine arrangement often uses matched-length runs to equalize injection timing between cylinders. For marine engine safety, double‑walled fuel lines with leak‑off detection are used around hot surfaces, confining any spray and directing it to a monitored drain. These details reduce fire risk and stabilize performance under varying load and sea states.

Material selection for Lines and pipes in marine engines

Material choice follows the medium and environment. Stainless steel resists corrosion in fuel and lube systems, while CuNi alloys serve seawater cooling circuits. For very high pressures, seamless quenched‑and‑tempered steels offer the required yield strength. Surface treatments and protective sleeves add abrasion and thermal protection, and preformed ends ensure consistent sealing at specified torque.

Importance for engine reliability and service life

Lines and pipes directly influence uptime and lifecycle cost. Any loss of integrity in a PRESSURE LINE marine engine application can lead to immediate issues: fuel spray and fire hazard, sudden power loss due to rail pressure collapse, injector misfire from aeration, or bearing damage from lube‑oil starvation. Coolant pipe failures trigger overheating, cylinder head stress, and potential cracking. Minor weeps can introduce air, corrode fittings, and degrade performance long before a visible leak is noticed.

Over time, vibration and thermal cycles can cause work‑hardening at bends, clamp fretting, or seal relaxation at fittings. Using the correct components, torque values, and support spacing is essential. Routine inspection focuses on chafe marks, discoloration from weeping, clamp condition, and secure routing. Replacing fatigued or out‑of‑spec Lines and pipes prevents unplanned stoppages, environmental incidents, and class non‑conformities.

Advantages of OEM spare parts suitable for Lines and pipes

OEM spare parts suitable for Lines and pipes preserve the engineered performance of the engine. They are built to the exact material grade, wall thickness, pressure rating, end‑form, and bend geometry defined for the specific model. This precision sustains injection stability, lube‑oil pressure, and coolant throughput while ensuring compatibility with existing clamps, brackets, and mating hardware.

From a performance and reliability standpoint, PRESSURE LINE OEM parts help maintain target rail pressure dynamics, reduce micro‑leak risks, and deliver consistent sealing at specified torques. From a budget perspective, the right fit first time reduces installation hours, repeat interventions, and collateral damage to adjacent equipment. Over the service life, proper metallurgy and dimensional control resist corrosion, fatigue, and creep, extending maintenance intervals and protecting critical components such as injectors, pumps, bearings, and turbochargers.

Why specify OEM spare parts for PRESSURE LINE and Lines and pipes

Traceability, documented test regimes, and adherence to the engine maker’s drawings are central advantages. Cleanliness levels protect precision components downstream. Correctly formed ends and calibrated lengths prevent undue stress, while validated pressure classes match real operating spikes—including cold starts and rapid load changes. For dual‑fuel and gas engines, OEM spare parts maintain the safety envelope for gas supply Lines and pipes, ensuring tight shut‑off and monitored leak‑off compatibility.

MOPA — your partner for OEM spare parts Lines and pipes

MOPA supplies OEM spare parts for Lines and pipes with a focus on speed, quality, and security in the trade of OEM parts for diesel and gas engines. Our team cross‑references engine models, part numbers, and technical revisions to deliver PRESSURE LINE assemblies and pipe sets that fit and perform as specified. We support purchasers and shipowners with rapid quotations, short lead times, and logistics solutions tailored to port calls and dry‑dock schedules.

Every delivery is prepared for engine‑room readiness: protective caps to maintain cleanliness, clear labeling by cylinder/position, and documentation for class or shipboard records on request. From fuel injection line sets and lube‑oil pipes to coolant and charge‑air conduits, MOPA provides the components and technical clarity needed to keep fleets efficient, compliant, and safe.

Conclusion

Lines and pipes—especially each PRESSURE LINE—are foundational to the performance, efficiency, and safety of marine and diesel engines. Their correct design and condition directly affect pressure stability, thermal control, and reliability. By choosing OEM spare parts suitable for Lines and pipes, operators safeguard uptime, protect critical components, and optimize lifecycle costs with components that fit, seal, and last as intended.