CORE PLUG HOLE locking parts for marine and diesel engines

Locking parts are the small but decisive mechanical elements that secure, align, and seal assemblies across the engine. From retaining rings, tab washers, and lock plates to dowel pins, keys, split pins, and sealing plugs for a CORE PLUG HOLE, these components keep critical interfaces tight and precisely positioned. In high-output diesel and gas engines—especially in marine environments—locking parts prevent micro-movements, maintain geometry under load, and protect fluid circuits. The result is stable performance, safer operation, and predictable maintenance windows.

Technical function of locking parts and CORE PLUG HOLE components

In an engine, locking parts disable unintended movement. Dowel pins and keys fix spatial alignment between housings and rotating members so timing and gear meshing remain exact. Retaining rings, circlips, and tab washers hold bearings, gears, and pulleys in axial position despite vibration and thermal cycling. Lock plates with bendable tabs provide a positive mechanical stop for bolts subject to fluctuating torque. Cotter pins and safety wire deliver visual, tamper-evident security for critical fasteners.

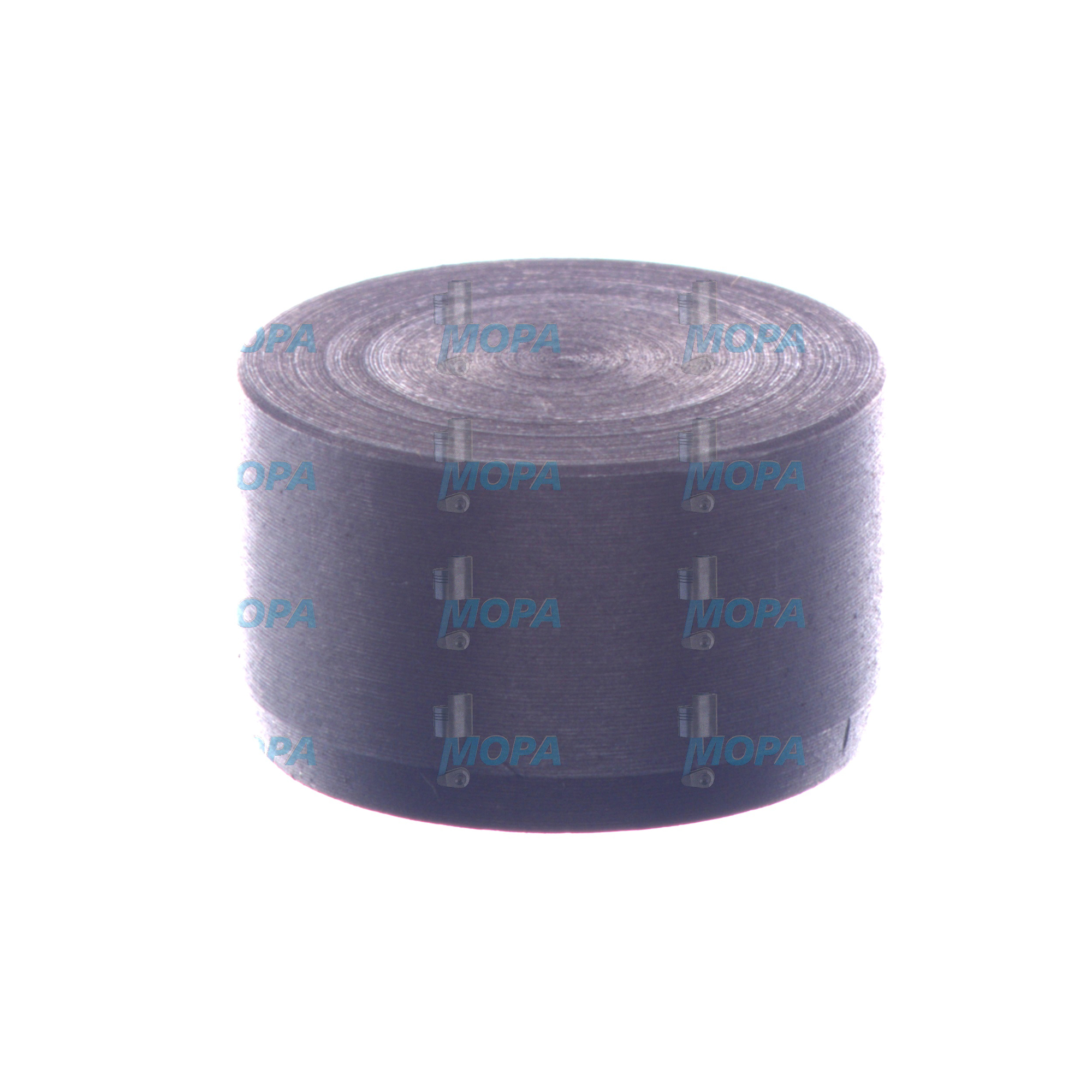

Sealing plugs—especially those installed in a CORE PLUG HOLE—close casting and gallery openings in the block and cylinder head. A CORE PLUG HOLE in a diesel engine is a manufacturing access point that must be sealed to keep the coolant jacket or oil galleries leak-free. Properly sized and seated plugs use an interference fit that holds even under pressure pulses and temperature swings. In large-bore marine engine platforms, the design and finish of the CORE PLUG HOLE and the plug’s cup geometry directly influence leakage resistance and long-term corrosion behavior. When sourced as OEM parts, material composition, hardness, and coating systems are consistent and traceable, which is essential for repeatable sealing performance.

- · Secure precise alignment of housings and rotating groups

- · Maintain axial retention of bearings, gears, and pulleys

- · Lock bolted joints against loosening under vibration

- · Seal coolant and oil circuits via CORE PLUG HOLE and gallery plugs

- · Resist corrosion and fretting through suitable materials and coatings

- · Enable fast, confident service inspections and replacements

CORE PLUG HOLE in a marine engine: sealing specifics that matter

Marine duty cycles impose long periods at constant load, salt-laden atmospheres, and frequent thermal gradients. For a CORE PLUG HOLE in a marine engine, that means the plug must combine exact dimensional control with corrosion protection. Typical solutions include carbon steel plugs with phosphate or zinc-flake coatings, and stainless options for brackish or seawater-exposed applications. The hole finish, cleanliness, and press depth are as important as the plug itself. A gently radiused entry, verified diameter tolerance, and correct interference deliver a stable seal; improper fit can lead to slow seepage, sudden blowout, or galvanic attack around the seat.

Importance for engine operation and service life

Locking parts underpin reliability. If a dowel pin wears or a key frets, alignment shifts, causing gear whine, accelerated bearing wear, or timing drift. A failed retaining ring can allow axial migration of a component, culminating in contact damage or catastrophic seizure. Most critically, a compromised CORE PLUG HOLE seal can vent coolant, causing rapid overheating, head gasket failure, or localized hot spots that crack liners or heads. In propulsion and power-generation contexts, such issues translate directly into unplanned downtime, towing costs, and lost revenue.

Because these parts are inexpensive relative to the assemblies they protect, they are often refreshed during overhauls. The decisive factor is quality consistency: dimensional tolerances that fit first time, surface finishes that prevent fretting, and materials that retain spring or clamping force across thousands of thermal cycles. Selecting robust locking parts extends service intervals and stabilizes performance metrics like fuel efficiency, lube-oil condition, and vibration signatures.

Advantages of OEM spare parts suitable for locking parts and CORE PLUG HOLE plugs

OEM spare parts suitable for locking parts are engineered to the same specifications as the engine platform. That means reliable fits, predictable installation force, and validated retention or sealing behavior. For the CORE PLUG HOLE in a diesel engine, OEM spare parts ensure the correct cup depth, wall thickness, and coating, minimizing the risk of micro-leaks and corrosion under the lip.

From a budget perspective, these components pay for themselves by reducing rework, repeat leak tests, and early replacements. From a performance standpoint, correct spring characteristics in rings and washers preserve clamp loads, while precision keys and dowels safeguard timing accuracy and bearing life. Lifecycle documentation, lot traceability, and consistent metallurgy provide the confidence that each replacement behaves like the last—critical for fleets and classed vessels.

Key reasons to choose OEM spare parts suitable for locking parts:

- · Tight tolerances for repeatable press-fit and alignment

- · Materials and heat treatment matched to engine duty

- · Coatings that combat corrosion in marine environments

- · Proven retention forces and sealing performance

- · Reduced downtime through right-first-time installation

- · Lot traceability to support quality and compliance

MOPA – your partner for OEM locking parts and CORE PLUG HOLE components

MOPA supplies OEM parts for diesel and gas engines with a focus on speed, quality, and security in every transaction. Purchasers and shipowners rely on MOPA for rapid quotation, accurate cross-referencing, and consolidated deliveries that keep maintenance windows short. Whether you need a full kit of locking parts for a major overhaul or a specific CORE PLUG HOLE plug for a marine engine, MOPA provides vetted components, clear documentation, and dependable lead times.

Our team understands the criticality of small components in large machinery. We help specify the correct material and coating combinations for your operating profile, align shipments with dry-dock schedules, and ensure the OEM parts you receive integrate seamlessly into your maintenance standards.

Conclusion on locking parts and CORE PLUG HOLE

Locking parts are fundamental to engine integrity, and the CORE PLUG HOLE is a prime example where precise sealing protects performance and uptime. Choosing OEM spare parts suitable for locking parts secures alignment, sealing, and retention—improving reliability, extending service life, and optimizing the budget across the entire maintenance cycle.