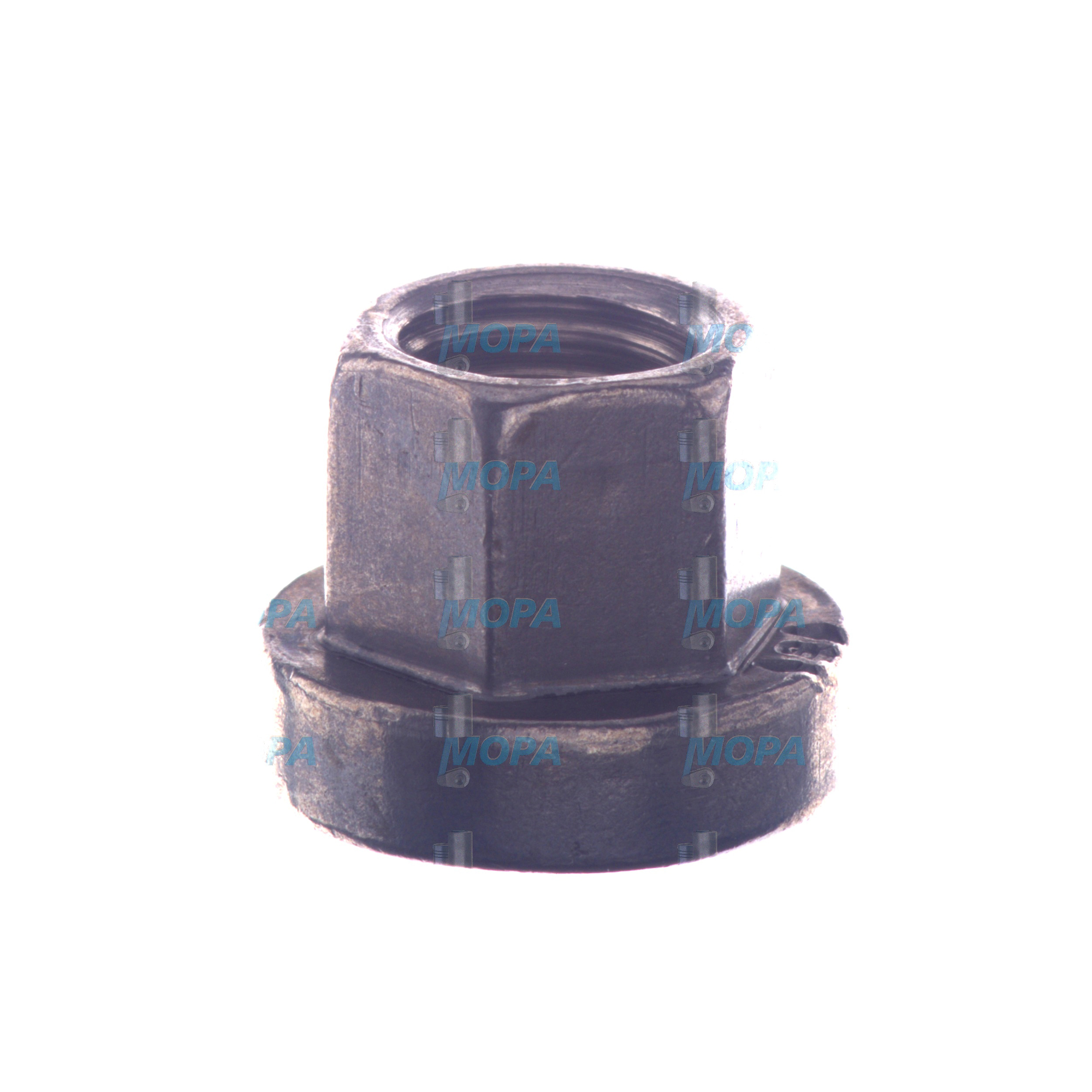

HEX COLLAR NUT – High-strength Nuts for Marine and Diesel Engines

Nuts are fundamental fasteners that secure bolts and studs across every part of an engine. In propulsion systems, gensets, and auxiliary drives, they maintain precise clamping loads that hold structural interfaces together—exhaust manifolds to cylinder heads, turbocharger brackets to housings, or engine mounts to bedplates. Within this category, the HEX COLLAR NUT (often called a hex flange nut) stands out for its integrated washer-like collar that spreads load and improves joint reliability. In high-vibration and high-temperature environments typical of marine engines and diesel engines, the right nut design directly impacts performance, safety, and service life.

Technical function: how Nuts with HEX COLLAR NUT design secure engine assemblies

A HEX COLLAR NUT combines a standard hex profile with a broad, machined flange. This collar distributes bearing stress over a larger surface, reducing localized embedment and maintaining bolt preload under thermal cycling. On engines, preload stability is crucial: it keeps gasketed joints sealed, prevents movement between parts, and resists fatigue in bolts and studs.

In a diesel engine or marine engine, dynamic loads and vibration tend to loosen conventional fasteners. A serrated HEX COLLAR NUT mechanically bites into the mating surface to create a prevailing torque effect that resists rotation. Even in non-serrated variants, the collar minimizes washer stack-ups, controls friction more predictably, and improves torque-to-tension correlation. For critical joints, technicians often tighten to a defined torque-angle to achieve repeatable stretch; collars help maintain this stretch by lowering the risk of joint relaxation.

Material and specification matter. High-strength steel nuts in property classes 8, 10, or 12 (per ISO 898-2) deliver the tensile capacity required for connecting rod caps, flywheel housings, and accessory drives. Standards such as DIN 6923 or ISO 4161 define the hex flange geometry, while ISO 2320 covers prevailing torque types. Protective finishes—zinc-nickel, phosphate with oil, or stainless grades—are selected to manage corrosion, friction coefficients, and temperature exposure. Correct thread class (e.g., 6H metric, UNC/UNF) ensures proper engagement length and clamp distribution. When sourcing HEX COLLAR NUT OEM parts, consistent metallurgy and coating friction factors (K-values) are essential for accurate tightening in service.

Key characteristics and advantages of Nuts in engine use:

· High and stable clamping force under vibration and heat

· Integrated collar distributes load and reduces need for separate washers

· Serrated options resist loosening in marine engine duty cycles

· Available in high-strength property classes for critical joints

· Coatings tailored for corrosion control and predictable friction

· Metric and inch threads for global fleets and mixed assets

· Compatible with torque-angle and yield tightening strategies

· Aligns with DIN/ISO specifications for dependable interchangeability

Importance for engine operation: why a HEX COLLAR NUT matters

When a nut loses preload, gaskets can leak, studs can bend, and interfaces can fret. On exhaust lines, this means hot-gas leakage and turbo inefficiency; on mounts, it can escalate to misalignment, vibration growth, and bearing damage. In a diesel engine, loosening at the manifold or turbocharger can raise backpressure, reduce power, and accelerate component fatigue. In a marine engine, salt-laden atmospheres intensify corrosion, which can reduce thread strength and friction consistency—further risking clamp loss.

Wear, galling, or surface damage on the collar undermines load distribution. Overheating can temper nut hardness and degrade prevailing torque. Poor coatings alter friction, causing under- or over-tightening at a given torque. Any of these issues compromise safety and increase lifecycle cost. Selecting the right HEX COLLAR NUT and maintaining replacement intervals protects alignment, sealing, and structural integrity across the engine.

Advantages of OEM spare parts suitable for Nuts and HEX COLLAR NUT applications

Using OEM spare parts suitable for Nuts ensures that the fastener matches the engine maker’s design assumptions—thread tolerance, hardness, heat treatment, and coating friction coefficients. This alignment translates into reliable torque-tension performance and consistent preload retention over time.

· Proven metallurgy and heat treatment for targeted strength

· Coating systems validated for temperature, corrosion, and friction

· Tight dimensional tolerances for repeatable fit with studs and bolts

· Documented traceability and testing for risk reduction

· Lower downtime through predictable torque procedures

· Better total cost of ownership via extended service intervals

· Compatibility with mating components and sealing systems

· Confidence in critical joints across diesel and gas engines

In short, OEM spare parts suitable for a HEX COLLAR NUT help protect performance, reliability, budget, and service life by preserving the engineered clamp design of each joint.

MOPA – the fast, reliable partner for OEM HEX COLLAR NUT and Nuts

MOPA supplies OEM parts for diesel and gas engines with a focus on speed, quality, and security. Whether you require a HEX COLLAR NUT for a marine engine exhaust manifold, a turbocharger bracket, or a baseframe mount, our sourcing network and technical expertise ensure that you receive the correct specification—property class, thread form, and coating—on time and with dependable documentation. We support purchasers, shipowners, and technical decision-makers with responsive quotations, vetted suppliers, and logistics that keep fleets and plants running.

Quality-first trade in OEM parts for marine and industrial power

From single replenishments to planned overhauls, MOPA helps standardize your fastener packages, reduce variability in torque outcomes, and minimize rework. Our team understands how a HEX COLLAR NUT in a diesel engine joint behaves under thermal cycling, and we match parts to those demands to safeguard uptime.

Conclusion: secure engine performance with the right HEX COLLAR NUT

Nuts—and especially the HEX COLLAR NUT—are small components that deliver large consequences for engine integrity, sealing, and alignment. Selecting OEM spare parts suitable for Nuts ensures consistent clamp loads and durability in harsh marine and industrial environments.

Partner with MOPA to source OEM HEX COLLAR NUT parts that align with your engine’s specifications and operating profile—fast, precise, and secure.