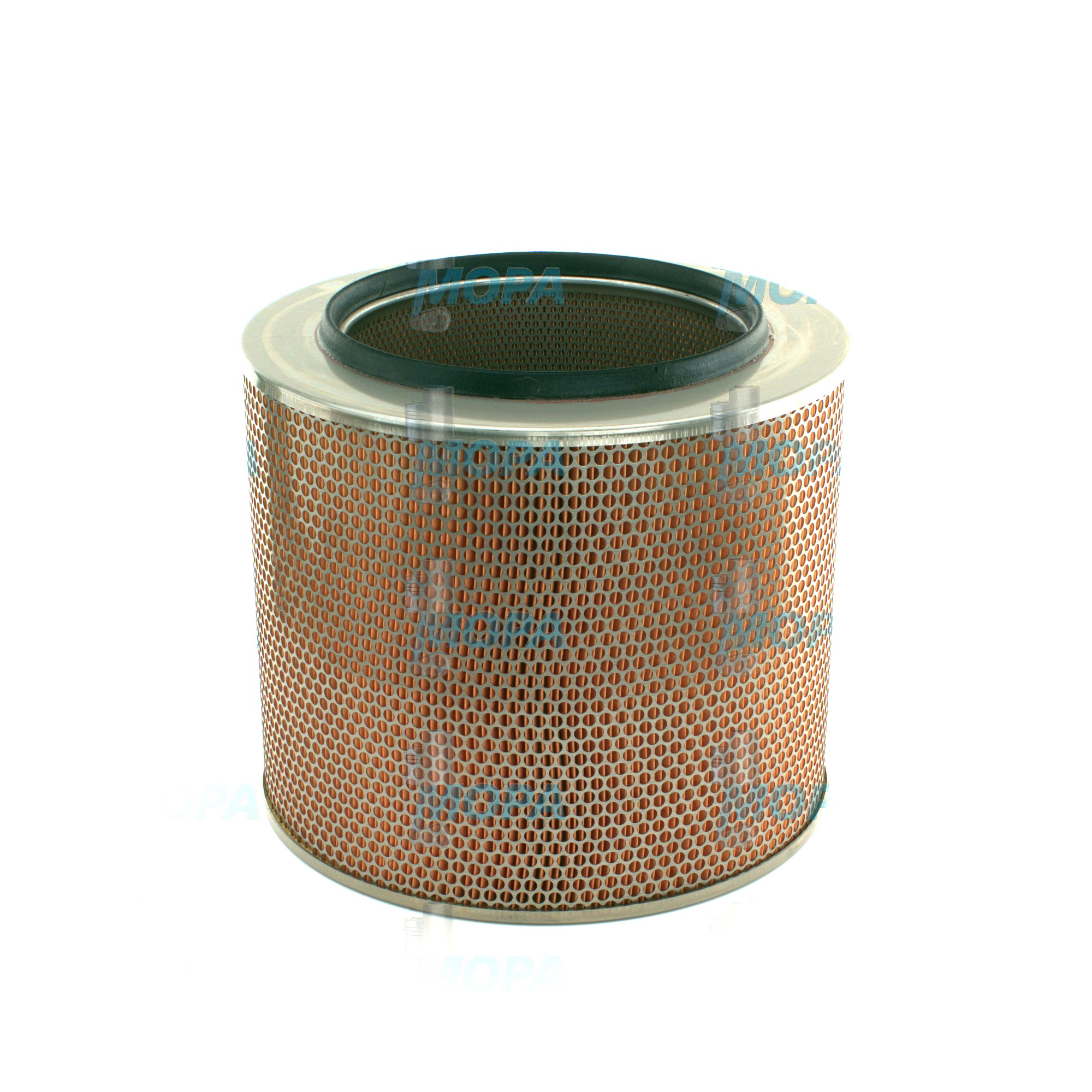

CARTRIDGE components in the Other category for marine and diesel engines

The “Other” article category brings together a wide range of specialized engine components that fall outside traditional groups like cylinder, fuel injection, or cooling systems—but are indispensable to safe, efficient operation. Typical items include filter CARTRIDGE elements for lube oil, fuel and coolant, turbocharger CHRA cartridges, sensors, valves, seals, and installation hardware. In heavy-duty diesel and gas engines—especially in marine engine applications—these parts ensure clean media, accurate measurement, stable pressures, and reliable air handling. Without them, even the best-maintained prime movers cannot sustain performance or uptime.

For purchasers and technical managers, this “Other” portfolio is central to preventive maintenance and overhaul planning. Filter and turbo CARTRIDGE replacements, condition sensors, safety valves, and ancillary kits are scheduled by running hours, differential pressure, or OEM specifications to protect major assets. The result is predictable service life, stable emissions, and reduced lifecycle cost across fleets and power plants.

CARTRIDGE technical function and the role of Other components

Within the “Other” category, CARTRIDGE solutions perform two high-impact functions: filtration and turbocharging. In a diesel engine, lube oil and fuel filter cartridges trap particulates and water to ISO cleanliness targets, using pleated cellulose, microglass, or synthetic media. Their performance is defined by micron rating, Beta ratio (per ISO 16889), collapse strength, dirt-holding capacity, and pressure-drop characteristics. A well-matched oil filter CARTRIDGE marine engine set keeps bearings in hydrodynamic lubrication, stabilizes viscosity, and prevents abrasive wear. Fuel filter cartridges protect injectors and pumps from scoring, while water-separating elements safeguard precision injection systems against corrosion and poor spray patterns.

In forced-induction systems, the turbocharger CHRA—commonly called a turbo CARTRIDGE diesel engine assembly—houses the turbine wheel, compressor wheel, shaft, and bearing system. Correct clearances and oil-film stability inside the cartridge govern boost pressure, surge margin, and thermal behavior. High-speed balancing of the CARTRIDGE OEM parts CHRA reduces vibration, increases turbo efficiency, and protects the engine from overspeed events. When matched to engine load profiles, a healthy cartridge improves specific fuel consumption and transient response, directly influencing vessel maneuverability and part-load emissions.

Beyond these, the “Other” category includes pressure-control valves, thermostats, level and temperature sensors, gaskets, and fasteners—components that maintain setpoints, seal systems, and relay accurate data to the control unit. Together with CARTRIDGE elements, they form the enabling layer that keeps core engine systems within design limits.

- · Broad scope: filtration, turbo CHRA, sensors, valves, seals.

- · Performance impact: cleaner fluids and stable boost improve efficiency.

- · Safety contribution: correct pressures and temperatures prevent failures.

- · Service-friendly: modular CARTRIDGE designs speed replacement.

- · Compliance support: consistent readings and filtration aid emissions control.

- · Lifecycle value: reduced wear extends overhaul intervals.

Importance of the Other category for engine reliability and service life

Neglecting items in the “Other” category quickly drives up operational risk. Clogged oil filter cartridges elevate differential pressure, trigger bypass valves, and circulate unfiltered oil—accelerating bearing and cam wear. Saturated fuel cartridges allow particulates and water to reach injectors, causing poor atomization, tip erosion, and increased smoke. A worn turbo CARTRIDGE can lose balance, increase heat load, and reduce compressor efficiency; in severe cases, it risks shaft failure and unplanned off-hire. Faulty sensors or sticking thermostats push engines outside safe temperature or pressure bands, compounding wear and compromising class compliance.

In marine engine duty—long hours, variable loads, contaminated bunkers—the cumulative effect is stark: higher fuel burn, rising lube consumption, and more frequent corrective maintenance. Keeping these “Other” parts, especially the filtration and turbo CARTRIDGE elements, in top condition is essential to preserving reliability, protecting major components, and meeting planned TBO targets.

Advantages of OEM spare parts suitable for Other CARTRIDGE solutions

Choosing OEM spare parts suitable for the “Other” category ensures each CARTRIDGE and ancillary component meets the design intent of the engine and auxiliary systems. Filtration elements are validated to deliver the specified Beta ratios and dirt-holding capacity at the correct pressure drop, maintaining oil film integrity and injection cleanliness. Turbo CHRA CARTRIDGE OEM parts receive application-specific balancing and material controls, ensuring dimensional accuracy, thermal stability, and bearing life that generic substitutes cannot replicate. Sealing elements use approved elastomers and profiles to prevent microleaks that degrade lubrication and cooling circuits.

This fidelity to the engine’s specification pays back in measurable ways: stable fuel economy, lower wear metals in oil analysis, fewer alarm events, and predictable service intervals. Over a maintenance cycle, OEM spare parts suitable for the “Other” category reduce the risk of collateral damage—such as turbo failure following a poor-quality oil filter—or compliance issues tied to inconsistent sensor output. For purchasing teams, the result is improved budget stability and optimized total cost of ownership without compromising performance or safety.

MOPA as a partner for OEM spare parts in the Other category

MOPA supplies OEM spare parts for the complete “Other” range—filter and turbo CARTRIDGE assemblies, sensors, valves, seals, and associated kits—for diesel and gas engines across marine and stationary applications. Customers value MOPA’s speed of delivery, consistent quality, and transactional security, backed by precise part identification and documentation. Whether you need a lube oil filter CARTRIDGE marine engine set, a high-speed balanced turbo CARTRIDGE diesel engine CHRA, or instrumentation components, MOPA streamlines sourcing and minimizes downtime.

CARTRIDGE sourcing with MOPA: fast, accurate, secure

From cross-referencing part numbers to assembling overhaul kits, MOPA reduces lead times and errors. The team supports planned maintenance windows with on-time supply, batch traceability, and technical clarity—so your engines return to service quickly and confidently with the right CARTRIDGE and complementary “Other” components.

Conclusion: the value of the Other category and CARTRIDGE parts

The “Other” category may be diverse, but its impact is direct: clean fluids, stable boost, accurate sensing, and reliable sealing. Keeping CARTRIDGE elements and related parts to specification safeguards performance, extends service life, and supports compliance.

With OEM spare parts suitable for the “Other” category and a partner like MOPA, operators secure consistent engine behavior, predictable maintenance costs, and dependable uptime across fleets and power installations.