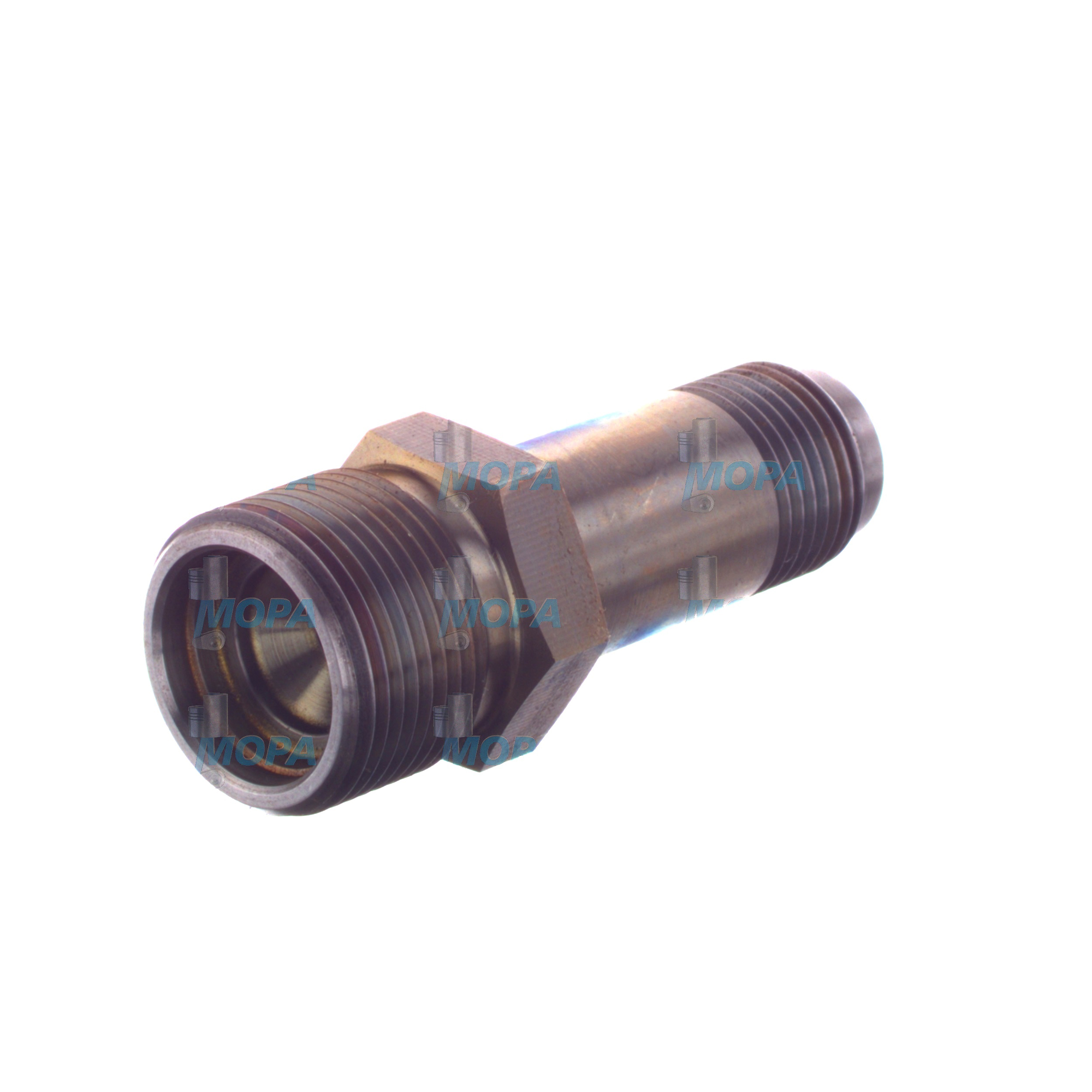

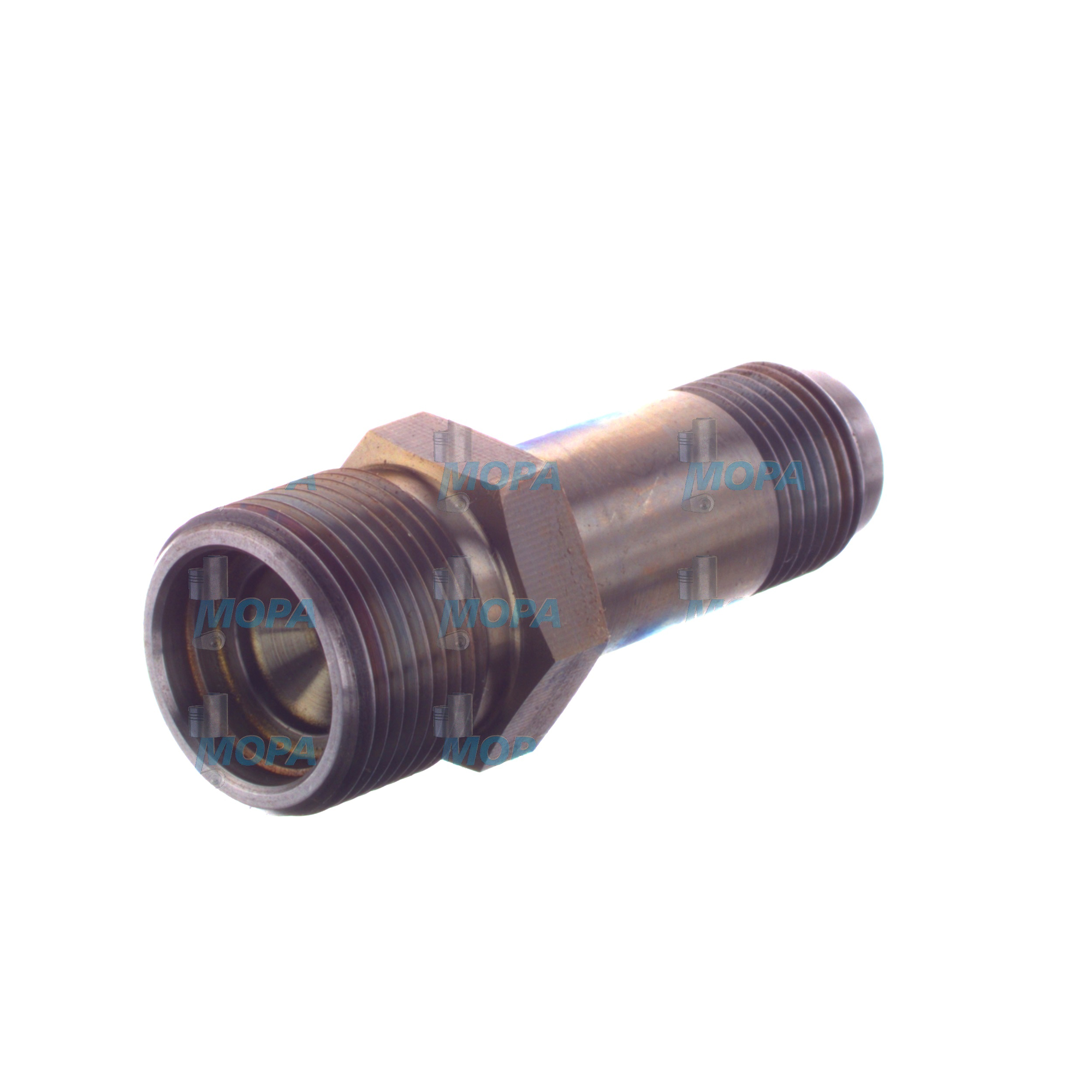

PRESSURE PIPE NECK in Lines and pipes for diesel and marine engines

Lines and pipes are precision-engineered conduits that route vital media—fuel, lubricating oil, coolant, charge air, and hydraulics—throughout an engine. In high-output diesel and gas units, especially aboard ships and in power generation, these components operate under extreme pressure, temperature, and vibration. Within this category, features such as the PRESSURE PIPE NECK are decisive for safe sealing, stress control at connections, and reliable distribution of fluids. Selecting the right lines and pipes protects the engine core, stabilizes performance, and reduces operational risk.

From common-rail fuel injection pipes to double-walled fuel oil lines, from seawater-resistant cooling pipes to high-integrity lube oil manifolds, each application imposes specific pressure ratings, corrosion resistance, and dimensional tolerances. A robust PRESSURE PIPE NECK diesel engine configuration reduces pulsation, ensures leak-tight couplings, and helps maintain precise injector timing, directly influencing efficiency and emissions.

Technical function of Lines and pipes with PRESSURE PIPE NECK in marine engine and diesel engine

In fuel systems, lines and pipes transfer pressurized fuel from the high-pressure pump or rail to each injector. The internal diameter, wall thickness, and bend radii are tuned to damp pressure waves and sustain injection pressure—often well above 1,500 bar in modern common-rail systems. The PRESSURE PIPE NECK is a localized geometry at the pipe end or coupling seat that manages force distribution, supports sealing surfaces, and mitigates stress concentration under cyclic loads. In practice, this small section stabilizes the joint, reduces fretting, and helps maintain consistent injection events under vibration typical of a marine engine.

On lube oil circuits, pipes feed bearings, camshafts, and turbochargers at controlled pressure. Dimensional accuracy and surface finish reduce pressure drop and cavitation risk, while proper clamping intervals limit vibration-induced fatigue. Cooling water pipes—often fabricated from stainless steel or CuNi alloys for seawater exposure—must resist corrosion and erosion. Charge-air pipes demand smooth bores and stable joints to preserve turbocharger efficiency and intercooler performance. Across all circuits, PRESSURE PIPE NECK OEM parts are engineered to seat correctly with flared, flanged, or compression fittings (e.g., DIN/SAE systems), ensuring repeatable torque, sealing integrity, and service accessibility.

Materials, standards, and testing for PRESSURE PIPE NECK OEM parts

Lines and pipes are typically produced from seamless precision steel tubing (e.g., EN 10305), stainless grades for corrosion resistance, or CuNi alloys in maritime service. Surface treatments such as zinc-nickel, phosphating, or passivation enhance durability. Quality controls include dimensional inspection, hydrostatic testing at elevated pressures, and documentation such as 3.1 material certificates. Routing adheres to best practice—expansion loops to absorb thermal growth, isolation from hot surfaces, and clamp spacing that prevents resonance and fretting.

- · High-pressure capability for common-rail injection up to extreme service ranges.

- · Corrosion-resistant alloys suitable for marine environments and varied fuels.

- · Precision bends with controlled ovality for low pressure loss.

- · Leak-tight joints via flared, flanged, or compression connections.

- · Vibration-optimized routing and double-walled options for safety.

- · Thermal management using shields, supports, and expansion allowances.

- · Traceable manufacturing and pressure-testing documentation.

Importance for engine operation and service life

Reliable lines and pipes are critical to engine uptime and safety. Degradation can arise from cyclic fatigue at bends or clamp points, local overheating, corrosion pitting (especially in salt-laden atmospheres), or erosion from particulate-laden fluids. At the joint, micro-cracks or fretting at the PRESSURE PIPE NECK can propagate under pulsating pressure, eventually causing leaks or sudden failures. In fuel systems, even small leaks compromise injection pressure, leading to poor atomization, increased smoke, and power loss—while larger leaks create a severe fire hazard. In lube oil circuits, pressure loss accelerates wear of bearings and turbochargers. In cooling circuits, pinholes or joint failures raise operating temperatures and trigger shutdowns.

Operationally, the consequences include unplanned stops, bilge contamination, class non-compliance, and costly repairs. Routine inspection should focus on clamp spacing, chafe protection, and discoloration indicating overheating. Non-destructive tests—dye penetrant at known stress points, borescope checks, and periodic hydro tests—help identify early-stage defects. Torque verification at fittings, replacement of aged vibration isolators, and adherence to engine-maker service intervals substantially extend service life.

Advantages of OEM spare parts suitable for Lines and pipes

OEM spare parts suitable for Lines and pipes offer consistent metallurgy, geometry, and heat treatment aligned with the engine’s design envelope. Tightly controlled bore tolerances and bend radii preserve intended flow characteristics, pressure dynamics, and injection timing. Correct seat profiles at the PRESSURE PIPE NECK ensure predictable tightening torque and sealing behavior, minimizing rework and leakage risk. Coating systems and material selections are specified for diesel, gas, and heavy fuel applications, supporting long-term corrosion resistance and clean internal surfaces.

From a budget and uptime perspective, precise fitment reduces installation hours, avoids iterative adjustments, and mitigates the chance of reoccurring leaks that lead to downtime. Documentation, traceability, and standardized testing simplify audits and help maintain regulatory compliance. Choosing PRESSURE PIPE NECK OEM parts for a diesel engine or a PRESSURE PIPE NECK marine engine application safeguards performance, reliability, and lifecycle costs across main engines and auxiliary gensets.

MOPA as a partner for OEM spare parts Lines and pipes

MOPA is an experienced, reliable partner for OEM spare parts Lines and pipes. We combine speed, quality, and security in the trade of OEM parts for diesel and gas engines. Our team supports part identification from engine serial numbers and drawings, consolidates kitted deliveries for maintenance windows, and provides pressure-test and material documentation where required. Global logistics, careful packaging for sensitive pipe geometries, and responsive lead-time management ensure your engine returns to service swiftly.

Whether you need high-pressure fuel pipes with a defined PRESSURE PIPE NECK, lube oil manifolds, or seawater-resistant cooling pipes, MOPA streamlines sourcing with technical clarity and dependable execution. From quotation to dispatch, you benefit from consistent communication, verified specifications, and risk-aware handling that protect both schedule and engine integrity.

Conclusion: PRESSURE PIPE NECK and Lines and pipes

Lines and pipes—down to critical features like the PRESSURE PIPE NECK—directly influence engine performance, safety, and longevity. Correctly engineered, installed, and maintained components keep pressure stable, leaks at bay, and efficiency on target. OEM spare parts suitable for Lines and pipes provide the dimensional accuracy, materials, and documentation required to maintain reliability and control lifecycle costs across diesel and marine applications.