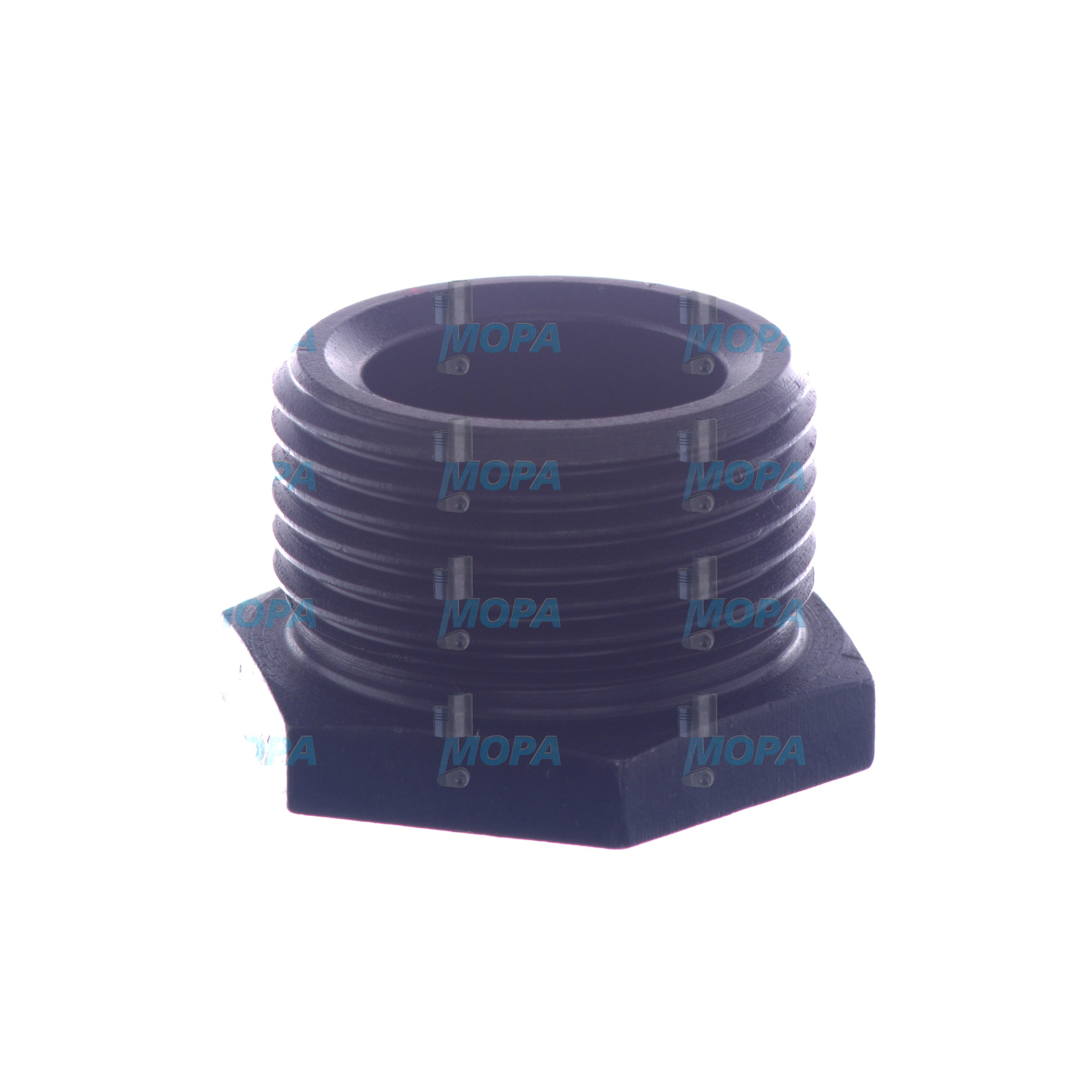

COLLAR NUT and high-performance Nuts for marine, diesel, and gas engines

Nuts are precision fasteners with internal threads that clamp critical joints throughout an engine. In combination with bolts or studs, they create the preload that holds cylinder heads, bearing caps, turbocharger housings, exhaust manifolds, mounts, and auxiliary systems together. Engine Nuts must resist vibration, thermal cycling, and corrosive environments while maintaining stable clamping force. Among these, the COLLAR NUT plays a key role wherever a broader bearing surface, precise axial location, or improved load distribution is required—typical in high-stress connections of marine and large diesel engines.

For shipowners and operators of power-generation assets, well-specified Nuts directly influence uptime, emissions compliance, and lifecycle cost. Material grade, thread quality, surface treatment, and locking concept determine whether a joint remains secure under shock loads and fluctuating temperatures. Selecting the right COLLAR NUT for marine engine assemblies or other all-metal Nuts for hot zones is essential to keep engines running reliably between planned overhauls.

Technical function of Nuts and the role of a COLLAR NUT in a diesel engine

Engine joints rely on controlled tightening to convert torque into preload. The nut’s thread geometry, friction characteristics, and face finish govern how consistently this preload is achieved and sustained. A COLLAR NUT in diesel engine applications integrates a flanged bearing face that spreads the clamping force over a larger area, reduces surface pressure, and helps prevent embedding or fretting on softer mating components. This design also improves alignment on shafts or studs and can reduce the need for separate washers—useful in tight spaces and high-vibration environments.

In practice, COLLAR NUT OEM parts are used on turbocharger connections, gear trains, pump drives, propeller shaft couplings, and injector or valve train fixtures where precise seating and repeatable torque-tension relationships are vital. All-metal prevailing-torque variants maintain clamp load at elevated temperatures, unlike polymer-insert locknuts that are unsuitable near exhaust or turbine casings. Surface coatings—such as phosphating or zinc flake—control friction coefficients for consistent tightening and add corrosion resistance in saline atmospheres common to marine operations.

- · High-strength steel grades for sustained preload under shock and vibration.

- · All-metal locking options for high-temperature zones.

- · Integrated collar/flange for stable seating and load distribution.

- · Precision threads (e.g., ISO 6H) for reliable fit with engine studs.

- · Heat treatment and metallurgy tuned for fatigue resistance.

- · Coatings that balance corrosion protection and stable friction.

- · Compatibility with torque-angle procedures used by engine makers.

- · Traceability for compliance and documentation requirements.

Importance of Nuts for engine reliability and service life

When Nuts lose preload—through thermal relaxation, vibration loosening, galling, or corrosion—joint integrity degrades. The result can be gasket leakage on cylinder heads and manifolds, misalignment in drivetrain components, hot-gas blow-by at turbocharger interfaces, or accelerated wear in bearings due to distorted housings. A compromised COLLAR NUT for marine engine applications may allow axial movement on splined shafts, leading to fretting, imbalance, and ultimately unplanned downtime.

Wear indicators include rounded flats, damaged threads, discolored surfaces from overheating, or seized nuts due to galling. Reusing deformed all-metal lock nuts or mixing thread classes increases the risk of inconsistent clamp load. Over-tightening is equally harmful; it can yield the stud or crush the joint, reducing fatigue life. Correct specification and replacement intervals for Nuts—matched to the engine family—are therefore critical to predictable overhauls and safe operation.

Advantages of OEM spare parts suitable for Nuts

Using OEM spare parts suitable for Nuts preserves the engineered relationship between torque, friction, and preload. Dimensional tolerances, material certificates, and surface finishes are aligned with the mating studs and washers used by the engine platform, which minimizes scatter in tightening results and supports consistent emissions and performance outcomes.

- · Performance: Stable clamp load supports combustion sealing and turbo efficiency.

- · Reliability: Proven metallurgy and locking features resist thermal and vibrational loosening.

- · Budget: Fewer unplanned stoppages and predictable overhaul cycles lower total cost.

- · Service life: Correct hardness and coatings reduce galling and corrosion, extending joint longevity.

- · Compliance: Documentation and traceability support class and audit requirements.

- · Fit: Thread class and collar geometry match engine design without rework.

Specifying a COLLAR NUT OEM parts set for a diesel engine ensures that torque-angle procedures, lubrication recommendations, and service intervals remain valid across fleet units, simplifying maintenance and inventory control.

MOPA as your partner for COLLAR NUT OEM parts and engine Nuts

MOPA is an experienced, reliable partner for OEM spare parts for Nuts across leading diesel and gas engine platforms. We focus on speed, quality, and security in the trade of OEM parts, supplying COLLAR NUT solutions for marine engine applications as well as comprehensive fastener kits for overhauls and retrofits.

Purchasers and technical decision-makers rely on MOPA for precise part-number matching, rapid availability from curated stock, and rigorous quality checks. Our team supports cross-references, documentation, and logistics so that critical fasteners arrive on time, verified, and ready for installation—reducing risk during tight docking windows or peak power demand.

Conclusion

Nuts—especially the COLLAR NUT—are fundamental to maintaining preload and structural integrity in marine, diesel, and gas engines. Selecting and replacing them with OEM spare parts suitable for Nuts safeguards performance, reliability, and lifecycle cost. Partner with MOPA to source COLLAR NUT OEM parts quickly and confidently for demanding engine environments.