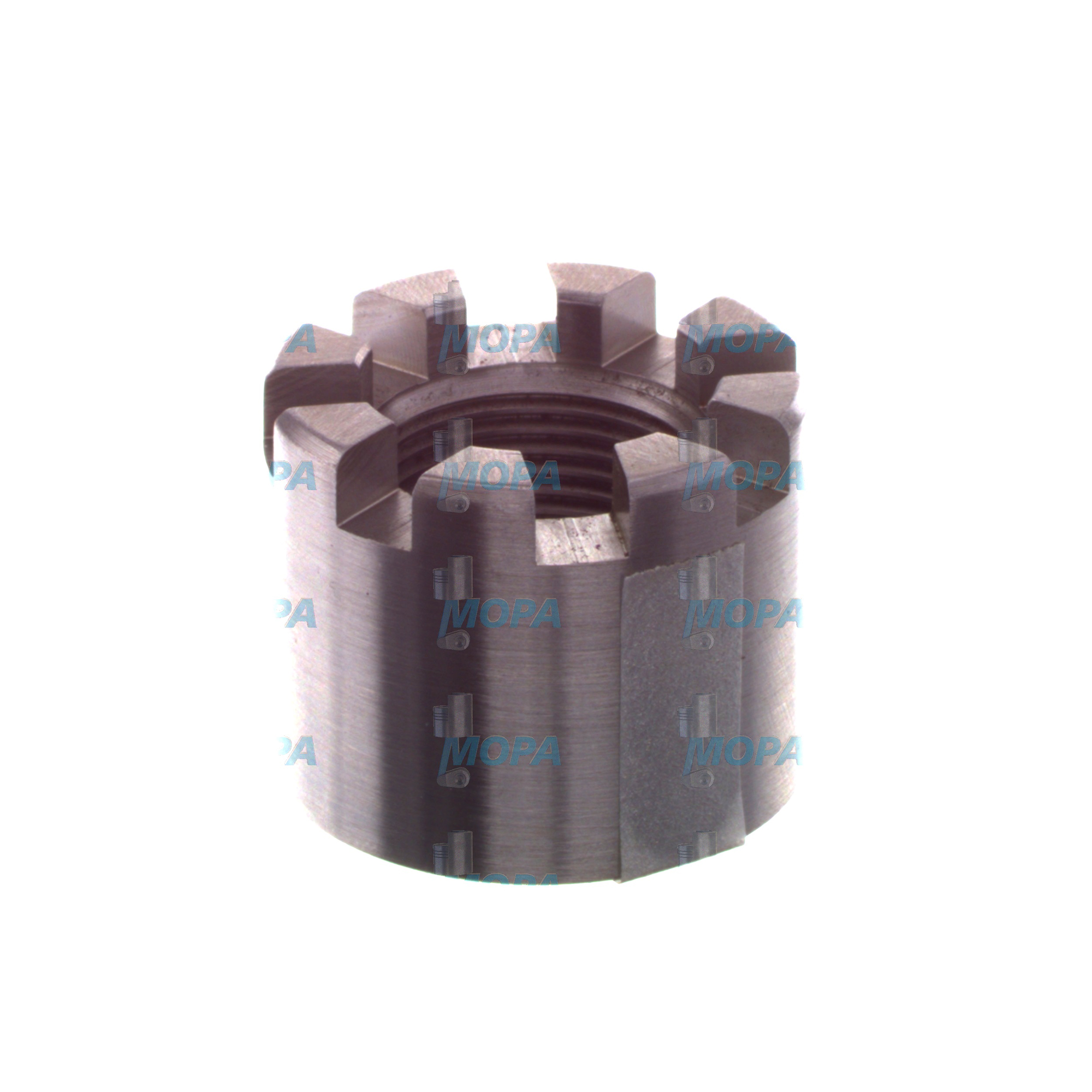

CASTLE NUT and Nuts for Marine and Diesel Engines

Nuts are precision fastening components that create secure, serviceable joints throughout engines and auxiliary systems. In high-output marine and diesel engines, nuts connect housings, brackets, covers, drive components, and safety-critical linkages. Within this category, the CASTLE NUT is a specialized locking nut featuring castellations that align with a drilled bolt or shaft and are secured with a cotter pin to prevent rotation. Whether used on governor linkages, actuator pivots, turbocharger brackets, or shaft-retained assemblies, correctly specified nuts protect performance, uptime, and safety by maintaining reliable clamp load under heat, vibration, and fluctuating loads.

Technical function of Nuts and CASTLE NUT in diesel engine and marine engine systems

Nuts work in tandem with bolts or studs to generate a defined preload, clamping components together so that the joint resists separation, shear, and micro-movement. In engines, this clamp load stabilizes alignments, seals gaskets, and preserves bearing clearances. A CASTLE NUT in diesel engine or marine engine linkages adds a mechanical lock: after reaching the required torque (and aligning the castellations with the fastener’s cross-hole), a cotter pin is inserted to block rotation. This positive locking method is preferred in dynamic joints where safety is paramount or where prevailing-torque nuts are unsuitable due to temperature, lubrication, or serviceability requirements.

Technically, the nut must deliver repeatable tension at the specified torque and retain frictional characteristics across thermal cycles. Material selection (e.g., alloy steel, stainless steel for marine exposure), hardness class, surface condition, and coatings directly influence torque-tension scatter and corrosion resistance. For high-temperature areas, nuts with appropriate tempering and metallurgical stability maintain strength and thread integrity. In salt-laden atmospheres, corrosion-resistant alloys or approved coatings are chosen to mitigate pitting, hydrogen embrittlement, and galling. For lock features, self-locking types rely on prevailing torque, while a CASTLE NUT provides visual confirmation of lock-up with the cotter pin—an advantage for routine inspections on propulsion and auxiliary engine systems.

- · Stable clamp load under vibration and thermal cycling

- · Options for mechanical locking, including CASTLE NUT with cotter pin

- · Material classes for high strength and temperature stability

- · Corrosion-resistant solutions for marine engine environments

- · Tight dimensional tolerances for accurate torque-tension results

- · Serviceable joints that support planned maintenance

Why Nuts and CASTLE NUT matter for engine reliability and service life

When a nut loses preload, joint surfaces begin to fret, seals deform, and alignment drifts. On engines, this can cascade into leakage at coolant, oil, or exhaust interfaces, accelerated wear of bearings due to housing distortion, or vibration-induced failures in accessories and instrumentation. A missing cotter pin on a CASTLE NUT can allow rotation and gradual back-off, turning a minor oversight into a critical failure on throttle linkages, fuel racks, or actuator arms. Thread damage, over-torqueing, and reuse beyond limits further compromise joint integrity. Consistently using the right nut type with the right locking method preserves tightening specifications, keeps gaskets compressed, and sustains shaft and bracket geometry—ultimately extending service intervals and protecting the powertrain from avoidable downtime.

Typical risks from worn or incorrect Nuts

Visible rounding of hex flats, deformed threads, loss of prevailing torque in locking nuts, heat tinting, or excessive corrosion are red flags. In high-load areas, underspecified nuts can strip or creep at temperature, while incompatible coatings can affect torque-tension predictions. In marine engine spaces, galvanic pairing and salt spray demand careful material compatibility; stainless grades or coated alloy steel are selected to balance strength and corrosion resistance. For CASTLE NUT applications, improper alignment with the drilled hole or reusing distorted cotter pins undermines the lock, defeating the purpose of the design.

OEM spare parts suitable for Nuts and CASTLE NUT OEM parts: performance, reliability, and budget

OEM spare parts suitable for Nuts ensure that metallurgy, heat treatment, dimensions, and coatings match the engine maker’s tightening data and service procedures. This alignment of specification to application produces predictable clamp load, consistent friction coefficients, and correct locking performance under real operating conditions. For a CASTLE NUT OEM parts selection, castellations are machined to precise profiles so the cotter pin seats correctly without under- or over-tightening the joint—critical for safety-related linkages on diesel and gas engines.

From a cost perspective, consistent quality reduces rework, retorque cycles, and premature gasket or bearing failures caused by preload loss. Traceable materials and documented compliance streamline audits and class requirements in marine operations. Standardized nut classes across fleets simplify inventory and training, while engineered coatings cut corrosion-driven maintenance in coastal and offshore environments. The result is better uptime and a lower total cost of ownership without compromising safety margins.

MOPA as a partner for OEM spare parts Nuts

MOPA is an experienced, reliable partner for OEM spare parts Nuts across diesel and gas engine platforms. We move fast on enquiries, provide quality-controlled sourcing, and package orders securely for global shipment. With technical cross-references, lot traceability, and documentation on request, MOPA supports safe, confident purchasing of nuts—including CASTLE NUT for marine engine and diesel engine assemblies—so your maintenance teams can execute with precision and speed. Our focus on speed, quality, and security in the trade of OEM parts keeps critical assets running and reduces downtime risk.

Conclusion: Nuts and CASTLE NUT in critical engine assemblies

Nuts are small components that deliver outsized impact on engine performance and safety. Where a mechanical lock is required, the CASTLE NUT adds proven security for marine engine and diesel engine linkages and shafts. Choosing OEM spare parts suitable for Nuts ensures consistent clamp load, corrosion resistance, and dependable locking—protecting uptime, budgets, and long service life.