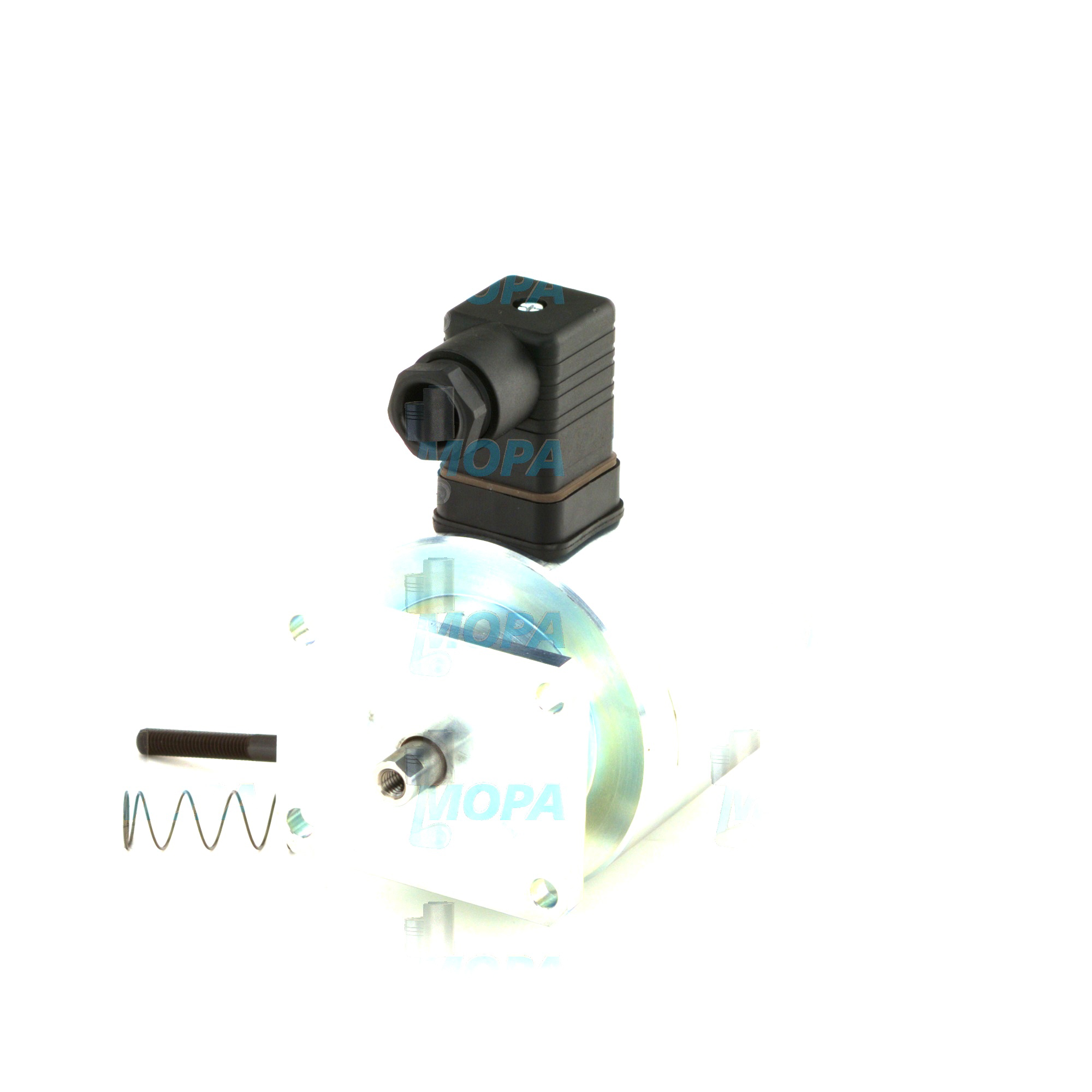

SOLENOID Magnets for Marine, Diesel and Gas Engines

Magnets are precision components that convert electrical energy into controlled magnetic force or provide stable magnetic fields for sensing. In engines, they sit at the core of SOLENOID assemblies, magnetic pickups, and permanent-magnet generators, ensuring that fuel shutoff, actuation, speed sensing, and power generation happen exactly when they should. Whether in a compact generator set or a large marine engine, the right magnet material and geometry underpin reliable control, safety, and efficiency.

As an article category, Magnets include permanent magnets (NdFeB, SmCo, ferrite) and magnet assemblies designed for high temperatures, vibration, and chemically aggressive environments. They are engineered for consistent flux density, tight dimensional tolerances, and corrosion protection—attributes that directly impact SOLENOID performance, sensor accuracy, and alternator output in demanding engine rooms.

Technical Function: Magnets and SOLENOID performance in a marine engine or diesel engine

In a SOLENOID diesel engine fuel shutoff or start/stop actuator, magnetic force is generated when the coil energizes, pulling an armature through a defined stroke. Magnets interact with this electromagnetic circuit in several ways: as permanent elements in latching SOLENOID designs (holding force without continuous coil power), as bias magnets stabilizing the armature position, or as critical flux “shunts” that shape the magnetic path for faster pull-in and controlled release. In sensors—such as magnetic pickups on flywheels or Hall-effect speed and timing sensors—precision magnets create a stable reference field that converts mechanical motion into a clean electrical signal.

Material selection is central. Neodymium (NdFeB) offers very high energy density for compact SOLENOID OEM parts, but must be specified with the right temperature rating and coating to prevent demagnetization and corrosion. Samarium Cobalt (SmCo) resists heat and oxidation better, making it a strong choice near turbochargers or exhaust manifolds. Ferrite is robust and cost-efficient for larger geometries and moderate temperatures. Geometry—arc segments, rings, blocks—and the air-gap design determine pull force, response time, and holding characteristics across the duty cycle.

In a SOLENOID marine engine environment, magnets also face salt mist, oil vapors, and constant vibration. Surface finishes such as Ni-Cu-Ni or epoxy, and encapsulated assemblies, protect against corrosion while maintaining flux. Correct pairing of magnet grade, coil Ampere-turns, and armature metallurgy yields predictable pull-in time, reduced chatter, and lower power consumption—vital in 24/7 power-generation sets.

- · High flux density for compact SOLENOID packages.

- · Heat-stable grades for elevated engine-room temperatures.

- · Corrosion-resistant coatings and encapsulation.

- · Tight tolerances for consistent air gaps and stroke.

- · Proven vibration resistance for marine and genset use.

- · Repeatable Gauss and coercivity for reliable sensing.

- · Optimized with coil specs for fast pull-in and release.

SOLENOID applications and sensing with Magnets in OEM parts

Common uses include diesel engine fuel shutoff SOLENOIDs, gas engine ignition and blowdown actuators, latching SOLENOIDs in safety interlocks, and speed or position sensing on crankshafts and camshafts. Permanent magnets inside alternators or PMGs support stable voltage output at varying RPMs, helping electronic controllers maintain efficient combustion and load response.

Why Magnets are critical for reliable engine operation

When magnets drift out of spec—through heat-related demagnetization, chipped edges, or coating failure—the effects cascade through the engine. A weakened latching SOLENOID may fail to hold, causing unexpected shutdowns or increased power draw. Sluggish armature movement raises pull-in time, delaying fuel control and degrading start performance. In sensor systems, reduced flux leads to noisy or unstable signals, resulting in erroneous RPM readings, mistimed injection, or protective trips. In generators, diminished magnet strength reduces output and forces controllers to operate at suboptimal points.

Conversely, well-specified magnets maintain consistent force over the full temperature range, ensure crisp actuation, and keep sensing thresholds stable, which supports precise timing, safer shutdowns, and reduced wear on mechanical components. Over the engine’s service life, this translates to fewer nuisance alarms, less unplanned downtime, and lower total cost of operation.

Advantages of OEM spare parts suitable for Magnets in SOLENOID systems

Selecting OEM spare parts suitable for Magnets ensures that magnetic properties, dimensions, and coatings match the engine maker’s specification. This is particularly important for SOLENOID diesel engine actuators and marine engine sensors, where minor deviations in Gauss level, coercivity, or air-gap dimensions can alter force curves and response times.

With OEM magnets and assemblies, purchasers gain predictable performance and simplified maintenance planning. Material traceability, documented thermal ratings, and validated coating systems reduce risk in aggressive environments. Precision manufacturing yields repeatable flux characteristics that align with the coil and armature design, protecting both performance and budget by preventing premature failures and avoiding costly troubleshooting offshore or on-site.

- · Verified material grades for consistent magnetic strength.

- · Dimensional fidelity for drop-in fit and correct air gaps.

- · Coatings validated for oil, fuel, and salt-laden atmospheres.

- · Stable performance across the specified temperature range.

- · Reduced downtime through predictable actuation and sensing.

- · Lower life-cycle cost via extended service intervals.

- · Compliance with SOLENOID OEM parts specifications.

MOPA: a reliable partner for OEM SOLENOID Magnets

MOPA supplies OEM parts for diesel and gas engines with a focus on speed, quality, and security in trade. For the Magnets category, MOPA supports SOLENOID applications, sensor systems, and generator assemblies with carefully selected OEM spare parts suitable for Magnets that meet engine specifications. Technical support helps match magnet grade and geometry to your SOLENOID coil and duty cycle, while robust logistics ensure rapid dispatch and dependable delivery worldwide.

From cross-referencing part numbers to providing documentation for marine compliance and industrial installations, MOPA streamlines procurement and minimizes risk. Purchasers and shipowners benefit from clear lead times, careful packaging, and consistent product quality that keeps engines performing as designed.

Conclusion

Magnets are foundational to SOLENOID actuation, sensing accuracy, and power generation in marine, diesel, and gas engines. Correctly specified materials and geometries deliver dependable force and clean signals under real-world conditions. Choosing OEM spare parts suitable for Magnets secures performance, reliability, and service life—supporting safe operation and protecting budgets across the engine’s lifetime.