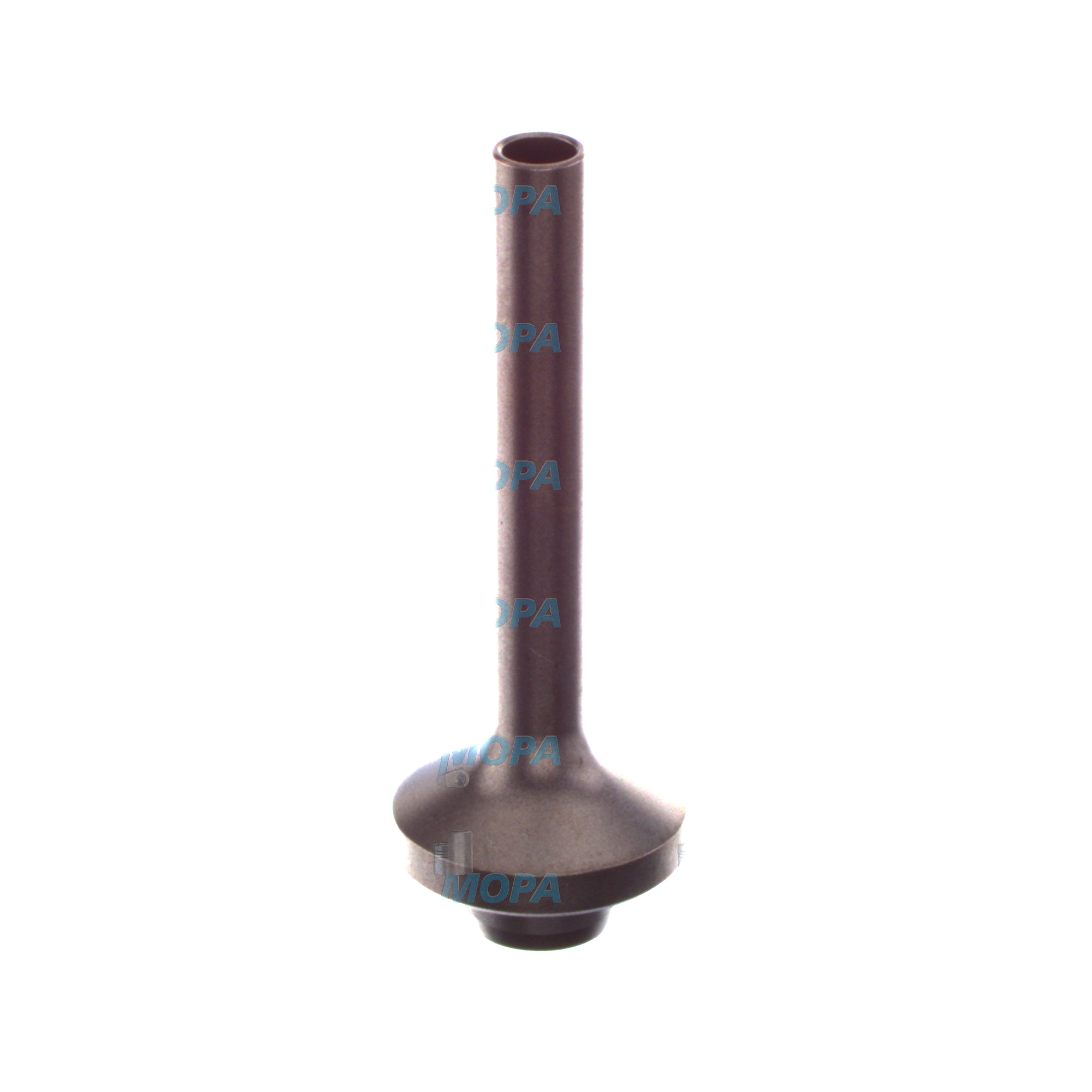

PLUNGER

PLUNGER solutions for the “Other” category in marine and diesel engine applications

The “Other” category brings together highly specialized engine components that do not fit into mainstream groups but are essential to dependable operation. This category covers precision parts such as the PLUNGER and barrel pairs used in fuel systems, along with pins, spacers, shims, sleeves, couplings, retainers, and various small mechanisms that enable accurate timing, sealing, guidance, and protection. Although compact, these components carry out critical tasks that keep marine and diesel engines efficient, safe, and compliant—making the “Other” category a strategic focus for maintenance planners and technical buyers.

Among these parts, the PLUNGER stands out as a core element in many injection pumps. Its micro-fitted interaction with the barrel is fundamental to building injection pressure, controlling delivery quantity, and shaping the combustion profile. When sourced and maintained correctly, these “Other” components stabilize performance across a wide range of duty cycles, fuels, and ambient conditions, from harbor maneuvering to full sea load.

Technical function of “Other” components with a focus on PLUNGER in diesel and marine engine systems

Within a diesel engine’s fuel system, the PLUNGER converts cam-driven mechanical motion into hydraulic pressure. As the cam lifts the tappet, the PLUNGER rises in its lapped barrel, reducing chamber volume and pressurizing the fuel to the high levels needed for fine atomization. Helical grooves and control edges on the PLUNGER regulate start and end of delivery, enabling precise timing and metering across the speed/load map. In a marine engine, this precise metering is vital to maintain stable specific fuel oil consumption and to control emissions under varying sea states and ambient temperatures.

Beyond the injector pump core, “Other” components fulfill equally important roles: shims set injection timing, sleeves ensure concentric alignment, pins and keys transmit torque without backlash, and seals protect against fuel leak-back that would otherwise reduce injection pressure. Together, these parts form a tightly integrated system where a micron-level deviation can cascade into poor spray patterns, hard starting, or accelerated wear of nozzles and pump elements.

Modern applications demand robust PLUNGER performance. In high-duty diesel engine operation, PLUNGER OEM parts are engineered for thermal stability, anti-scuff behavior, and low leakage at operating temperature. Surface finishes are optimized to minimize boundary friction, while heat treatment and materials selection resist micro-seizure during transient load steps. For marine engine operators, this translates into consistent ignition quality, smoother cylinder pressure profiles, and reduced smokiness during low-load harbor legs.

Key characteristics of the “Other” category (including PLUNGER components):

· Precision fits with micrometer-level clearances for stable pressure build-up.

· Hardened, wear-resistant surfaces to reduce scuffing and scoring.

· Optimized surface finish for low friction and minimal leakage.

· Materials and treatments tailored to heavy fuel and distillate operation.

· Reliable timing control via shims, pins, and coupling elements.

· Consistent atomization that supports efficiency and emissions compliance.

· Compatibility with diverse pump designs and control strategies.

Why the “Other” category is critical for reliability and service life

Reliability in large diesel and gas engines depends on the smallest tolerances. A worn PLUNGER or an out-of-spec shim can shift timing, degrade injection pressures, and upset combustion symmetry across cylinders. Consequences range from elevated fuel consumption and cylinder temperature imbalance to visible smoke, fouling, and unplanned downtime. Leak-back past a worn PLUNGER/barrel pair reduces effective injection pressure, causing poor atomization, incomplete burn, and higher soot loading. Scoring on functional surfaces can accelerate injector nozzle wear and destabilize idle or low-load operation—scenarios that directly impact safety and the vessel’s commercial availability.

In addition, misalignment due to fatigued sleeves or pins may increase vibration and load on adjacent components, shortening bearing life and risking secondary failures. Left unaddressed, minor deviations in these “Other” parts can become costly interventions, including frequent injector overhauls, fuel system flushing, or even cylinder component replacement.

Advantages of OEM spare parts suitable for the “Other” category and PLUNGER assemblies

Choosing OEM spare parts for the “Other” category—particularly for PLUNGER assemblies—delivers consistent fit and predictable performance. Dimensional fidelity, validated materials, and controlled surface treatments help maintain the tight clearances needed for efficient pressure generation. This ensures that timing, delivery quantity, and spray quality remain within specification throughout the service interval.

For technical buyers, the value is clear: reliable PLUNGER OEM parts reduce troubleshooting time, stabilize KPIs such as SFOC and exhaust opacity, and support planned maintenance cycles. Traceable production and test documentation provide confidence in metallurgy, heat treatment, and microfinish quality. The result is reduced risk of rework, faster commissioning after overhauls, and fewer surprises during sea trials.

From a budget perspective, correct-fit components minimize collateral wear, extend service intervals, and help avoid costly schedule disruptions. For fleet managers balancing OPEX and compliance, this selection approach sustains component lifetimes while protecting combustion quality under varying load profiles.

MOPA as your partner for OEM spare parts in the “Other” category, including PLUNGER components

MOPA is a trusted partner for sourcing OEM parts across the “Other” category with a strong track record in diesel and gas engine applications. Customers benefit from fast response, precise cross-referencing, and secure handling—from inquiry to delivery. Whether you require a single PLUNGER for a marine engine injection pump or a complete kit including sleeves, pins, shims, and seals, MOPA prioritizes speed, quality, and transactional security.

Our team supports technical identification, provides documentation where applicable, and coordinates logistics worldwide to minimize downtime. By focusing on OEM parts for critical functions, MOPA helps maintenance teams achieve first-time-right overhauls, preserve engine efficiency, and maintain consistent operating margins.

Conclusion: “Other” category relevance and PLUNGER OEM parts

The “Other” category encompasses high-precision components that quietly secure the performance backbone of marine and diesel engines. Among them, the PLUNGER plays a decisive role in fuel pressure generation and clean combustion.

Selecting OEM spare parts suitable for the “Other” category—especially for PLUNGER assemblies—protects performance, reliability, and lifecycle costs. With MOPA, you gain a responsive partner focused on speed, quality, and security in the supply of OEM parts for diesel and gas engines.

Discover the Plunger with Comparison Number 02280458 Discover the Plunger with comparison number 02280458, a quality product that is ideally suited for the requirements of MWM & Deutz engines. This spare part belongs to the "Other" category and plays a key role in the reliability of your engines, particularly in marine and stationary applications.OEM Spare Parts for Your Needs The Plunger is an OEM spare part that meets the high standards of the industry, thereby offering maximum efficiency for engines. With spare parts that are compatible with MWM & Deutz, you can rely on proven quality and ensure that your machines run smoothly.

Reliable Plunger with Comparison Number 02030860 Discover our plunger with the comparison number 02030860, which proves to be an indispensable OEM spare part. This precise component is suitable for the optimal functioning of your MWM & Deutz engines. The stability and reliability of these engines are crucial, which is why we provide you with an excellent solution through our plunger, specially designed for use in marine and stationary applications.Optimal Dimensions for Various Applications Weighing only 0.026 kg and with compact dimensions of 2 cm in length, 2 cm in width, and 5.5 cm in height, the plunger can be effortlessly utilized in tight installation conditions. Our product is suitable for the series 640 and 540, as well as the engine types BV12M640, BVM540, and RBV8M540. This versatility makes the plunger a true all-rounder for various application scenarios.

Plunger 12210772: Perfect Fit for EnginesThe plunger with the comparison number 12210772 is an essential spare part that ensures your engines work together optimally. This OEM spare part impresses with its highest precision and quality tailored to your needs, which is important for performance optimization. By using products from the Original Equipment Manufacturer (OEM), you increase the reliability of your machines, especially when it comes to high-performance applications.Reliability through Compatible Part for MWM & DeutzThis product is specifically designed and suitable for MWM & Deutz engines, particularly for the engine type TBD645-L6. The spare part offers an exact fit, ensuring optimal performance and longevity. With a length of 7 cm, a width of 7 cm, and a height of 2 cm, the plunger fits perfectly into your system and allows for quick installation. Your engines benefit immediately from the correct attachment and, consequently, from increased stability.

Innovative Plunger for EnginesDiscover the plunger with the comparison number 12188688, specifically designed for MWM & Deutz engines suitable for their application area. With a weight of only 0.04 kg, this product is an efficient and reliable OEM replacement part that is optimally tailored to meet the demands of your engines. As part of the "Other" product category, it represents an important component to ensure the performance of your machines.Replacement Part with Lasting QualityThe plunger is an OEM replacement part that meets the strict criteria set by the manufacturers. This ensures high quality and durability, providing stable operation for all MWM & Deutz engines. Rely on our many years of experience in supplying engine replacement parts.

Precise Performance: Plunger suitable for MWM & DeutzDiscover the plunger with the comparison number 02286825, a top-quality product specifically designed for MWM & Deutz engines. This OEM replacement part is the ideal solution for your engines and ensures smooth operation. The precise workmanship ensures that the plunger meets all the requirements expected from excellent replacement parts.Lightweight with Remarkable FunctionalityWeighing only 0.02 kg, the plunger is not only lightweight but also particularly robust and durable. Suitable for MWM & Deutz engines, this OEM replacement part provides reliable performance in various applications. Rely on our product to maximize the efficiency of your system.

Precise Spare Parts for Efficient EnginesThe comparison number 606907641001 designates our reliable plunger, an essential component that is suitable for MWM & Deutz engines. This product from the article group "Other" optimizes the functionality of your engines by ensuring the highest precision in application. Weighing only 0.04 kg, this plunger is not only lightweight but also environmentally friendly, making it ideal for a variety of applications, whether in the maritime sector or in stationary operations.

Plunger – Comparison Number 04070640Discover the premium plunger with the comparison number 04070640, which is ideal for precise applications in your machine. This OEM replacement part is suitable for MWM & Deutz engines, particularly in the series 628. The engine types compatible with this plunger include the BV16M628, SBV16M628, SBV8M628, and SBV9M628, allowing you to achieve maximum performance with the correct replacement part.

Product Description: Precise OEM Replacement PlungerDiscover our plunger with the comparison number 358/119/127, suitable for MWM & Deutz engines. This precise product is specially designed for the needs of series 640 and 540. Furthermore, it fits the engine types BV12M640, BVM540, and RBV8M540. Weighing only 0.026 kg and with compact dimensions of 2 cm in length, 2 cm in width, and 5.5 cm in height, the plunger can be easily integrated into any existing engine configuration.Maximum Fit Accuracy for Your EquipmentOur plunger falls under the category of Other and meets the highest quality standards. OEM stands for Original Equipment Manufacturer and ensures optimal compatibility with engines from MWM & Deutz. You can trust that our product provides all necessary features to ensure long-lasting performance and a perfect fit for your engines. With our commitment to excellent quality, you can rely on the reliability of this replacement part.

Quality Product: Plunger as OEM Replacement PartDiscover the Plunger (comparison number 350/119/127), an essential replacement part that is perfectly suited for your needs with MWM & Deutz engines. With this comparison number, we ensure that you receive a product that meets specific performance and safety requirements. Benefit from over 25 years of experience in providing OEM replacement parts.Custom Dimensions: Suitable for Many SeriesThe Plunger is compatible with the series 640 and 540, according to the manufacturers MWM & Deutz. With its compact dimensions – 2 cm in length and 2 cm in width, as well as 5.5 cm in height – this replacement part offers high flexibility in your application. Additionally, the low weight of just 0.026 kg ensures that installation proceeds smoothly in various applications. Rely on the qualities of our products, which are always manufactured according to the latest standards.

1. Precise Replacement Part for MWM & Deutz EnginesDiscover our OEM replacement part, the plunger with the comparative number 628/19/8/05061507, which is perfectly suited for MWM & Deutz engines. This plunger ensures that your engines operate efficiently and deliver optimal performance. The quality and durability of this product offer a reliable solution for various applications, whether stationary or maritime.2. Compact Dimensions for Easy IntegrationThe plunger, suitable for the series 628, impresses with compact dimensions: 9.9 cm in length and width, a height of 2 cm, and a weight of only 0.031 kg. This lightweight and handy OEM replacement part not only allows for effortless installation but also reduces complexity when replacing it in your engines. Rely on its premium design during installation and use.

PLUNGER with the comparison number 02270177 suitable for MWM & Deutz engines

Reliable Plunger suitable for MWM & Deutz enginesDiscover our product, the plunger (comparison number 628/19/8/05062110), an indispensable OEM replacement part that has been precisely designed for MWM & Deutz engines. Trust in the strong performance and stability that this plunger offers you to ensure that your engines operate optimally. With dimensions of 9.9 cm in length and width, as well as a height of 2 cm, this replacement part is designed to integrate seamlessly into the system.