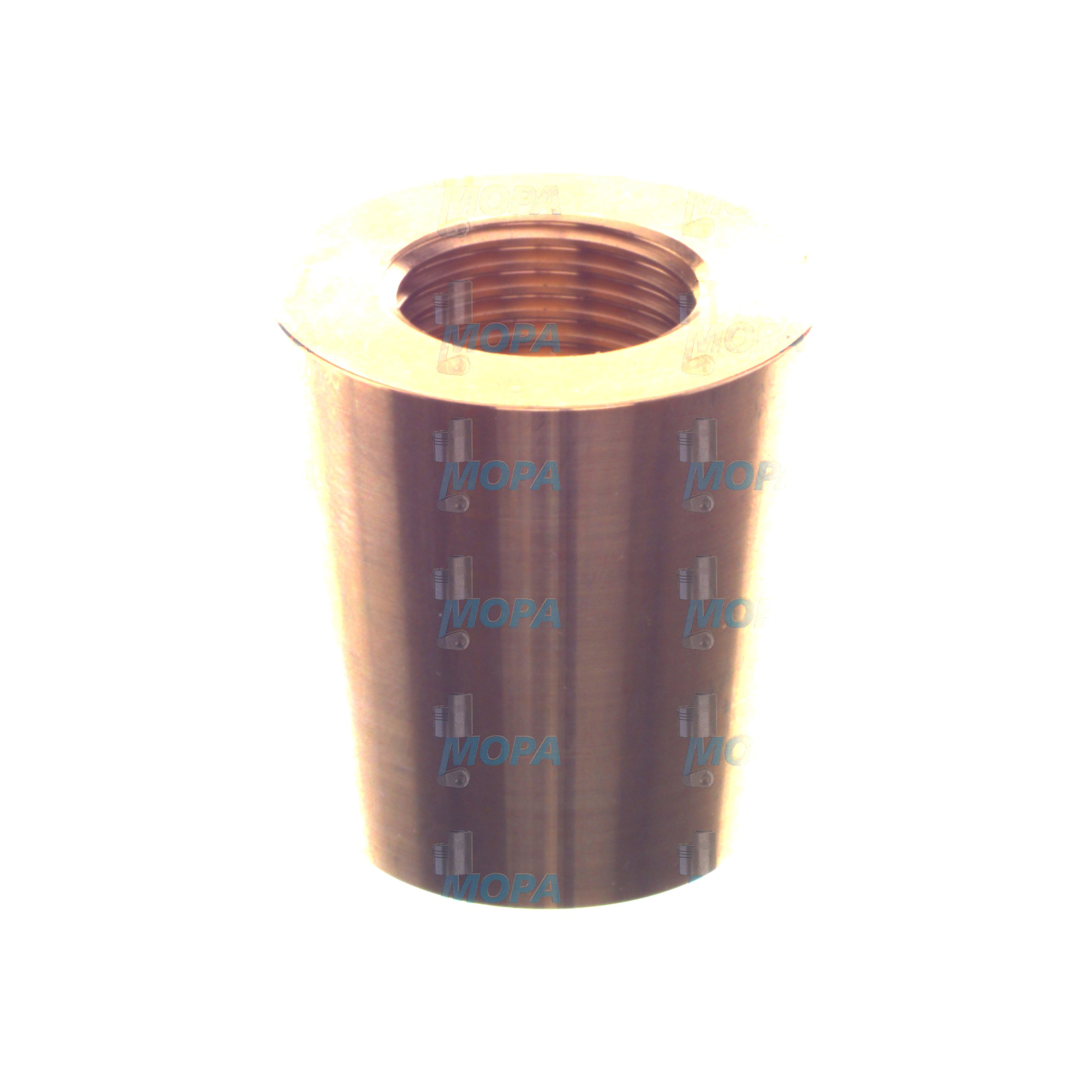

COMPRESSION GLAND – Other Engine Components for Marine and Diesel Applications

In the article category “Other,” purchasers and superintendents will find the diverse yet critical components that keep marine and diesel engines running safely and efficiently. These items often sit outside the headline assemblies, but they are indispensable for sealing, routing, fastening, and protecting vital flows and signals. A standout example is the COMPRESSION GLAND, a compact assembly that creates a reliable seal around a tube, rod, or cable to prevent leaks, maintain pressure, and block contaminants. In harsh engine-room conditions with vibration, heat, and salt-laden air, such “Other” components do the quiet, continuous work of safeguarding performance and uptime.

Whether used on fuel and lube oil lines, coolant and air circuits, or as cable glands for instrumentation and control wiring, a properly specified COMPRESSION GLAND helps the engine maintain consistent operating parameters. In a marine engine, it prevents fluid loss and ingress that could trigger alarms or shutdowns; in a diesel engine for power generation, it preserves pressure integrity to ensure stable combustion and accurate monitoring. This category consolidates these specialized, high-utility items so technical buyers can source precisely what they need—quickly and with confidence.

Technical function: how a COMPRESSION GLAND works in a diesel engine or marine engine

A COMPRESSION GLAND is engineered to create a tight, repeatable seal by compressing a ferrule or packing element between a gland body and a tightening nut. As the nut is torqued, radial compression forces the ferrule to grip the tube, rod, or cable jacket while simultaneously pressing against the body to form a metal-to-metal or elastomer-assisted seal. In fluid systems, this prevents leakage of fuel, oil, coolant, or compressed air. In electrical applications, a cable COMPRESSION GLAND provides strain relief and ingress protection, blocking moisture and dust while maintaining required bend radius and shielding continuity where applicable.

In a diesel engine’s high-vibration environment, the gland’s geometry and metallurgy are decisive. Materials such as stainless steel or nickel-plated brass resist corrosion; precision threads and surface finishes provide stable torque-to-tension characteristics; and correctly matched ferrule materials prevent galling and cold flow. For marine engine service, the gland must endure thermal cycling, pulsating pressures, and occasional shock loads without losing preload. When sourced as COMPRESSION GLAND OEM parts, dimensional fidelity across threads (NPT, BSPP, metric), taper angles, and sealing faces ensures consistent assembly results and reduces the risk of micro-leaks under dynamic loads.

For cable entries on engine-mounted junction boxes, ATEX/IECEx-compliant cable COMPRESSION GLAND designs help maintain enclosure ratings (e.g., IP66/68) and minimize the risk of water ingress that could compromise sensors, solenoids, or safety relays. Proper sizing relative to outer diameter and jacket compound is essential to achieve the intended compression without damaging conductors.

- · Robust sealing under vibration and thermal cycling

- · Precise fit across thread forms and tube/cable sizes

- · Corrosion-resistant materials for marine conditions

- · Stable torque and repeatable assembly

- · Protection against leaks, ingress, and pressure loss

- · Compatible with diesel, lube oil, coolant, and air systems

- · Supports safe routing of cables and instrumentation

- · Enables efficient maintenance and rapid replacement

Importance for engine operation: why “Other” parts like a COMPRESSION GLAND matter

The reliability of large engines is only as strong as their weakest sealing or connection point. A worn or poorly installed COMPRESSION GLAND can result in fuel mist, lube oil drips, or air leaks—each with different but serious consequences. Fuel leakage raises fire risk and can skew injection balance; oil leakage accelerates contamination and component wear; air leakage undermines pneumatic actuation and can distort sensor readings. In cable applications, a compromised gland allows moisture ingress, leading to intermittent faults, corrosion of terminals, and unexpected trips or deratings.

Over time, vibration can loosen under-torqued compression nuts; thermal cycling can relax seal stress; and incompatible materials can embrittle or swell, especially with biofuel blends or aggressive coolants. Routine inspections should check for witness marks, correct nut position, and signs of weepage. Replacing suspect glands before they escalate into downtime is a low-cost action with a high impact on availability, safety, and compliance.

Advantages of OEM spare parts suitable for Other and COMPRESSION GLAND

Choosing OEM spare parts suitable for Other components—especially a COMPRESSION GLAND—protects performance, budget, and service life in several ways. Tight tolerance control ensures the ferrule bites and seals exactly as designed, minimizing rework and re-tightening. Metallurgy traced back to controlled melts provides predictable corrosion resistance and mechanical properties, which is critical in marine atmospheres and on heat-soaked engine casings. Elastomeric elements are matched to media and temperature profiles, reducing hardening, swelling, or compression set.

Because OEM parts are validated against the engine builder’s specifications, technicians benefit from consistent assembly torque guidance and thread compatibility across platforms. This reduces install time and the risk of damaging mating components. Over the full lifecycle, fewer leaks, fewer call-backs, and stable sealing loads mean lower total cost and higher fleet availability—key metrics for shipowners and power plant operators.

Selecting COMPRESSION GLAND OEM parts for marine engine and diesel engine fleets

When specifying COMPRESSION GLAND OEM parts, align material and design with application: stainless steel or duplex for saline exposure; high-temperature seals near turbochargers; conductive cable glands for EMC continuity on sensor lines; and certified designs where hazardous-area rules apply. Confirm tube or cable OD ranges, thread standards, and pressure or ingress ratings to match the engine layout and class requirements.

MOPA as a partner for OEM parts: COMPRESSION GLAND and Other spares

MOPA is an experienced, reliable partner for OEM spare parts in the “Other” category, including COMPRESSION GLAND solutions for diesel and gas engines. We focus on speed—rapid quotation and dispatch to keep downtime to a minimum. We focus on quality—traceable sourcing and rigorous checks to align with engine-maker specifications. And we focus on security—transparent order handling, careful packing, and dependable logistics that protect your schedule and your equipment.

Whether you need a single COMPRESSION GLAND for a marine engine refit or a consolidated kit of Other components for a planned outage, MOPA streamlines procurement and minimizes risk across your supply chain.

Conclusion: COMPRESSION GLAND and Other components in focus

Small parts make a big difference. In the “Other” category, the COMPRESSION GLAND is a prime example of a compact component that protects pressure integrity, safety, and uptime in marine and diesel engines. Selecting OEM spare parts suitable for Other ensures consistent fit, reliable sealing, and long service life—benefits that translate directly into performance and cost control for your operation.