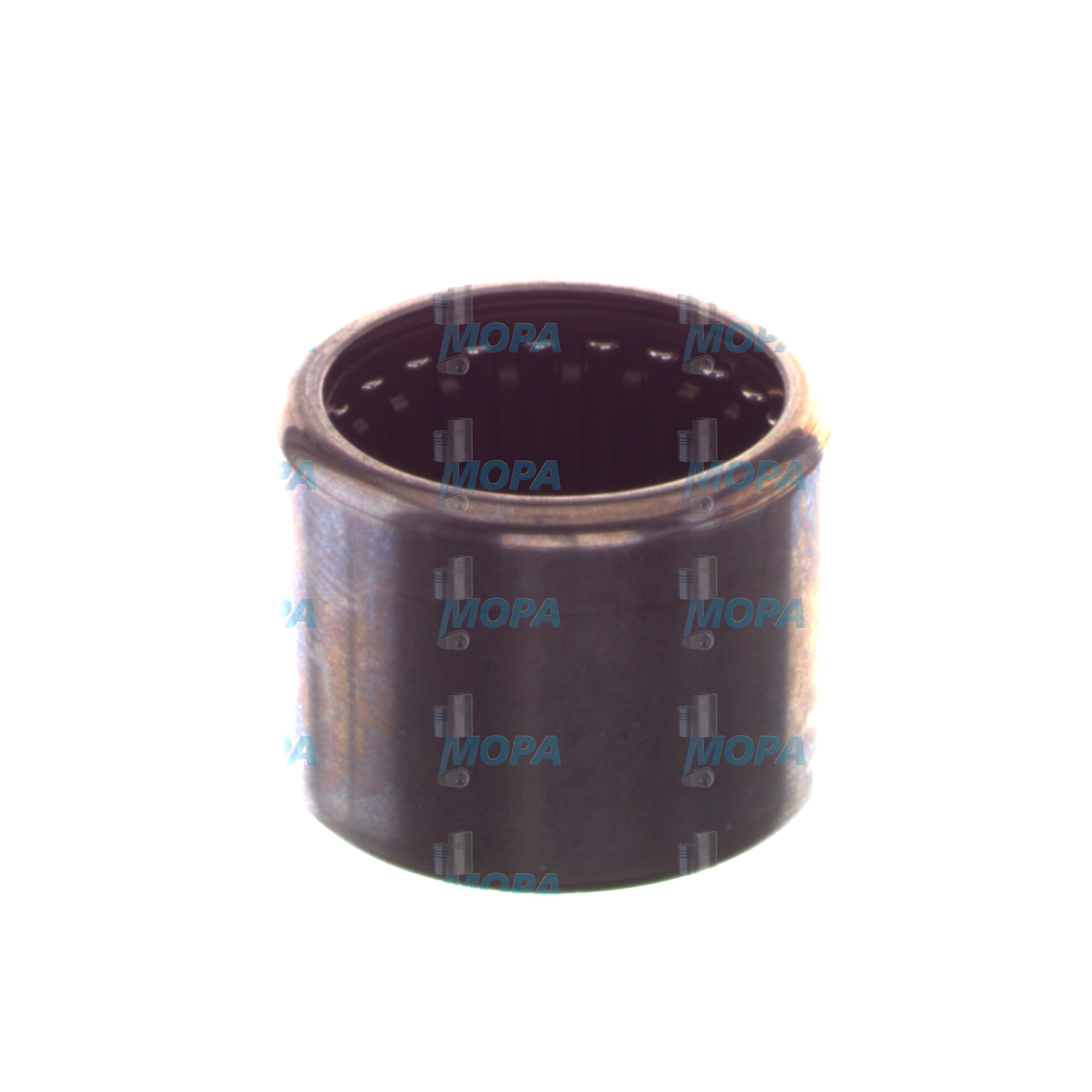

NEEDLE BUSH and Other Engine Components for Marine and Diesel Applications

The article category Other covers a wide range of precision components that do not fit into a single functional group but are vital for the correct operation of marine and diesel engines. These include items such as the NEEDLE BUSH, spacers, shims, dowel pins, thrust washers, plugs, retainers, and clips—small parts with big impact. In heavy-duty powertrains, these components ensure accurate alignment, low-friction motion, proper sealing, and consistent load transfer. Without them, even the best crankshaft, cylinder head, or turbocharger cannot reach its design performance. For shipowners, operators, and technical buyers, the Other category represents the connective tissue that keeps complex assemblies running with predictable reliability and efficiency.

Technical function of Other components with NEEDLE BUSH in a diesel engine

Within the Other category, the NEEDLE BUSH is a compact rolling-element bushing engineered to carry high radial loads in tight spaces. In a diesel engine or marine engine, it is frequently found in rocker arm pivots, fuel pump drives, governor linkages, auxiliary drives, and gear train idlers. Its cage or full-complement needle rollers create a line contact that distributes load more effectively than plain sleeves, reducing friction and heat at critical interfaces. This results in smoother valve-train dynamics, more stable injection timing, and lower parasitic losses—direct contributors to efficiency and durability.

Properly specified NEEDLE BUSH OEM parts are produced from high-grade bearing steels (e.g., through- or case-hardened), with controlled hardness profiles, roundness, and surface finish (typical Ra in the low micrometer range). Precision tolerances on wall thickness and bore geometry ensure the required interference fit, true running, and correct lubrication film formation. In corrosive marine environments, coatings or stainless variants can extend service life. Lubrication grooves, cages, and end flanges may be incorporated depending on duty cycle, speed, and load.

Other components in this category complement the NEEDLE BUSH by positioning, spacing, or retaining moving parts. Shims and spacers set axial clearances, dowel pins maintain alignment between housings, and thrust washers manage axial loads. Together, these parts secure dimensional stability under thermal expansion, vibration, and shock loads common in propulsion and auxiliary diesel engine systems.

- · High load capacity in compact envelopes via NEEDLE BUSH design

- · Reduced friction and heat for stable engine efficiency

- · Tight tolerances for accurate alignment and smooth operation

- · Materials and heat treatment tailored to marine engine duty

- · Corrosion-resistant options for salt-laden environments

- · Reliable lubrication control for extended service intervals

- · Precise shimming and spacing for correct clearances

- · Robust locating/retaining elements to resist vibration

Why Other components are critical for engine reliability and service life

Small deviations in supporting parts can cascade into major failures. A worn NEEDLE BUSH in a rocker pivot introduces lash and erratic valve motion, degrading combustion, raising exhaust temperatures, and accelerating wear on cams and followers. In a fuel pump drive, excessive radial play increases timing scatter, which elevates emissions and fuel consumption. Misaligned idlers or linkages can cause noise, vibration, and harshness, with potential damage to gears and shafts.

Similarly, missing or out-of-tolerance shims and spacers alter axial preload, leading to thrust face wear, oil leakage, or bearing overheating. Loose dowel fits allow housing shift; over time, the resulting misalignment stresses seals and bearings. In marine engines, where load cycles and environmental contamination are severe, these small parts form the first line of defense against unplanned downtime and high lifecycle cost. Keeping the Other category in optimum condition sustains service intervals, protects major components, and safeguards operational safety at sea.

Advantages of OEM spare parts suitable for Other (including NEEDLE BUSH)

Selecting OEM spare parts for the Other category—especially a NEEDLE BUSH for a diesel engine or marine engine—preserves the engineered stack-up that the equipment was designed around. Dimensional accuracy, heat treatment depth, roundness, and roller grade determine how forces are transmitted and how lubrication films form under load. OEM spare parts are manufactured to the exact drawing and validation criteria that match the target engine family, enabling consistent performance and predictable wear patterns.

For purchasing and technical teams focused on total cost of ownership, the benefits are practical: reduced fitting time due to correct tolerances; lower risk of rework; preserved emissions compliance thanks to stable timing and valve actuation; and protection of major assets such as camshafts and gear trains. Documentation, batch traceability, and quality control protocols support confident lifecycle management and fleet standardization.

- · Drop-in fit that preserves design clearances and preloads

- · Stable performance across temperature and duty cycles

- · Proven materials and heat treatment for long service life

- · Lower downtime and predictable maintenance planning

- · Traceability and consistent quality across global fleets

- · Optimized cost over lifecycle, not just at purchase

MOPA as your partner for OEM parts in the Other category

MOPA is an experienced, reliable partner for OEM spare parts in the Other category, including NEEDLE BUSH solutions for diesel and gas engines. We combine technical expertise with fast sourcing and secure logistics to support shipowners, operators, and service companies worldwide. Our team cross-references part numbers, validates applicability by engine type, and helps define the correct configuration—caged vs. full complement, sealed vs. open, material options—based on your duty profile.

Fast, quality-focused supply of NEEDLE BUSH OEM parts

Speed, quality, and transactional security are at the core of MOPA’s process. We provide prompt quotations, clear lead times, and dependable delivery windows to keep docks and yards on schedule. Every batch follows stringent quality checks and traceability requirements. For planned overhauls, MOPA can pre-kit Other components—NEEDLE BUSH, shims, spacers, pins, and washers—so technicians receive exactly what they need, minimizing installation risk and turnaround time.

Conclusion: NEEDLE BUSH and Other components matter

The Other category may be diverse, but its impact on engine stability and efficiency is decisive. A correctly specified NEEDLE BUSH and its complementary components protect major assemblies, maintain timing accuracy, and reduce friction under demanding marine and diesel engine conditions.

Choosing OEM spare parts suitable for the Other category ensures fit, reliability, and consistent performance, helping fleets run safely, efficiently, and within budget across the entire service life of the engine.