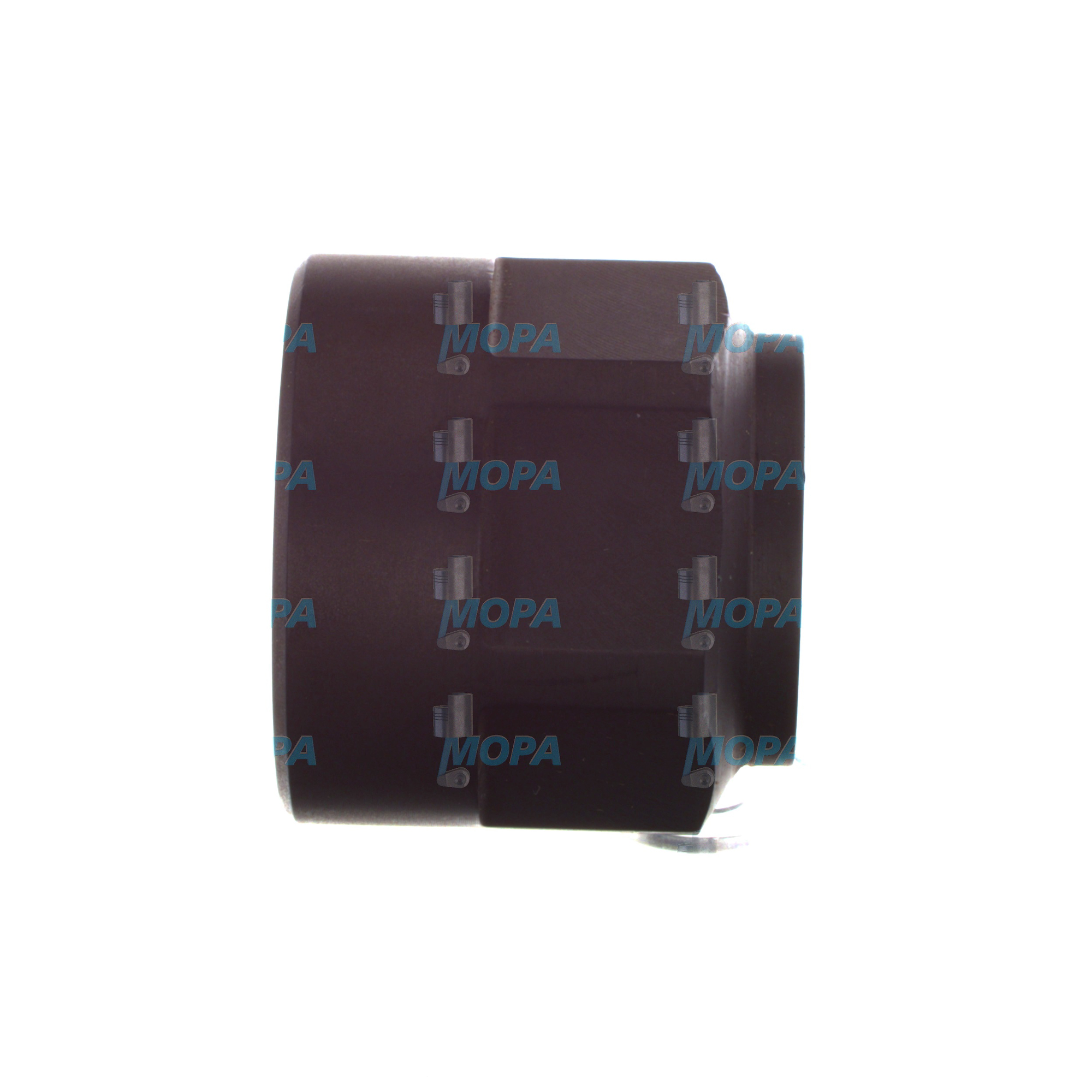

NOZZLE CAP NUT and high-precision Nuts for diesel and marine engines

Nuts are small, high-load fasteners that secure critical joints throughout an engine. From cylinder heads and main bearing caps to fuel equipment and exhaust systems, these components convert tightening torque into reliable clamping force that keeps parts aligned, sealed, and safe under extreme thermal and mechanical stress. In heavy-duty diesel and gas engines—especially in marine engine environments—nuts must maintain preload despite vibration, pressure pulsations, and repeated heat cycles. Within this category, the NOZZLE CAP NUT plays a particularly vital role by fastening and sealing the fuel injector nozzle assembly, ensuring accurate injection and clean combustion.

Technical function of Nuts and the NOZZLE CAP NUT in a diesel engine

The primary job of an engine nut is to create and hold a defined preload in a bolted joint. When correctly torqued (often with torque-angle methods), the nut stretches the stud or bolt just enough to act like a spring. That spring effect resists loosening, keeps gasket surfaces compressed, prevents micro-movement, and preserves precise component geometry. Engine builders select nut type, thread pitch, property class (e.g., 8, 10, 12), and material/coating to match the load, temperature, and corrosion profile of the application.

The NOZZLE CAP NUT in a diesel engine clamps the injector nozzle holder into the cylinder head and maintains a controlled seal around the injection point. It must withstand combustion chamber pressure spikes, fuel pressure, and thermal gradients without losing preload. Any loss of clamping may trigger injector “blow-by,” carbon tracks, leaking fuel, misfires, and elevated exhaust temperatures. In a marine engine, a NOZZLE CAP NUT also resists saline corrosion and long operating cycles, so surface treatments and base materials are chosen to reduce galling, pitting, and thread seizure. Specified NOZZLE CAP NUT OEM parts balance hardness, ductility, and coating friction factors (K values) so that torque translates into predictable clamping force.

Other engine nuts—such as cylinder head nuts, connecting rod nuts, turbocharger flange nuts, and exhaust manifold nuts—face different but equally severe conditions. Some use all‑metal prevailing torque features or serrated flanges to resist loosening; others rely on high-temperature alloys or phosphate coatings for consistent friction and retightening behavior. Proper fit (thread class and pitch), flatness of seating faces, and correct lubrication of threads and nut bearing surfaces are essential for accurate preload and long service intervals.

- · Maintains precise clamping force and joint integrity.

- · Resists vibration, thermal cycling, and pressure pulsations.

- · Supports sealing of fuel, oil, coolant, and exhaust interfaces.

- · Enables predictable torque-to-tension conversion.

- · Available in heat- and corrosion-resistant materials/coatings.

- · Critical for injector sealing: NOZZLE CAP NUT in diesel and marine engines.

Importance of Nuts for reliable engine operation and service life

Every rotating assembly, pressurized line, and hot-zone component in an engine depends on stable bolted joints. When nuts lose preload, the consequences escalate quickly: gaskets relax and leak, studs bend or break, mating faces fret, and rotating parts fall out of alignment. In the injector area, a degraded NOZZLE CAP NUT can cause fuel leaks, combustion blow-by, poor atomization, and rising SFOC due to incomplete burn. Over time, these faults lead to higher emissions, increased thermal stress on pistons and valves, and unplanned shutdowns.

In marine engine service, long duty cycles magnify these risks. Salt-laden air accelerates corrosion; temperature ramps during load changes amplify differential expansion; and constant vibration tests the joint’s resilience. Correctly specified nuts, tightened to the engine maker’s procedures, protect uptime, simplify maintenance planning, and extend component life. Routine inspection for discoloration, thread damage, or seating face wear—especially on the NOZZLE CAP NUT and other hot-side fasteners—helps detect early-stage issues before they cause costly repairs.

Advantages of OEM spare parts suitable for Nuts and NOZZLE CAP NUT OEM parts

When replacing fasteners, dimensional and metallurgical fidelity are non-negotiable. OEM spare parts suitable for Nuts are built to the exact thread tolerances, property classes, and heat treatments expected by the engine design, supporting repeatable torque/preload relationships and consistent sealing behavior. For a NOZZLE CAP NUT, this precision ensures the injector nozzle sits square, the sealing faces mate correctly, and torque values deliver the intended clamping force—critical for clean combustion and fuel efficiency.

Beyond fit and strength, OEM spare parts provide traceable material specs, proven coatings, and documented performance in the relevant temperature and corrosion spectrum. That translates into fewer retorque events, reduced risk of galling during removal, and stable friction coefficients across service intervals—protecting both performance and budget by lowering maintenance hours and preventing collateral damage to studs, seats, and housings.

- · Consistent preload and sealing at specified torque.

- · Verified materials, heat treatment, and coatings.

- · Lower risk of thread damage, galling, or seizure.

- · Stable performance under heat, vibration, and corrosion.

- · Predictable service life and optimized maintenance cycles.

- · Fit-for-purpose NOZZLE CAP NUT options for diesel and marine engines.

MOPA as a partner for OEM spare parts Nuts and NOZZLE CAP NUT

MOPA is an experienced and reliable partner for OEM spare parts suitable for Nuts, including the NOZZLE CAP NUT for diesel and gas engines. We focus on speed, quality, and security in the trade of OEM parts, helping purchasing teams and technical managers source precisely matched components with short lead times and full documentation. From injector fastening hardware to high-temperature manifold nuts, MOPA aligns procurement with maintenance schedules and class requirements, minimizing downtime and ensuring consistent engine performance.

Conclusion: Nuts and NOZZLE CAP NUT keep engines tight, efficient, and safe

Nuts are small but decisive components that safeguard alignment, sealing, and load paths throughout an engine. The NOZZLE CAP NUT, in particular, is central to injector sealing and combustion quality. Choosing OEM spare parts suitable for Nuts secures the intended preload, preserves efficiency, and protects budgets by reducing failures and extending service intervals.