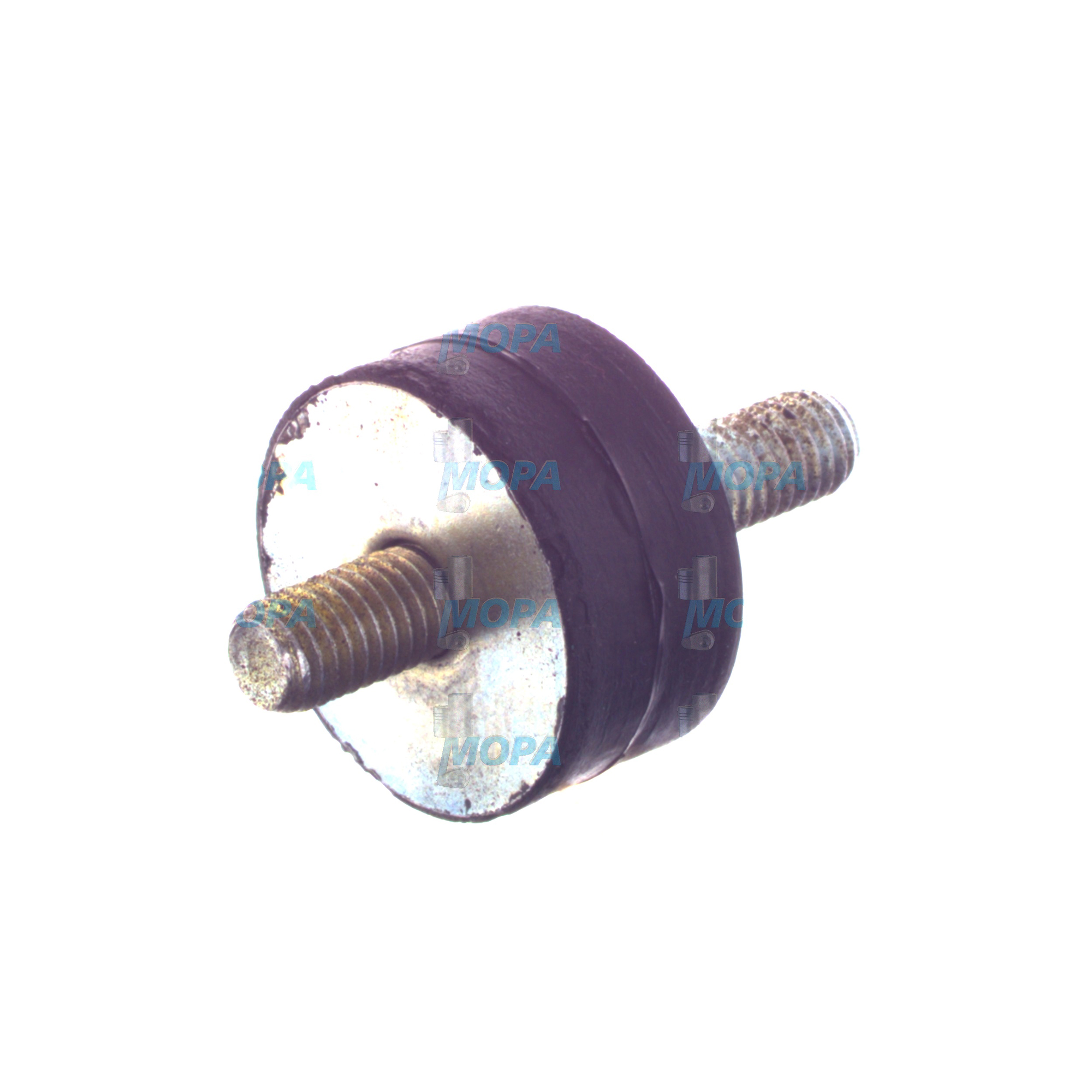

INSULATOR solutions for the Other category in marine and diesel engines

The article category “Other” groups together highly specialized components that sit outside the classic assemblies but are indispensable for safe, efficient engine operation. Within this category, the INSULATOR stands out as a key element for electrical isolation, thermal management, and component protection across diesel and gas engine platforms. From sensor standoffs and terminal boots to ceramic bushings and heat-resistant sleeves, these parts protect sensitive circuits, maintain signal integrity, and shield nearby hardware from excessive heat and vibration.

Shipowners, fleet managers, and industrial operators rely on “Other” components to close the gap between major systems and real-world operating demands. A correctly specified INSULATOR minimizes electrical leakage and arc-over, prevents heat soak in adjacent parts, and preserves clearances and creepage distances mandated by class rules and OEM documentation. In short, this category may be labeled “Other,” but its contribution to uptime, safety, and lifecycle cost is central to every marine engine and stationary diesel engine installation.

Technical function of INSULATOR parts in diesel engine and marine engine applications

An INSULATOR is designed to block electrical current flow where it is not intended and to reduce heat transfer from high-temperature sources. In a marine engine, typical INSULATOR parts include ignition lead separators for gas engines, alternator post boots, terminal caps for starting systems, and ceramic or polymer sleeves for sensor harnesses routed near exhaust components. In a diesel engine, injector spacer washers, exhaust-manifold barrier pads, turbo heat-shield underlayers, and ECU mounting isolators keep heat and stray currents under strict control. These components preserve the performance envelope by protecting electronics from thermal drift, preventing arc-tracking, and maintaining consistent readings from speed, pressure, and temperature sensors.

INSULATOR OEM parts are engineered with exact dielectric strength, comparative tracking index, thermal conductivity, and compression behavior to match the engine builder’s specification. Materials range from high-alumina ceramics and mica laminates to PTFE, PEEK, G10/FR4, and silicone-aramid composites. In practice, they maintain creepage and clearance distances under vibration, salt fog, and oil exposure; they also resist carbon tracking in humid, salty environments common to marine engine rooms. The result is stable performance, less electrical noise, and reduced risk of heat-induced degradation of nearby hoses, looms, and seals.

· Electrical isolation under high voltage and high humidity.

· Thermal shielding near turbochargers and exhausts.

· Stable sensor signals through reduced EMI and heat soak.

· Materials tuned for temperature, salt, oil, and vibration.

· Precise dimensions for correct creepage and clearance.

· Long service intervals thanks to proven durability.

· Compliance support for marine class and safety standards.

· Reduced downtime via predictable replacement cycles.

Why the “Other” category is crucial for reliable engine operation

Components in the “Other” category protect the engine’s supporting systems that often determine day-to-day reliability. If an INSULATOR hardens, cracks, carbon-tracks, or loses dimensional stability, the consequences can be severe: short circuits on alternator terminals, intermittent ECU faults, injector control issues, and unpredictable sensor readings. Thermal migration from a hot manifold into a wiring loom can embrittle insulation, cause chafing failures, or trigger nuisance alarms. In gas engines, degraded high-voltage insulators can increase misfire rates; in marine diesel engine rooms, compromised thermal barriers can accelerate aging of elastomers and increase the risk of localized overheating.

Maintaining robust insulation and thermal separation reduces unplanned stops, protects downstream components, and stabilizes fuel efficiency by keeping engine management systems within their designed operating windows. Ultimately, the humble INSULATOR underpins dependable starts, clean signals, and safe temperatures—cornerstones of asset availability and longer service life.

Advantages of OEM spare parts suitable for the “Other” category

Selecting OEM spare parts suitable for the “Other” category ensures that INSULATOR components match the engine’s precise material and dimensional specifications. That translates into consistent dielectric performance, correct torque compression under fasteners, and proven resistance to oils, fuel vapors, and salt-laden air. These parts are validated for the exact temperature gradients and vibration spectra around your installation, helping maintain performance and reliability while protecting budget over the full lifecycle.

With OEM spare parts, you secure documented traceability, repeatable quality, and interfaces that fit the OEM brackets, covers, and harness clips without rework. The net effect is faster turnaround during maintenance, less risk of re-failures, and stable performance metrics across fleets—especially relevant for operators balancing compliance, fuel optimization, and predictable OPEX.

How to select the right INSULATOR OEM parts

Match the material to the duty: ceramics and mica for high-radiant-heat locations; PTFE or PEEK for chemical and temperature stability; G10/FR4 for structural electrical isolation; silicone-aramid laminates for flexible thermal sleeves. Verify dielectric strength, CTI, UL 94 flammability class, and thermal conductivity against the engine manual. For marine engine use, consider salt fog resistance and marine approvals. For diesel engine applications, check long-term compression set and heat-aging in the vicinity of exhaust aftertreatment. Always align part codes with the engine’s BOM to secure the intended clearances and creepage distances.

MOPA as a partner for INSULATOR and “Other” OEM parts

MOPA is an experienced, reliable partner for OEM spare parts in the “Other” category, including every critical INSULATOR used around diesel and gas engines. We prioritize speed with responsive sourcing and short lead times, quality through rigorous supplier selection and documentation, and security in the trade of OEM parts to safeguard your supply chain. Whether for a single marine engine or a multi-site power portfolio, MOPA supports consistent specifications, clear traceability, and dependable logistics so maintenance windows stay tight and predictable.

Conclusion: INSULATOR excellence in the “Other” category

The “Other” category brings together small yet mission-critical elements that protect the electrical and thermal integrity of engines. High-quality INSULATOR components keep marine and diesel engines reliable, efficient, and safe under demanding conditions. By choosing OEM spare parts suitable for the “Other” category, operators secure consistent performance, extended service life, and cost control across the fleet.