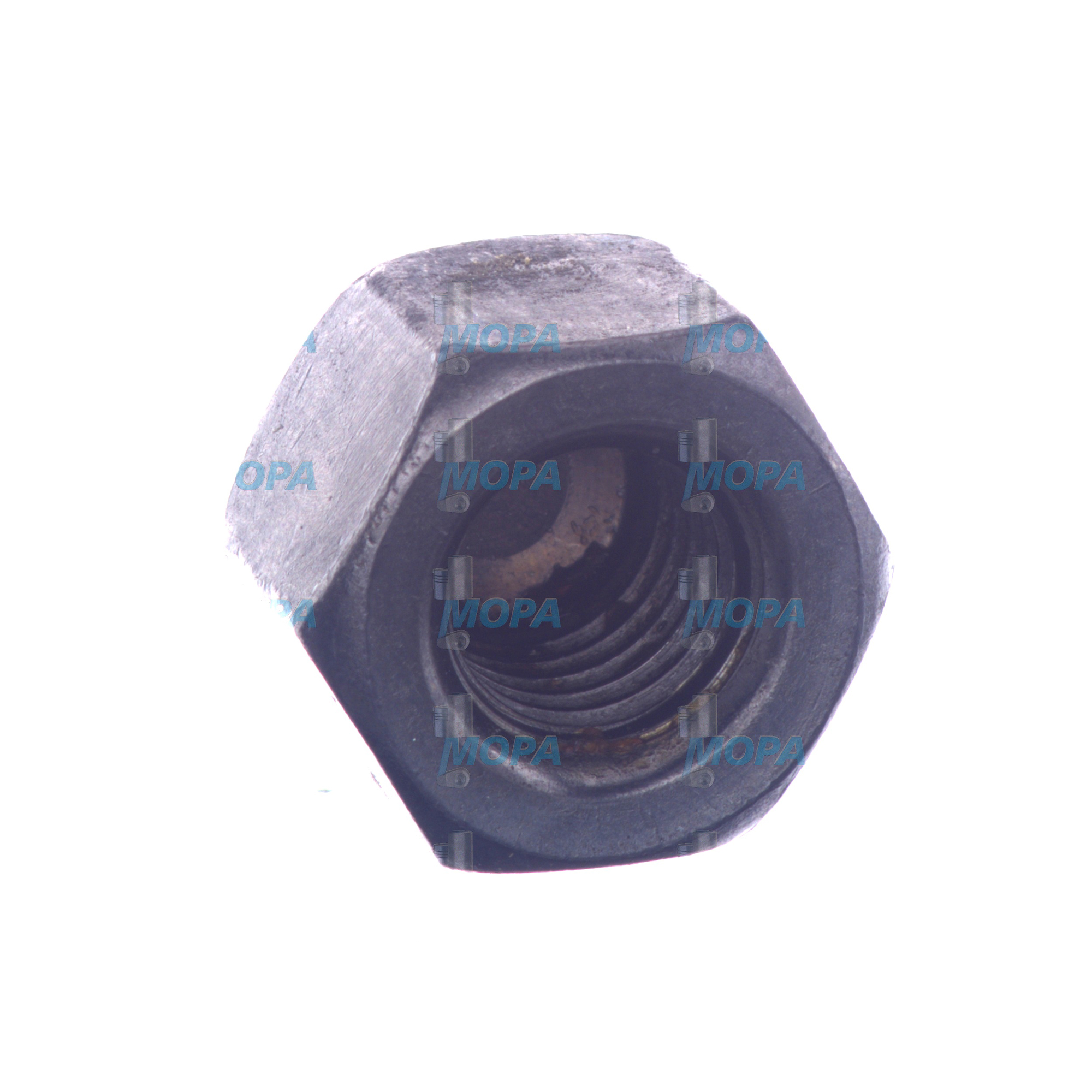

ACORN NUT solutions for high‑duty Nuts in marine and diesel engines

Nuts are precision fastening components that clamp engine subassemblies together, convert tightening torque into reliable preload, and keep joints stable under heat, vibration, and pressure. In heavy‑duty powertrains—whether a propulsion marine engine, a stationary power diesel engine, or a gas engine—Nuts are integral to the integrity of cylinder heads, main bearing caps, connecting rods, exhaust systems, turbochargers, and auxiliary equipment. While forms vary from hex to prevailing‑torque and cap designs, the role is the same: secure load paths and stable sealing surfaces so the engine delivers performance and uptime. Within this category, the ACORN NUT is often selected where a protective cap is required to shield exposed threads from corrosion, contamination, or accidental impact.

Technical function of Nuts in engines and the role of ACORN NUT in marine engine and diesel engine assemblies

An engine joint only performs as designed when the clamping force (preload) is sufficient and consistent throughout service. Nuts apply and maintain this preload by engaging with bolts or studs to generate axial tension. High‑strength materials and correct thread geometry ensure the nut can sustain cyclic loads without losing grip. Coatings and finishes control friction during tightening for predictable torque‑to‑tension conversion, while also defending against corrosion in salt‑rich marine atmospheres and high‑temperature zones around exhaust manifolds and turbochargers.

Where components have exposed studs—such as covers, guards, terminal boxes, or instrumentation housings—an ACORN NUT marine engine setup combines fastening and protection. The cap prevents ingress of dirt, oil mist, and spray, reduces snag risks for personnel, and preserves thread quality for future overhauls. In a diesel engine environment, ACORN NUT designs can also help mitigate corrosion onset at the thread run‑out, supporting consistent disassembly intervals and minimizing rework.

Critical to performance is the nut’s ability to resist self‑loosening. Designs include all‑metal prevailing‑torque types, deformed‑thread locknuts, and metal‑to‑polymer locking variants for lower‑temperature zones. On hot sections, all‑metal solutions with appropriate alloys and property classes are preferred to retain locking characteristics under thermal cycling. Standards frequently referenced include ISO 898‑2 for property classes (e.g., 8, 10, 12), ISO/UNC/UNF thread forms per engine maker specification, and DIN 1587 for cap (acorn) nuts. ACORN NUT OEM parts matched to the bolt/stud specification help maintain the intended joint stiffness and fatigue life.

Typical applications in powertrains

Nuts are used across engine main and auxiliary systems: cylinder head assemblies, main bearing caps, connecting rods, camshaft housings, exhaust manifolds and turbochargers, charge‑air coolers, flywheel and coupling flanges, engine mounts, and accessory brackets. ACORN NUT variants commonly protect exposed studs on covers and guards or finish assemblies in crew‑access areas on marine engine installations where safety and corrosion protection are paramount.

Key characteristics and advantages of Nuts

· High preload capacity through correct property class and thread fit.

· Stable torque‑tension behavior via controlled surface finish and coatings.

· Resistance to vibration‑induced loosening using locking geometries.

· Corrosion resistance tailored for marine atmospheres and hot sections.

· Compatibility with ISO/UNC/UNF threads as specified by engine makers.

· ACORN NUT cap design protects exposed threads and enhances safety.

· Traceable materials and heat treatment for predictable service life.

· Service‑friendly removal even after long intervals in harsh conditions.

Why Nuts are critical for engine reliability and service life

Insufficient or unstable clamping force leads to a cascade of problems: gasket blow‑by on heads and manifolds, fretting at bearing caps, misalignment of rotating assemblies, exhaust leaks that overheat nearby components, and eventual fatigue failure of fasteners. A nut that loses prevailing torque at temperature, suffers thread galling, or corrodes at the cap interface can force unplanned stops and expensive overhauls. Conversely, correctly specified Nuts maintain preload over thousands of duty hours, stabilizing sealing surfaces and joint stiffness. For safety, protected threads—often achieved with an ACORN NUT diesel engine configuration—reduce the risk of injury and make planned disassembly predictable. The net effect is longer service intervals, fewer re‑torques, and higher availability across the vessel or power plant.

Advantages of OEM spare parts suitable for Nuts and ACORN NUT

Using OEM spare parts suitable for Nuts preserves the engineered relationship between bolt, nut, washer, and joint surface. Dimensional accuracy in thread pitch diameter and nut height ensures the intended proof load is achieved without overstressing the fastener. Surface treatments specified by engine makers—such as zinc‑nickel, phosphate‑and‑oil, or high‑temperature coatings—deliver consistent friction coefficients so torque values yield the right clamp load. Material traceability and heat‑treatment verifications mean property classes behave as expected under cyclic stress and thermal gradients. For operators, this translates into predictable tightening, stable preload retention, and fewer joint‑related incidents.

From a budget perspective, the correct nut specification reduces rework, minimizes gasket and stud replacements caused by thread damage, and shortens outage time during overhauls. In terms of service life, pairing ACORN NUT OEM parts with the specified studs protects threads from corrosion, especially in saline air or splash zones, supporting repeatable maintenance cycles and safeguarding adjacent components.

MOPA as your partner for OEM spare parts Nuts and ACORN NUT

MOPA supplies OEM parts for diesel and gas engines with a focus on speed, quality, and security. For Nuts—including ACORN NUT solutions—MOPA provides rapid sourcing from vetted production lines, batch‑level traceability, and documentation aligned with engine‑builder specifications. Experienced technical support helps match thread forms, property classes, and coatings to your application, whether for a propulsion marine engine, auxiliary generator, or industrial power unit. Secure logistics, careful packing for corrosion control, and globally coordinated shipping keep downtime low and projects on schedule. Purchasers and shipowners value MOPA’s ability to consolidate multi‑brand OEM spare parts, simplify procurement, and uphold consistent fastener performance across fleets.

Conclusion

Nuts are foundational to engine integrity, converting torque into dependable clamping force and keeping joints secure under vibration and heat. ACORN NUT options add valuable thread protection and safety, especially in marine environments. Selecting OEM spare parts suitable for Nuts ensures fit, material consistency, and controlled friction behavior—supporting performance, reliability, budgets, and long service life across diesel and gas engine assets.