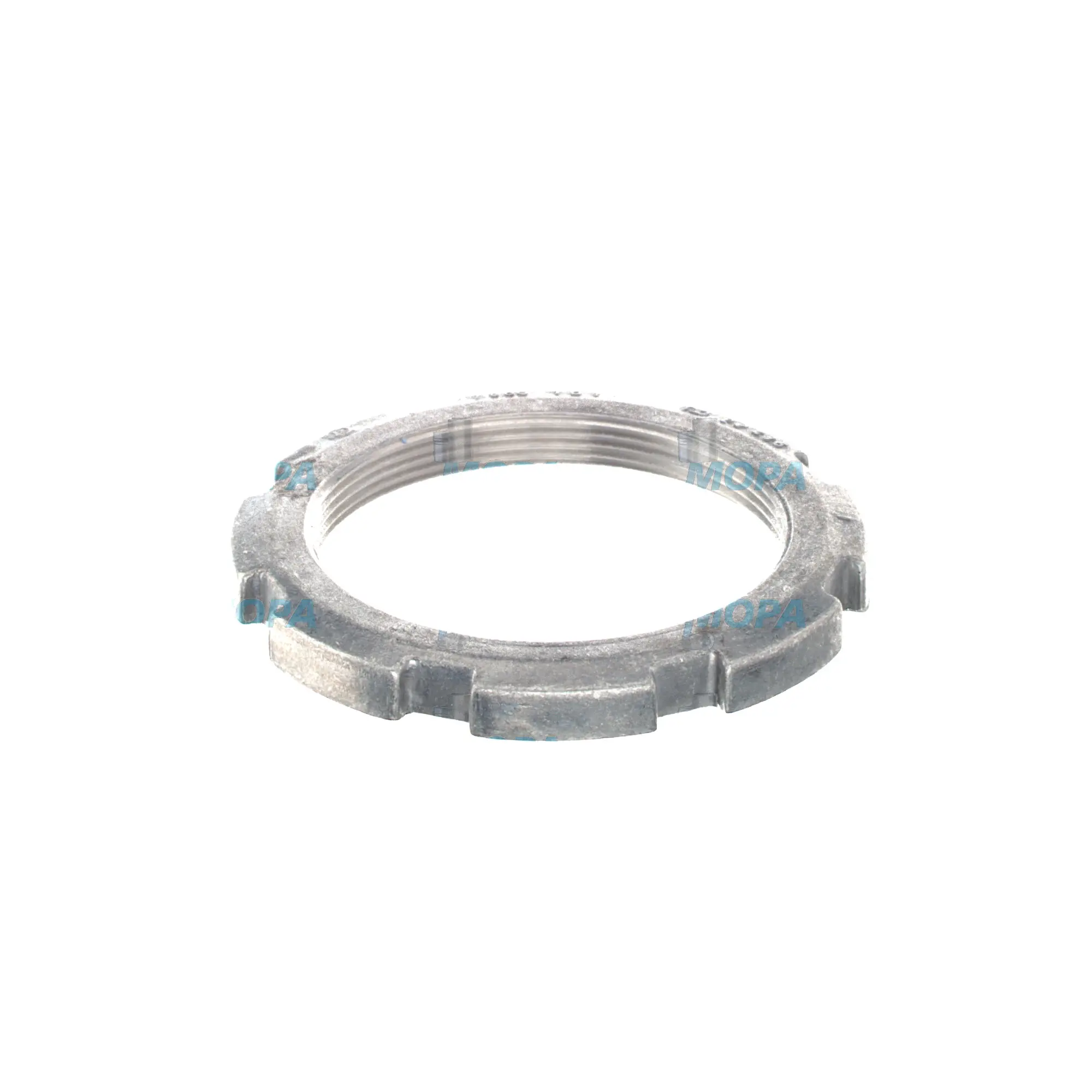

SLOTTED ROUND NUT for engine assemblies – high-performance Nuts that secure critical joints

Nuts are precision fastening components that clamp, lock, and align the most stressed interfaces in engines. From bearing housings and gear trains to couplings and exhaust systems, correctly specified Nuts preserve preload, resist vibration, and keep structural loads flowing through the intended paths. Within this category, the SLOTTED ROUND NUT is a key design for axial retention and fine adjustment on shafts and bearing seats—vital in heavy-duty diesel and gas engines as well as in marine engine environments where shock loads and corrosion are elevated.

Engine builders and operators depend on the dimensional accuracy, material strength, and surface treatments of Nuts to ensure torque retention over thousands of operating hours. When the right nut design is matched to the mating bolt or shaft thread—and correctly tightened and locked—the result is stable performance, predictable maintenance intervals, and measurable gains in availability.

Technical function of Nuts and the role of a SLOTTED ROUND NUT in diesel and marine engine assemblies

In an engine, Nuts deliver controlled clamping force by converting applied torque into bolt or shaft preload. This preload keeps joint members in compression, preventing micro-movement that leads to fretting, leaks, or misalignment. A SLOTTED ROUND NUT—commonly used with a tab washer or cotter arrangement—adds a positive locking feature for axial retention on threaded shafts. Typical applications include securing rolling bearings on crankshaft gear trains, setting bearing preload on camshaft carriers, fixing couplings on accessory drives, and locking thrust bearings on propulsion lines in marine engine installations.

Precision matters. The thread form (e.g., ISO metric, UNC/UNF), tolerance class (e.g., 6H/6g engagement), and face squareness of the nut influence how evenly load transfers into the joint. Materials range from high-tensile alloy steels for hot zones to stainless solutions for corrosion-exposed locations. Heat treatment controls hardness and tensile strength, while coatings—such as zinc flake or phosphate with dry-film lubricants—stabilize friction coefficients for consistent torque-to-tension behavior.

Compared to hex profiles, a SLOTTED ROUND NUT is designed for axial adjustment with hook or pin spanners and then locked using slots and a tab or pin. This makes it ideal where precise bearing endplay or preload must be set, especially in propulsion and auxiliary drives on a marine engine or a high-output diesel engine. In these assemblies, the SLOTTED ROUND NUT with OEM parts compatibility ensures reliable fit, correct slot alignment to the tab washer, and repeatable assembly torque.

- · High preload stability under vibration and thermal cycling

- · Positive locking via slots, tab washers, or cotter pins

- · Fine axial adjustment for bearing preload and gear mesh

- · Broad size range for shaft and bolt threads in engines

- · Material and coating options for heat and corrosion resistance

- · Tight dimensional tolerances for concentricity and face runout

- · Traceable production for maintenance and compliance records

Importance of Nuts for engine reliability and service life

Engine joints see cyclic tensile loads, bending, and high-frequency vibration. If Nuts lose preload or suffer thread damage, several failure modes follow: bearing preload drifts, leading to heat and early bearing fatigue; gear backlash increases, generating noise and wear; flange joints weep and then leak; and coupling misalignment accelerates shaft and seal damage. In the worst cases, a loose critical nut on a rotating assembly can result in sudden seizure or catastrophic disassembly.

Keeping Nuts within spec—right thread fit, correct hardness, and compatible friction characteristics—extends service life. Regular inspection for corrosion, galling, or plastic deformation, and renewing the SLOTTED ROUND NUT on shafts whenever locking features show wear, helps maintain stable torque retention. Using compatible locking elements (tab washers, locking plates) and following approved torque and angle procedures are essential for safe, repeatable outcomes.

Advantages of OEM spare parts suitable for Nuts and SLOTTED ROUND NUT

Choosing OEM spare parts suitable for the Nuts in your engine delivers tangible performance and cost benefits throughout the equipment lifecycle. These components are engineered to the same dimensional and metallurgical criteria as the parts the engine was designed around, ensuring predictable assembly behavior and long-term stability.

Why OEM spare parts matter for performance, reliability, budget, and service life

With OEM spare parts suitable for a SLOTTED ROUND NUT, you get controlled thread tolerances, verified material grades, and coatings calibrated for the specified torque-lubrication combination. That fidelity preserves preload, reduces re-torque events, and lowers the risk of thread galling or unwinding under vibration. For purchasers and fleet operators, this translates into optimized total cost of ownership by minimizing unplanned stops, simplifying audits with full documentation, and enabling consistent torque targets across vessels or sites.

- · Dimensional fidelity to maintain shaft/bearing geometry

- · Proven metallurgy and heat treatment for tensile strength

- · Coating systems matched to the joint’s friction coefficient

- · Slot geometry compatible with tab washers and spanners

- · Batch traceability for service and compliance records

- · Lower downtime through consistent fit and fast installation

MOPA – reliable partner for OEM spare parts Nuts and SLOTTED ROUND NUT

MOPA supplies OEM parts for diesel and gas engines with a clear focus on speed, quality, and security. Our network provides rapid availability of Nuts across critical sizes and standards, including the SLOTTED ROUND NUT variants used on bearing and coupling assemblies in marine engine applications. We source from audited manufacturers, perform incoming inspections, and deliver parts with the documentation you need for classification and maintenance records.

Purchasers and technical decision-makers benefit from responsive quotations, precise cross-referencing of part numbers, and shipping solutions that keep downtime to a minimum. Whether you operate coastal vessels, offshore assets, or power generation sets, MOPA streamlines the procurement of OEM spare parts for Nuts so you can restore engine availability quickly and confidently.

Conclusion: Nuts and SLOTTED ROUND NUT as a foundation for engine performance

Nuts are small components with outsized impact on engine integrity, and the SLOTTED ROUND NUT is indispensable wherever axial retention and fine adjustment are required. Selecting OEM spare parts suitable for Nuts safeguards preload, stabilizes performance, and extends service life while protecting budgets through fewer unplanned interventions.

Partner with MOPA to secure high-quality OEM parts for diesel and gas engines—delivered fast and documented for safe, reliable operation.