PRESSURE PIPE solutions for Lines and pipes in marine and diesel engines

Lines and pipes are the circulatory system of an engine. As rigid or semi-rigid conduits, they route fuel, lube oil, coolant, charge air, and hydraulic media precisely where they are needed. In heavy-duty diesel and gas engines—whether in a vessel’s engine room or a power plant—this category includes fuel injection lines, cooling water pipes, lubrication oil lines, pneumatic and hydraulic tubes, and sensor impulse lines. Built from precisely formed, pressure-rated tubing with reliable connection interfaces, Lines and pipes are fundamental to safety, efficiency, and uptime. The PRESSURE PIPE is the most critical subset for high-pressure fuel delivery and other demanding circuits, and it must meet tight tolerances and proven test criteria to perform under harsh thermal and vibratory loads.

Technical function of Lines and pipes: PRESSURE PIPE in a diesel engine

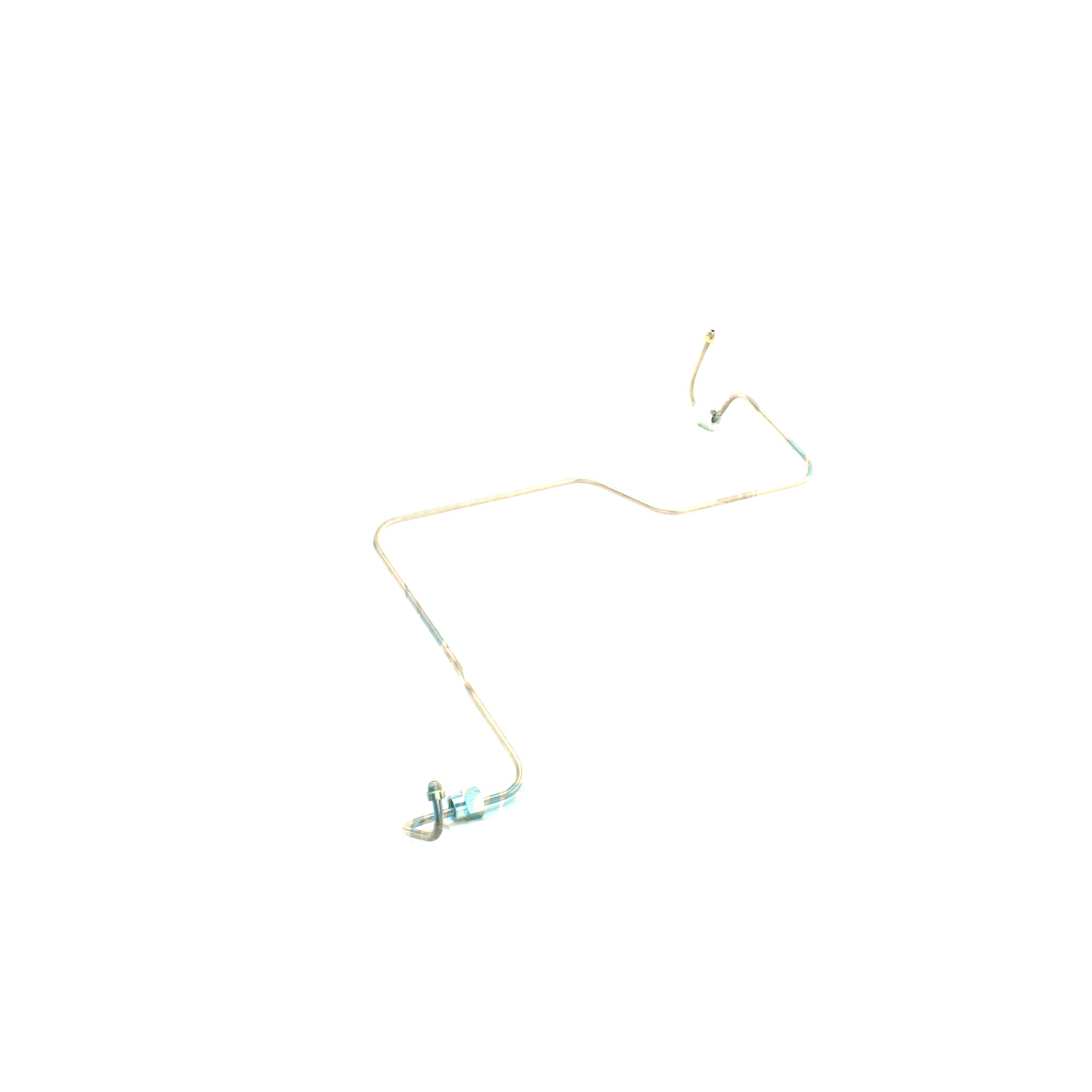

Within an engine, Lines and pipes ensure controlled media flow with minimal losses, stable pressure, and safe containment. A PRESSURE PIPE in a diesel engine connects the high-pressure pump or rail to each injector, transmitting pulsed fuel at pressures that can exceed 1,500–2,000 bar. Its wall thickness, material grade, and internal finish are engineered to manage pressure waves, resist fatigue from cyclical loading, and prevent micro-leaks that would disturb injection timing and atomization.

In a marine engine, other Lines and pipes carry cooling water through jackets and heat exchangers to stabilize temperatures under continuous heavy load. Lubricating oil pipes distribute filtered oil to bearings and valve gear, maintaining a protective film and removing heat. Charge-air and intercooler pipes provide consistent boost levels with low pressure drop. Hydraulic and pneumatic lines actuate controls, while instrument impulse lines transmit accurate pressure signals for monitoring and protection systems. Across all these circuits, bend geometry, clamping, and routing are carefully defined to limit vibration, avoid chafing, and maintain service access.

For high-reliability fleets, PRESSURE PIPE OEM parts are built from traceable, specification-compliant materials such as seamless precision steel or corrosion-resistant stainless grades. Manufacturing typically includes controlled bending, end forming (flare, cone, or swage), and qualified joining interfaces (e.g., DIN/ISO compression or flanged connections). Hydrostatic and non-destructive tests verify integrity, and protective coatings or passivation improve resistance to salt-laden atmospheres on board.

- · High pressure rating matched to system specification.

- · Corrosion-resistant materials and protective finishes.

- · Precision bends and consistent ovality for repeatable fit.

- · Vibration-optimized routing with proper clamps and supports.

- · Cleanliness control to protect injectors, valves, and bearings.

- · Qualified end connections for leak-free assembly.

- · Tested for burst, proof pressure, and dimensional tolerances.

- · Documentation and material traceability for compliance.

Importance for engine operation: PRESSURE PIPE and long-term reliability

Engine performance depends on stable flow and pressure. A compromised PRESSURE PIPE in a diesel engine can cause poor atomization, hard starting, elevated fuel consumption, and increased smoke due to disturbed injection events. Micro-cracks from vibration or incorrect clamping can propagate into leaks, creating fire hazards on marine engines and leading to unplanned downtime. Losses in cooling water pipes raise metal temperatures, reducing component life. Lubricating oil line blockages or leaks rapidly escalate into bearing distress and potential seizure.

Corrosion—especially pitting and crevice corrosion in marine environments—weakens tube walls and fittings. Chafing against adjacent components, over-tightened flare connections, and use of non-matching fittings are common root causes of failures. Routine inspection should look for dampness at joints, discoloration, bulging, clamp imprinting, and unsupported spans. Preventive replacement of aged Lines and pipes, especially high-duty PRESSURE PIPE assemblies on marine engine fuel systems, is vital for safety, emissions compliance, and predictable service intervals.

Advantages of OEM spare parts suitable for Lines and pipes and PRESSURE PIPE

Selecting OEM spare parts suitable for Lines and pipes ensures each pipe’s geometry, metallurgy, and pressure rating match the engine’s design intent. Bend radii, end forms, and ferrule types align precisely with mating components, reducing installation time and minimizing the risk of assembly-induced stress. Tube cleanliness and surface finish protect sensitive injectors and control valves from particulate damage. Pressure testing and process controls deliver consistent performance from delivery to commissioning.

Beyond technical fit, the operational advantages are substantial. Downtime is shortened by drop-in compatibility and correct clamping points. Lifecycle costs decrease because materials and coatings resist corrosion and fatigue, extending service intervals. Documentation packages, including material certificates and dimensional reports, support class and flag requirements in marine service. For fleets running mixed platforms, standardized PRESSURE PIPE solutions across engine families help consolidate inventory and simplify logistics, while maintaining the performance envelope specified by the engine designer.

In short, PRESSURE PIPE for marine engine applications and other critical Lines and pipes perform best when sourced as OEM parts that reflect validated engineering, controlled manufacturing, and application-specific testing.

MOPA: your fast, quality-focused, and secure OEM partner for Lines and pipes

MOPA is an experienced and reliable partner for OEM spare parts suitable for Lines and pipes, including high-pressure fuel PRESSURE PIPE assemblies. We combine technical understanding of diesel and gas engines with responsive sourcing to deliver the right pipe set, on time and with full traceability. Our network enables fast turnaround on standard and engine-specific geometries, complete with correct fittings, clamps, and protective caps to maintain cleanliness during transit.

Working with MOPA means streamlined quotations, clear documentation, and careful export handling. We prioritize quality and security in the trade of OEM parts for diesel and gas engines—so purchasers, shipowners, and technical decision-makers can count on consistent performance, predictable costs, and compliant deliveries across global operations.

PRESSURE PIPE sourcing for marine engine and power generation fleets

Whether you need single injector lines, full pipe sets, cooling water spools, or lube oil manifolds, MOPA supports fleet standards and project-specific requirements. From dimensional verification to material certification and packaging, we focus on details that keep engines operating safely and efficiently.

Conclusion: PRESSURE PIPE and Lines and pipes that protect performance

Lines and pipes—especially every PRESSURE PIPE in the fuel system—are vital to engine efficiency, safety, and service life. Specifying OEM spare parts suitable for this category delivers precise fit, proven pressure capability, and dependable reliability. With MOPA as your partner, you secure fast, quality-driven supply for diesel and gas engine applications worldwide.