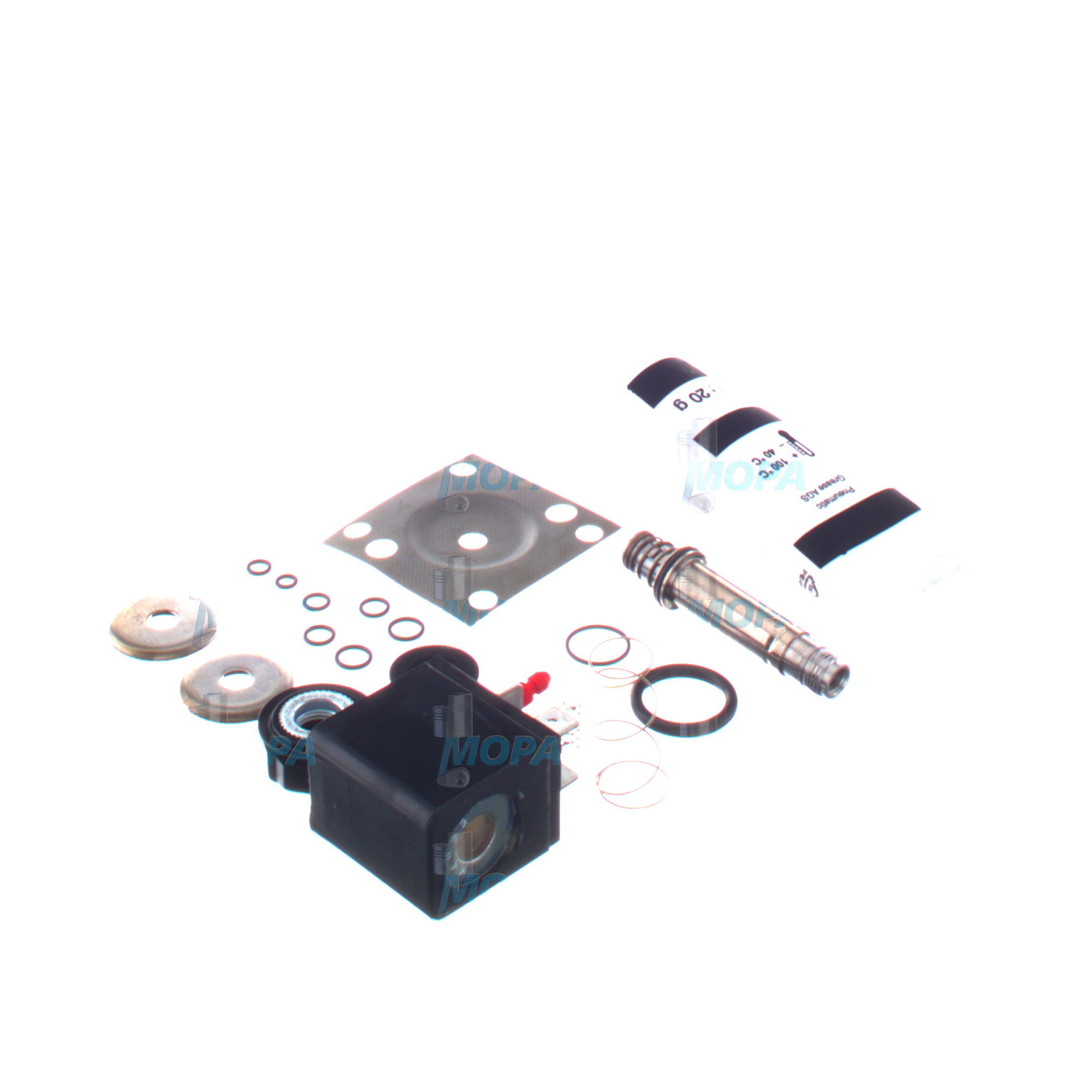

REPAIR KIT solutions for Other engine components

The article category “Other” covers the many auxiliary components that keep diesel and gas engines operating safely and efficiently: sealing elements, small wear parts, fastening hardware, hoses, fittings, sensors, and service consumables. These parts may be compact, but they are fundamental to pressure retention, fluid management, vibration control, and system monitoring. Without them, the main assemblies of a marine engine or power-plant drive cannot achieve stable performance or predictable maintenance cycles.

In practice, the “Other” category provides the connective tissue of the engine: gaskets and O‑rings preserve compression and prevent leakage; clamps and bolts hold systems in alignment; filters and strainers protect precision components; valves and hoses guide fuel, oil, and coolant; senders and switches deliver the data that operators and automation systems rely on. A well-matched REPAIR KIT for a diesel engine consolidates many of these items into a ready-to-use set, reducing downtime and ensuring that each service task is completed to specification.

Technical function of “Other” components and the REPAIR KIT in diesel engine and marine engine applications

Each item in the “Other” category serves a targeted functional purpose. Seals and gaskets maintain the integrity of combustion, lubrication, and cooling circuits—critical for heat transfer, friction control, and emissions. Fasteners and bushings preserve alignment of rotating equipment, protecting bearings and minimizing vibration. Hoses and fittings manage flow rates and prevent cavitation in cooling and fuel systems. Sensors, switches, and minor electrical accessories enable accurate pressure, temperature, and level feedback so that safety limits and control loops work as intended.

A REPAIR KIT for a marine engine typically bundles the precise O‑rings, gaskets, crush washers, guide pins, filters, and fasteners required for a defined service scope—such as a cooling water pump overhaul, fuel injection pump reseal, charge-air cooler service, or valve cover refresh. Using a REPAIR KIT OEM parts set streamlines planning and reduces the risk of missing components during port calls or planned outages. In a diesel engine, that same kit structure helps technicians execute work instructions correctly the first time, with consistent torque values, material compatibility, and dimensional fits across all mating surfaces.

- · Sealing integrity: gaskets and O‑rings that preserve pressure, vacuum, and fluid separation.

- · Flow control: hoses, fittings, and valves sized for the required temperatures and media.

- · Fastening and alignment: bolts, studs, and bushings that hold tolerances under load.

- · Monitoring: senders and switches that feed accurate data to engine control and safety systems.

- · Thermal and chemical resistance: materials selected for oils, fuels, coolants, and exhaust gas.

- · Service-ready packaging: REPAIR KIT combinations tailored to specific engine tasks and intervals.

Importance for engine operation, reliability, and safety

“Other” components and their associated REPAIR KIT options are pivotal for uptime. A single degraded seal can lead to oil loss, coolant ingress, or fuel leakage—issues that escalate into bearing damage, liner scoring, overheating, or even engine-room hazards. Incorrect fasteners or worn bushings can create misalignment, increasing vibration and accelerating wear of pumps, alternators, and ancillary drives. Aging hoses and clamps invite weeping at connections, reducing system pressure and compromising cooling efficiency. Faulty senders distort control decisions, potentially pushing the engine outside safe operating limits.

Keeping these parts in proper condition stabilizes combustion quality, keeps fluids where they belong, and maintains the accuracy of protective instrumentation. For shipowners and plant operators, that translates into predictable service intervals, lower total fuel and lube consumption, fewer unplanned stops, and consistent compliance with class and emissions requirements.

Advantages of OEM spare parts suitable for “Other” components and REPAIR KIT OEM parts

Selecting OEM spare parts suitable for the “Other” category and using a REPAIR KIT for a diesel engine delivers measurable benefits across performance, reliability, budget, and service life. Dimensional consistency ensures sealing faces mate perfectly; elastomers match the chemical profile of marine fuels, bio-blends, coolants, and high-temperature oils; and metallics carry the correct hardness and corrosion resistance. Documentation and traceability support quality audits, while consistent packaging helps crews execute maintenance quickly and correctly.

Performance and reliability

With REPAIR KIT OEM parts, technicians receive the exact springs, seats, spacers, and seals specified for the assembly. That precision preserves flow rates in cooling and fuel circuits, restores pump efficiency, and maintains the torque retention of fasteners—directly supporting engine output and stability under varying loads and sea states.

Budget and life-cycle efficiency

Bundled kits reduce procurement complexity, minimize express shipments for forgotten small parts, and cut rework caused by mismatched dimensions or incompatible materials. Correct sealing and alignment extend component life, spacing out overhauls and reducing the cumulative cost of spares, labor, and downtime over the vessel’s or plant’s operating horizon.

MOPA as a partner for OEM spare parts in the “Other” category

MOPA is an experienced, reliable partner for OEM spare parts in the “Other” category and for every REPAIR KIT required around diesel and gas engines. Customers rely on MOPA for speed—short lead times and efficient consolidation; for quality—parts sourced to exact engine-maker specifications with clear documentation; and for security—controlled supply chains, rigorous inspection, and transparent traceability in the trade of OEM parts for marine engine and stationary applications.

Whether you need a REPAIR KIT for a cooling water pump, gasket sets for cylinder covers, or the precise sensors and fittings for a fuel module, MOPA streamlines procurement and keeps your maintenance on schedule.

Conclusion: why “Other” and the right REPAIR KIT matter

The “Other” category comprises the critical small components that make big engines dependable. Keeping these parts up to spec with a correctly curated REPAIR KIT for marine engine and diesel engine maintenance preserves sealing integrity, flow control, and instrumentation accuracy. Choosing OEM spare parts suitable for this category enhances performance, reliability, and service life while optimizing maintenance budgets and minimizing downtime.