FLYWEIGHT Other Engine Components for Diesel and Marine Applications

The article category “Other” brings together specialized auxiliary components that do not fall into the major system groups but are vital for safe, efficient engine operation. These parts include mechanisms for speed control, sealing, alignment, protection, and mounting — the small but decisive elements that keep large diesel and gas engines on-spec. A prominent example in this category is the centrifugal governor FLYWEIGHT, a precision part that translates rotational speed into a control force. In marine engine and power generation settings, such “Other” components determine how reliably an engine starts, stabilizes, adapts to load changes, and avoids harmful operating states.

For purchasers and shipowners, the “Other” category offers the critical links between major assemblies: pins and springs that connect fuel racks, shims that define gear backlash, bushings that absorb vibration, seals that retain lubrication, and speed-control parts such as the FLYWEIGHT that enable consistent, repeatable performance. When these items meet the correct specifications, engines maintain output, emissions remain predictable, and maintenance windows stay under control.

Technical function of “Other” components with FLYWEIGHT in diesel engine control

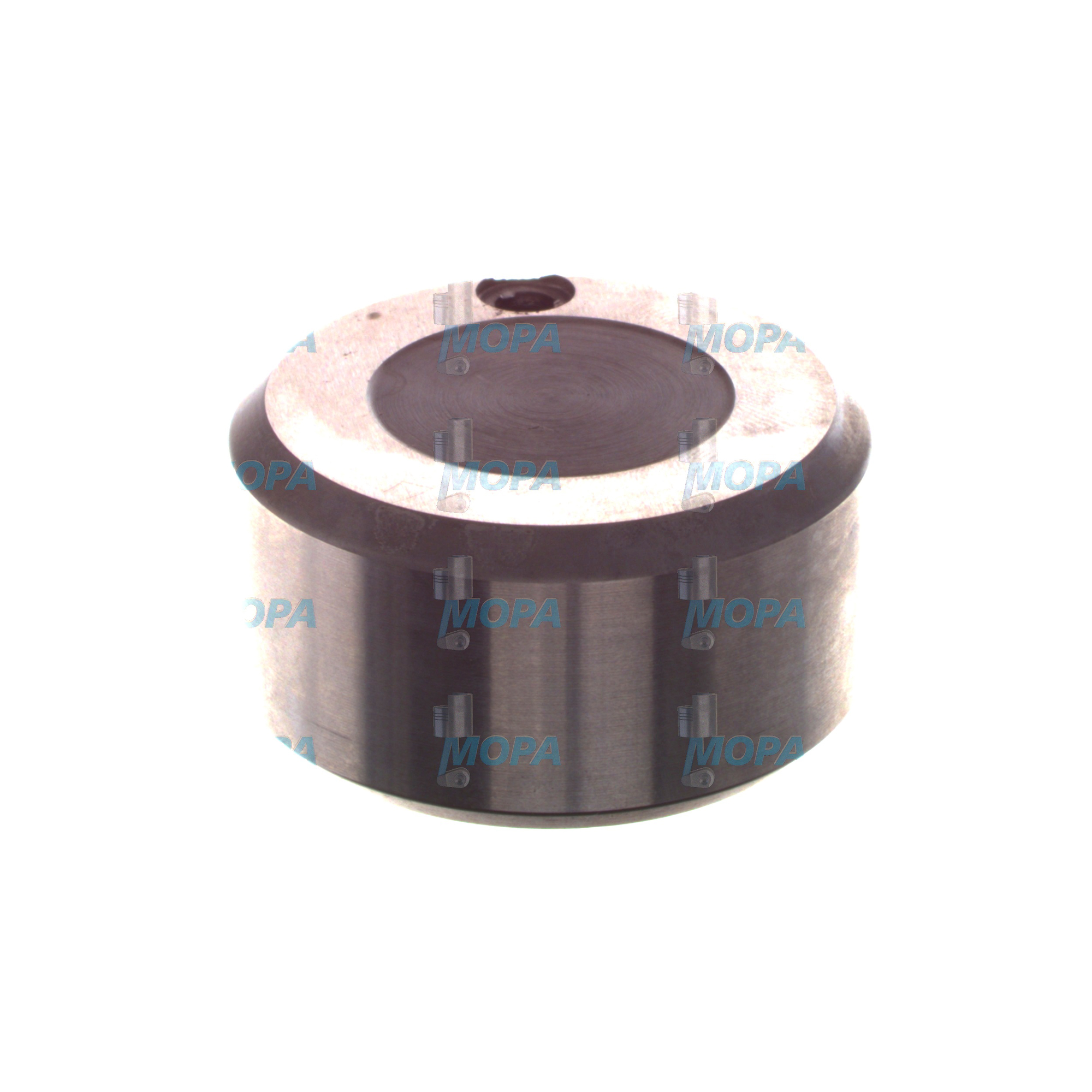

Within the “Other” group, the FLYWEIGHT often serves as the heart of a mechanical or hydromechanical governor. As the engine rotates, each flyweight pivots outward under centrifugal force proportional to shaft speed. Through a collar and lever, this motion opposes a calibrated spring, generating a net control signal that adjusts fuel delivery. In a diesel engine governor, the result is a stable setpoint: when speed rises, the FLYWEIGHT increases outward force, reducing fuel; when speed falls, the spring overcomes the reduced centrifugal force, adding fuel. Properly engineered, this control loop minimizes hunting, supports isochronous or droop characteristics, and maintains load acceptance without overshoot.

In a marine engine, the FLYWEIGHT can integrate with hydraulic amplifiers to modulate a servo piston, converting small mechanical displacement into precise rack movement. The geometry, mass, and surface finish of the FLYWEIGHT and its pivot pins directly affect response time, stability, and wear. Materials are chosen for fatigue resistance and dimensional stability, while heat treatment ensures the contact surfaces resist brinelling and fretting. Together with associated “Other” items — return springs, link rods, detents, shims, bushings, and seals — the assembly provides dependable speed control across the vessel’s operating profile, from maneuvering to full load.

How a FLYWEIGHT stabilizes a marine engine

Under varying propeller loads, a FLYWEIGHT marine engine governor senses speed deviation instantly. The flyweight pair produces a force balanced against a governor spring. The resulting collar displacement drives a pilot valve, which ports oil to a power piston; this piston moves the fuel rack to correct speed. Damping orifices and lever ratios are selected to prevent oscillation, and the mass distribution of the FLYWEIGHT determines the gain and bandwidth of the control loop. Any dimensional error in the flyweight, pins, or seats can introduce backlash and delay, causing speed hunting or slow load acceptance.

Key characteristics and advantages of the “Other” category

· Precise speed sensing via FLYWEIGHT assemblies in governors.

· Stable fuel control under transient loads and sea states.

· Wear-resistant pins, bushes, and seats that preserve geometry.

· Seals and gaskets that maintain oil pressure and cleanliness.

· Shims and spacers that set accurate clearances and backlash.

· Corrosion-resistant materials suited to marine environments.

· Tight tolerances that reduce vibration and noise.

· Traceable, spec-compliant fit for critical interfaces.

· Extended service intervals through correct material pairing.

· Proven compatibility with diesel and gas engine platforms.

Why “Other” components are critical for reliability and service life

Even minor deviations in these auxiliary parts can cause major issues. Worn FLYWEIGHT pins create lost motion, leading to speed instability, hunting, or erratic idle. Fatigued governor springs shift the control point, risking overspeed or sluggish load pickup. Poor-quality bushings accelerate shaft wear; incorrect shims lead to gear noise and pitting; hardened seals can leak, lowering oil pressure and increasing contamination. Over time, such faults elevate fuel consumption, raise exhaust temperatures, and shorten component life across the engine. Routine inspections often reveal that small “Other” components dictate whether an overhaul meets its expected runtime or requires unplanned intervention.

Advantages of OEM spare parts suitable for “Other” components and FLYWEIGHT

For governor FLYWEIGHT sets and the broader “Other” category, OEM spare parts deliver the exact geometry, mass, and hardness required by the engine platform. Correct mass matching ensures uniform centrifugal response between paired flyweights; specified spring rates maintain designed control curves; surface finishes reduce friction and micro-welding at pivot points. In sealing and mounting items, OEM parts preserve tolerance stacks so shafts, covers, and housings align as intended, maintaining oil distribution and shaft concentricity.

Beyond fit, OEM spare parts support performance and lifecycle economics. Consistent metallurgy and heat treatment sustain fatigue strength, minimizing downtime from premature wear. Supply-chain documentation and part numbering simplify audits and class approvals in maritime contexts. For operators, this translates into predictable maintenance windows, stable fuel efficiency, safer speed control, and reduced risk during load changes or black-start scenarios.

· Exact mass and balance for FLYWEIGHT diesel engine governors.

· Verified spring rates and lever geometries for stable control.

· Material specs that withstand thermal cycling and corrosion.

· Dimensional accuracy that protects shafts, gears, and seals.

· Repeatable performance that supports budget planning and uptime.

MOPA: your partner for OEM spare parts in “Other” components and FLYWEIGHT

MOPA supplies OEM parts across the “Other” category — from governor FLYWEIGHT kits to pins, springs, seals, and alignment hardware — with a focus on speed, quality, and security in the trade of OEM parts for diesel and gas engines. Our team understands the control dynamics of marine engine governors and the tolerance chains that tie small components to big outcomes. We provide fast quotations, reliable lead times, and consolidated shipments that reduce administrative effort and vessel downtime.

FLYWEIGHT OEM parts for marine engine governors

When sourcing FLYWEIGHT OEM parts, MOPA helps match part numbers to engine models, governor series, and revision levels, ensuring that mass, pin size, and spring pairing conform to the intended control law. We can kit associated “Other” items — collars, thrust washers, return springs, seals — so overhaul teams receive a complete, ready-to-install package that speeds turnaround and reduces risk of mismatch.

Conclusion on FLYWEIGHT and “Other” engine parts

The “Other” category, anchored by precise components like the FLYWEIGHT, plays a decisive role in how diesel and marine engines start, stabilize, and carry load. Selecting OEM spare parts suitable for this category preserves control accuracy, safeguards reliability, and optimizes lifecycle cost. With MOPA as a partner, operators secure the technical integrity and timely availability needed to keep fleets running efficiently and safely.