WEIGHT focus for the “Other” engine parts category

The article category “Other” covers a broad range of auxiliary engine components that do not fall into classic groups like pistons, injectors, or turbochargers—but are nonetheless critical to reliable operation. These items include seals and gaskets, fastening hardware, brackets, clamps, hoses, cable harness accessories, thermal shields, anti-vibration mounts, protective covers, and various small fittings. In heavy-duty diesel and marine engine applications, these seemingly minor elements control leakage paths, stabilize assemblies, manage thermal loads, and secure sensors and lines—functions that directly influence uptime, efficiency, and safety.

Because powertrains are complex systems, the integration and WEIGHT distribution of parts in the “Other” category affect alignment, vibration behavior, and service accessibility. Correct mass and mounting points for a WEIGHT marine engine installation, for example, depend on brackets and mounts that are dimensionally correct and consistent in stiffness. Likewise, reliable sealing and fastening of auxiliary systems keeps fluids where they belong and prevents unplanned downtime.

WEIGHT and technical function of “Other” parts in diesel engine and marine engine systems

Components in the “Other” category provide foundational support functions that make core engine parts perform as intended. Sealing elements (NBR/FKM O-rings, MLS gaskets, PTFE seals) prevent oil, coolant, and boost-air losses that degrade combustion quality and raise operating costs. Fasteners (studs, bolts, nuts per ISO 898 / ISO 3506) ensure stable clamp loads so thermal cycles do not loosen joints. Brackets and guards, typically in coated steel or 316L stainless for corrosion resistance, position accessories at the correct datum and protect personnel. Hoses and clamps maintain charge-air and coolant integrity under pressure and temperature, supporting turbo efficiency. Anti-vibration mounts and flexible couplings tune system stiffness and damping, helping to control torsional oscillations and protect bearings. Harness clips, conduits, and connectors safeguard signals from abrasion and heat, maintaining sensor accuracy.

These functions directly impact performance metrics. A small leak downstream of the turbo reduces boost, increasing fuel consumption. Incorrect mount stiffness shifts natural frequencies, amplifying vibration and shortening component life. A misaligned accessory bracket can influence belt tracking, raising parasitic losses and risking belt failure. In short, the “Other” group preserves the designed clearances, pressures, and alignments that high-output diesel engines depend on. During installation and service, attention to WEIGHT diesel engine accessory mounting—through correct brackets, shims, and mounts—keeps shafts in line, which reduces coupling wear and heat generation.

Functional clusters within “Other” and their impact on WEIGHT OEM parts selection

When specifying or replacing parts, consider material compatibility, temperature and pressure ratings, surface treatments, and dimensional tolerances. Matching the validated specification is crucial for sealing longevity, stable clamp load, corrosion resistance, and vibration behavior. This is where WEIGHT OEM parts selection minimizes risk: validated geometry and materials ensure predictable behavior under real-world loads.

- · Precise fit and tolerance control keep alignment true and vibrations low.

- · Correct elastomer and gasket materials resist fuels, oils, and coolants.

- · Coated fasteners and stainless clamps deliver high corrosion resistance.

- · Rated hoses and couplings maintain pressure and temperature integrity.

- · Engineered mounts tune stiffness/damping to protect bearings and frames.

- · Thermal shields and wraps reduce heat soak and protect nearby components.

- · Certified electrical routing prevents chafe, shorts, and signal loss.

- · Documented traceability supports class and safety compliance.

Why “Other” parts are critical for reliability and engine service life

The service life of a diesel or gas engine depends on controlling leakage, vibration, heat, and alignment. Worn seals lead to oil dilution, reduced lubrication film, and bearing distress. A failed charge-air hose causes turbo overspeed or fouled emissions equipment. Loose or under-strength fasteners permit joint movement, fretting, and crack initiation. Degraded mounts pass higher vibratory loads into the block and foundation, accelerating fatigue in brackets and pipework. Missing or damaged heat shields raise under-hood temperatures, aging elastomers and electronics prematurely. Even minor bracket misalignments can cause belt dusting, alternator overload, or coolant pump wear—small issues that cascade into downtime.

Failure indicators and maintenance priorities

Look for oil mist around joints, coolant crust at hose tails, belt residue, rivulet marks on shields, flattened or cracked rubber mounts, and chafing at harness tie points. Thermal discoloration near guards signals heat migration. Addressing these early—using correct torque sequences, replacing aged elastomers, and refreshing clamps and mounts—protects the main investment. For marine installations, periodic checks of foundation bolts and alignment shims are vital, as hull flex and load changes can shift the effective WEIGHT distribution and alter vibration modes.

Advantages of OEM spare parts suitable for “Other”

Choosing OEM spare parts suitable for the “Other” category preserves the engineered system behavior the engine was designed for. Dimensional fidelity ensures brackets and guards align without stressing threads or bending fasteners. Material specifications—such as FKM for high-temperature oil seals, EPDM for coolant hoses, or 316L for saltwater exposure—are matched to the duty profile. Surface treatments and coatings maintain clamp load and resist corrosion in humid, saline, or chemically aggressive environments. Validation testing confirms cold-start sealing, heat soak, and duty-cycle vibration performance, which in turn stabilizes efficiency and reduces the likelihood of secondary damage.

From a budget perspective, correctly specified components reduce rework and prevent collateral failures that drive up labor and downtime. Consistent parts quality keeps maintenance intervals predictable and supports safe operation across fleets.

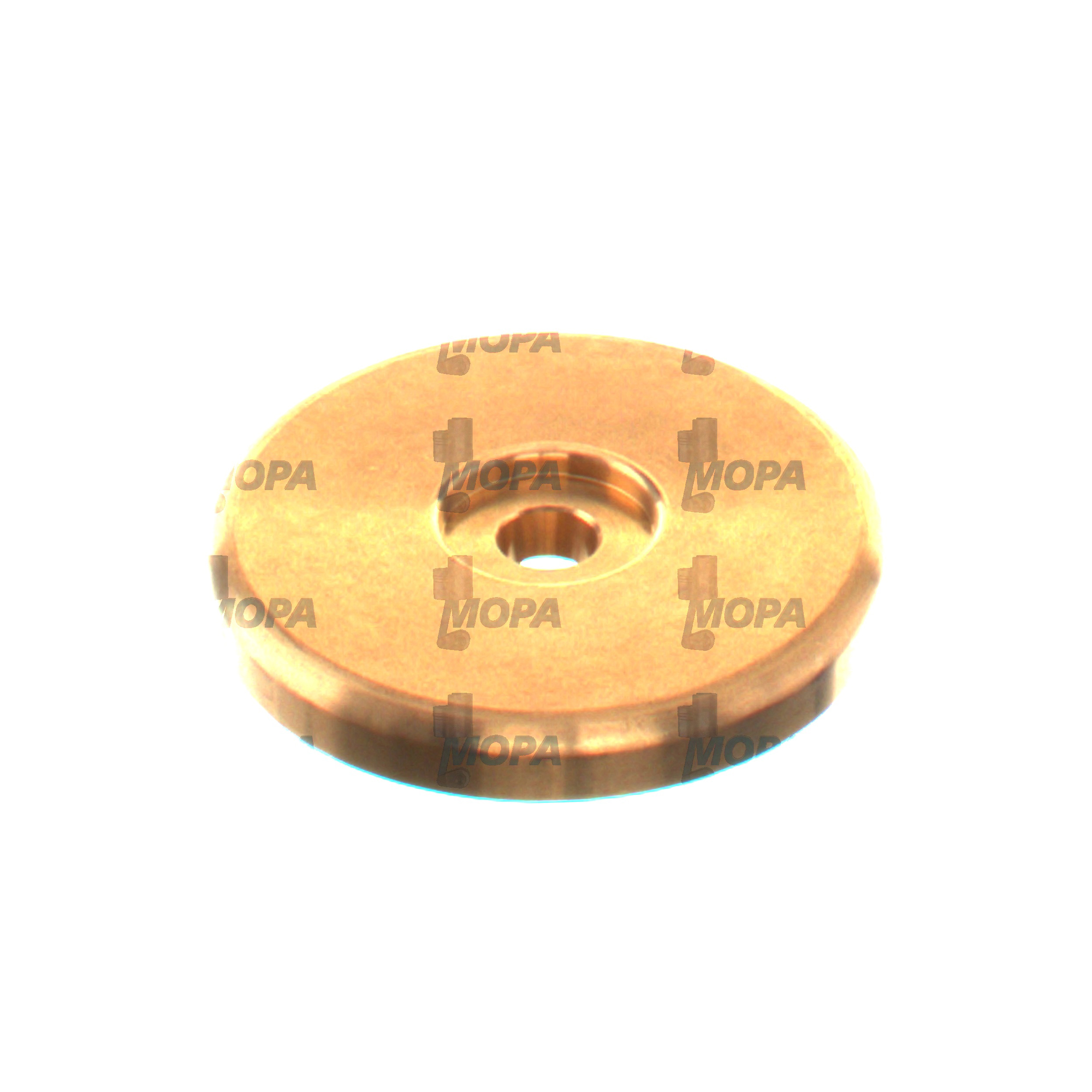

MOPA: your partner for OEM spare parts in the “Other” category

MOPA is an experienced and reliable partner for OEM spare parts in the “Other” category, supplying the small but decisive components that keep diesel and gas engines operating at peak performance. We prioritize speed in sourcing and logistics, quality in specification adherence, and security in the trade of OEM parts—backed by documentation and traceability suitable for industrial and marine use. Whether you need seals, mounts, brackets, clamps, or protective hardware, MOPA streamlines procurement for single units and fleet programs alike, helping you reduce downtime and maintain consistent performance.

Conclusion

The “Other” category forms the backbone of dependable engine operation by controlling leakage, alignment, vibration, and heat. Choosing OEM spare parts suitable for this category safeguards performance, supports efficiency, and extends service life—across WEIGHT marine engine installations and high-duty diesel platforms alike. Partner with MOPA to secure fast, reliable access to the right parts, every time.